Precision Fire Protection News

Growth in Codes and Standards is Essential to Safety within Cannabis Oil Extraction Facilities

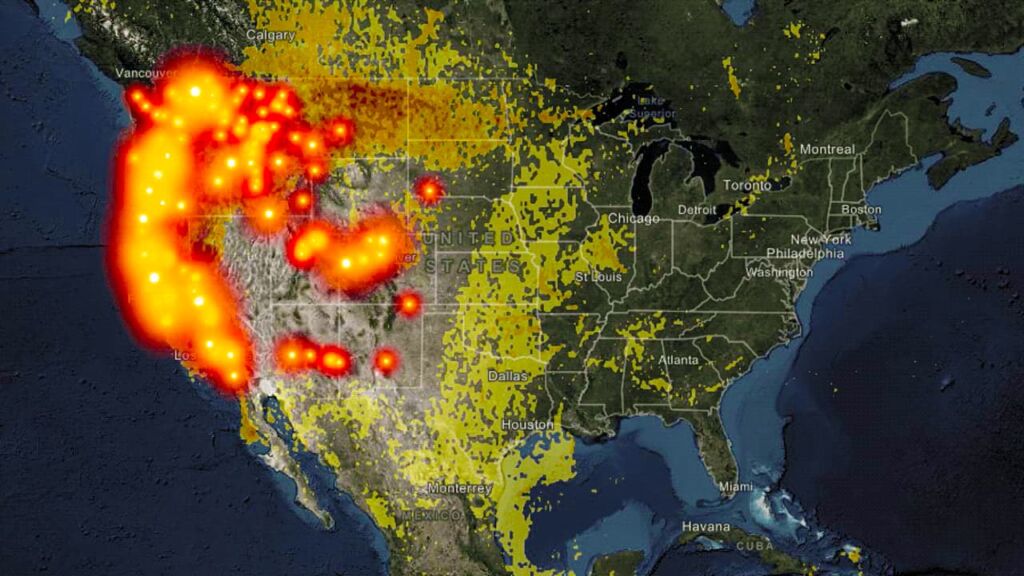

Both the cannabis plant and the industry itself have been growing quite a bit over the past decade. In 2012, Colorado and Washington became the first two states to legalize recreational use of cannabis. Many other states followed suit. As of November 2022, a total of 21 states, and the District of Columbia, had approved the use of cannabis for recreational purposes.

Both the cannabis plant and the industry itself have been growing quite a bit over the past decade. In 2012, Colorado and Washington became the first two states to legalize recreational use of cannabis. Many other states followed suit. As of November 2022, a total of 21 states, and the District of Columbia, had approved the use of cannabis for recreational purposes.

Legalization provided many people with an opportunity to use cannabis to treat conditions such as pain, migraines, depression, and anxiety, among other things, while remaining law-abiding citizens. With the increase in demand came a need for an increase in supply.

Facilities of all shapes and sizes began popping up in states where cannabis was legalized to be manufactured. While cannabis is commonly smoked by many users, other forms of cannabis products include gummies, oils, supplements, and extracts. These products are manufactured by extracting cannabidiol (CBD) and tetrahydrocannabinol (THC) from the plant itself.

What are the safety concerns?

