Precision Fire Protection News

Sprinkler Types and Inspection Schedules

Sprinkler Types and Inspection Schedules

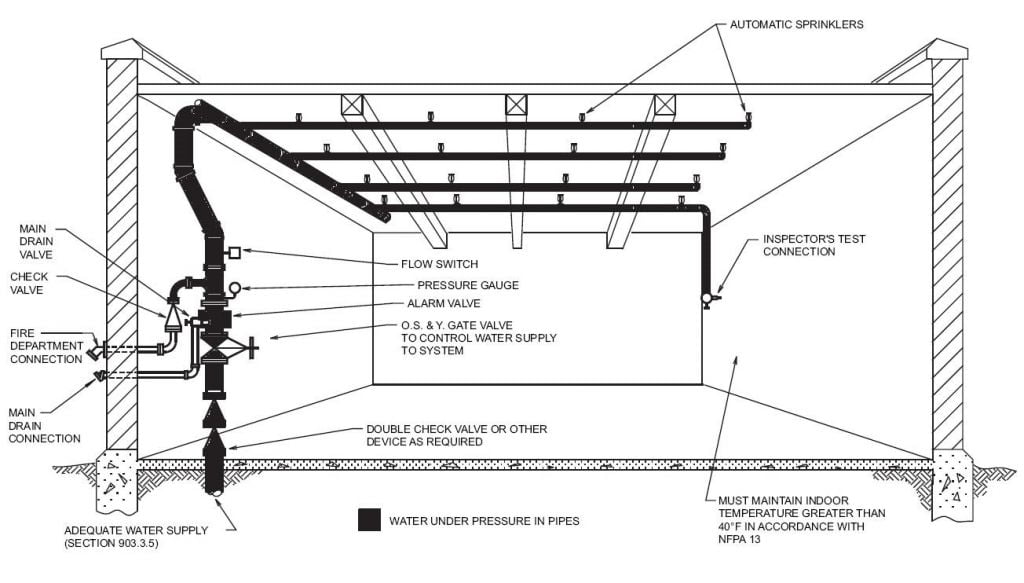