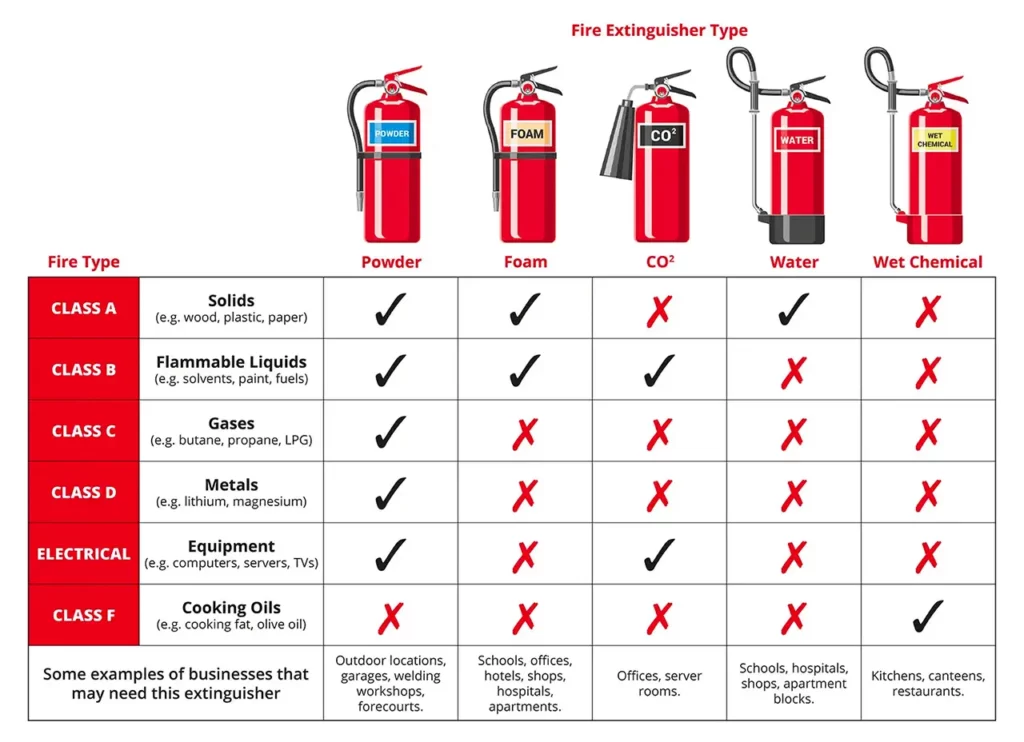

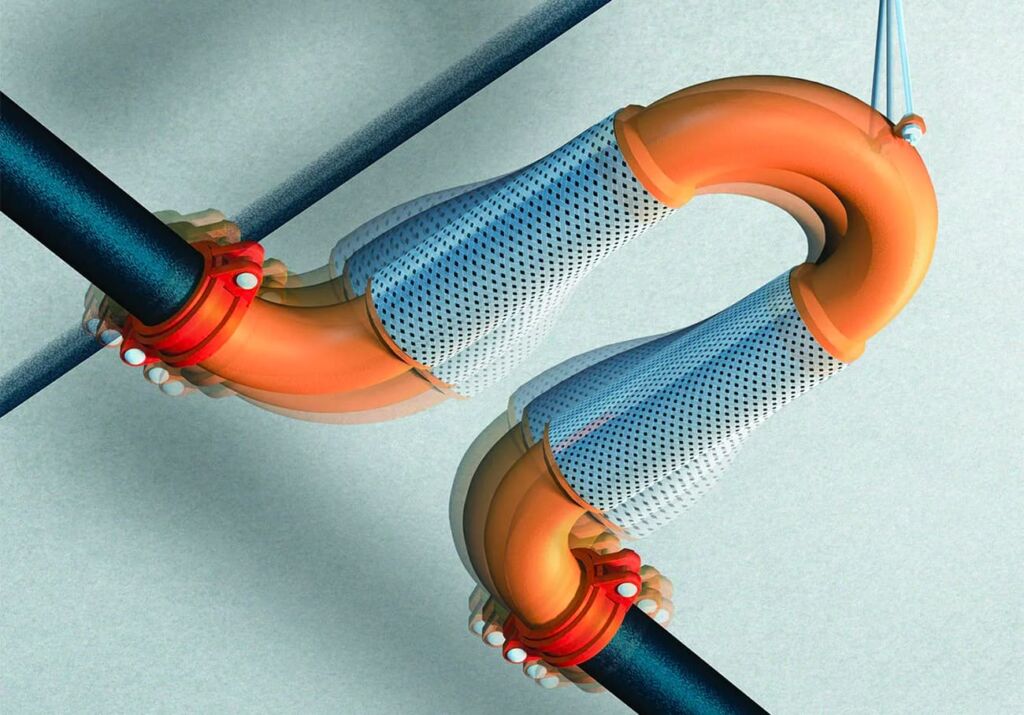

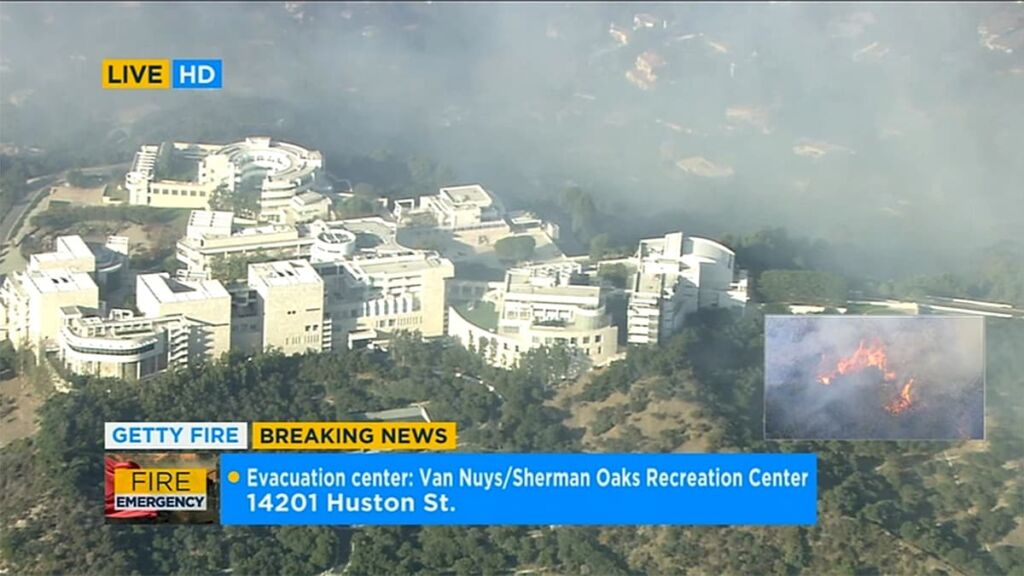

The extraction of cannabis oil can pose many safety issues, including the risk of fire and explosion. In many cases, the extraction process itself creates a hazardous location due to the use of flammable solvents such as butane, pentane, hexane, propane, and ethanol, which can all be released during the processing and extraction of plant oils. Proper installation, maintenance, and use of the extraction equipment employed as part of the processing of oils from cannabis will go a long way in achieving overall safety within these types of facilities.

RELATED

• Listen to an NFPA podcast about regulating the cannabis industry

• Read, “The New Face of Pot,” published in the July/August 2018 NFPA Journal

What does the NEC say?

The 2023 edition of NFPA 70®, National Electrical Code® (NEC®), made significant strides toward helping achieve electrical safety in facilities that perform cannabis oil extraction by adding Article 512, Cannabis Oil Equipment and Cannabis Oil Systems Using Flammable Materials.

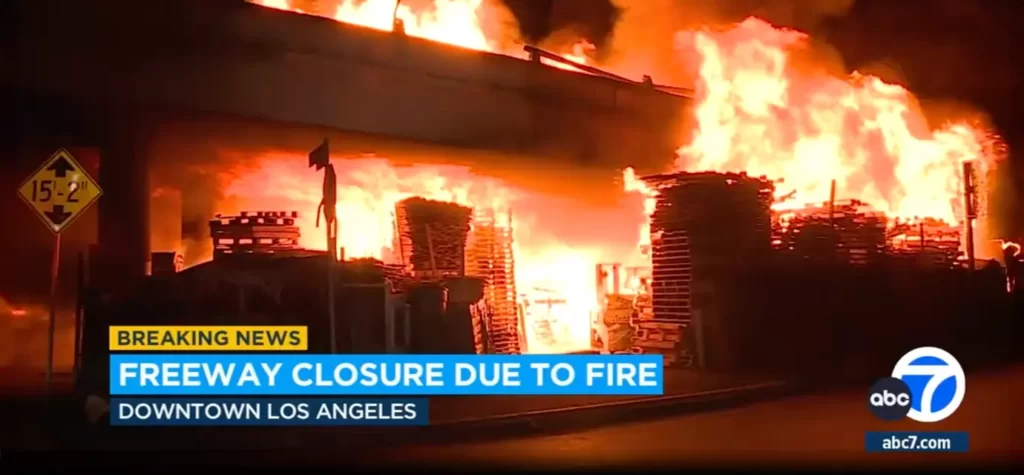

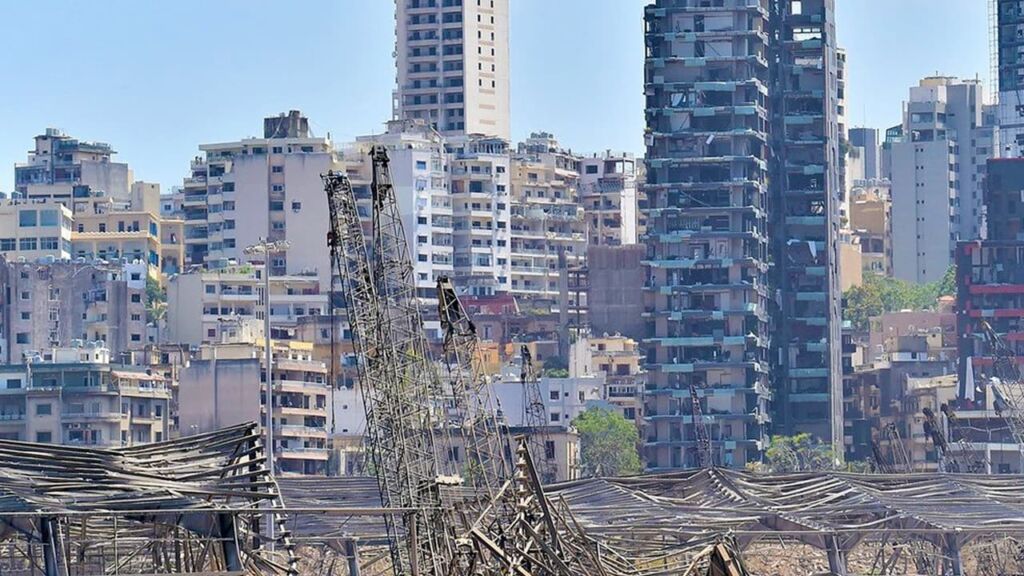

This new article provides electrical requirements for cannabis oil preparatory equipment, extraction equipment, booths, post-processing equipment, and systems using flammable materials (flammable gas, flammable liquid–produced vapor, combustible liquid–produced vapor) in commercial and industrial facilities. A public input that was submitted for the 2023 NEC as part of the NFPA standards development process, PI-2285, supported creating a new article that would “elevate the level of safety” within the cannabis industry. The substantiation of PI-2285 provided examples of real-life explosion incidents within cannabis facilities, some of which required more than 200 firefighters to battle the blaze and left large numbers of firefighters injured. In an industry that has processes and procedures unfamiliar to many authorities having jurisdiction (AHJs) and that continues to see tremendous growth, it is crucial to provide safety requirements around installations that can be verified at the time of inspection.

While it is likely that we will see new Article 512 expand within future NEC cycles to provide more guidance, the initial content contained within the 2023 NEC begins to provide some of the necessary requirements for designers, installers, and AHJs to achieve electrical safety around cannabis equipment and systems.

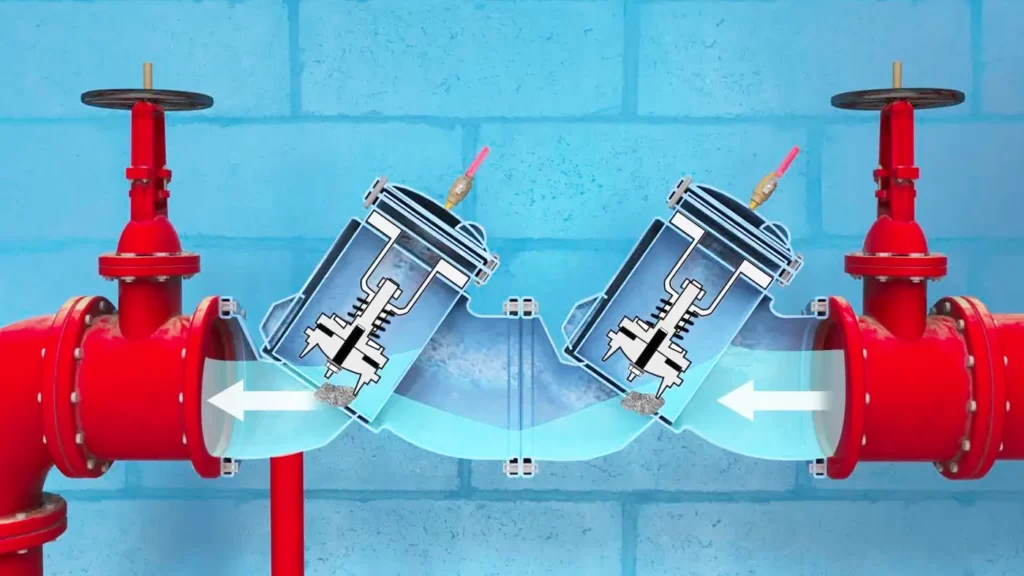

Article 512 is broken down into three parts: Part I: General; Part II: Wiring; and Part III: Equipment. Section 512.3 is a key component for installations as it provides the requirements for how cannabis oil equipment and systems that can release flammable materials during operation must be classified. The section is broken down into Part A, which covers installations outside of booths, and Part B, which covers installations within booths. Each of these areas are then further broken down into installations where flammable gases and vapors are released and installations where flammable gases and vapors are not released.

Having the area classified properly is an important initial step as we move into Parts II and III of Article 512 to determine how wiring and equipment installations must be performed in and around the hazardous locations. Part III, in particular, includes requirements for the equipment and systems to be listed and marked. It also provides guidance on when gas detection is required.

While the new Article 512 within the 2023 NEC is a great starting point for beginning to provide electrical safety requirements within cannabis facilities, as can be expected, safety needs don’t stop there.

A new, dedicated cannabis standard

Currently, NFPA is in the development stages of NFPA 420, Standard on Fire Protection of Cannabis Growing and Processing Facilities. The overall goal of NFPA 420 is to address the protection of facilities where cannabis is being grown or processed from fire and related hazards. Initial meeting minutes found at the NFPA 420 document information page reflect committee task groups working to develop preliminary chapters that provide information pertaining to fundamentals, indoor growing, drying/processing, and extraction. Provided that the draft development progresses at the technical committee level, and approval to do so is provided by the NFPA Standards Council, the goal is to have an initial NFPA 420 document available for public input sometime in 2024.

The growth of the cannabis industry does not show any signs of slowing down. A recent article in Forbes stated that market research firm BDSA is forecasting cannabis sales in the United States to grow from $25 billion in 2021 to $40 billion in 2026. More facilities, more processing, and more workers lead to an increased need for safety within the cannabis industry. Continued development of codes and standards that provide knowledge for those designing, performing, and inspecting these installations is paramount to achieving a high level of safety within cannabis growing and processing facilities.

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

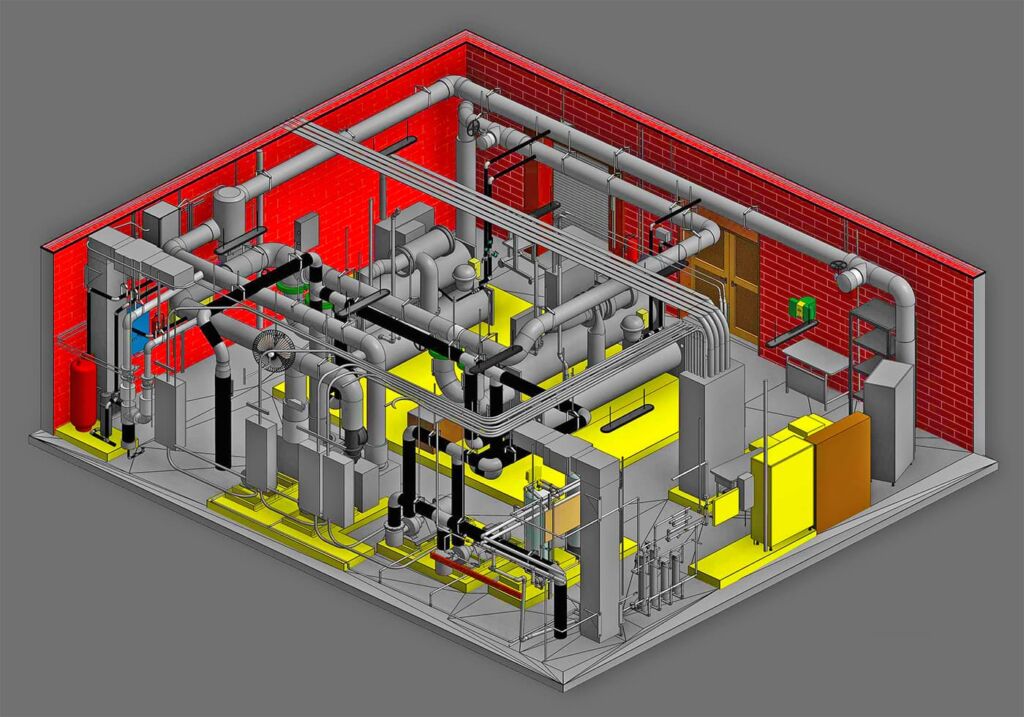

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.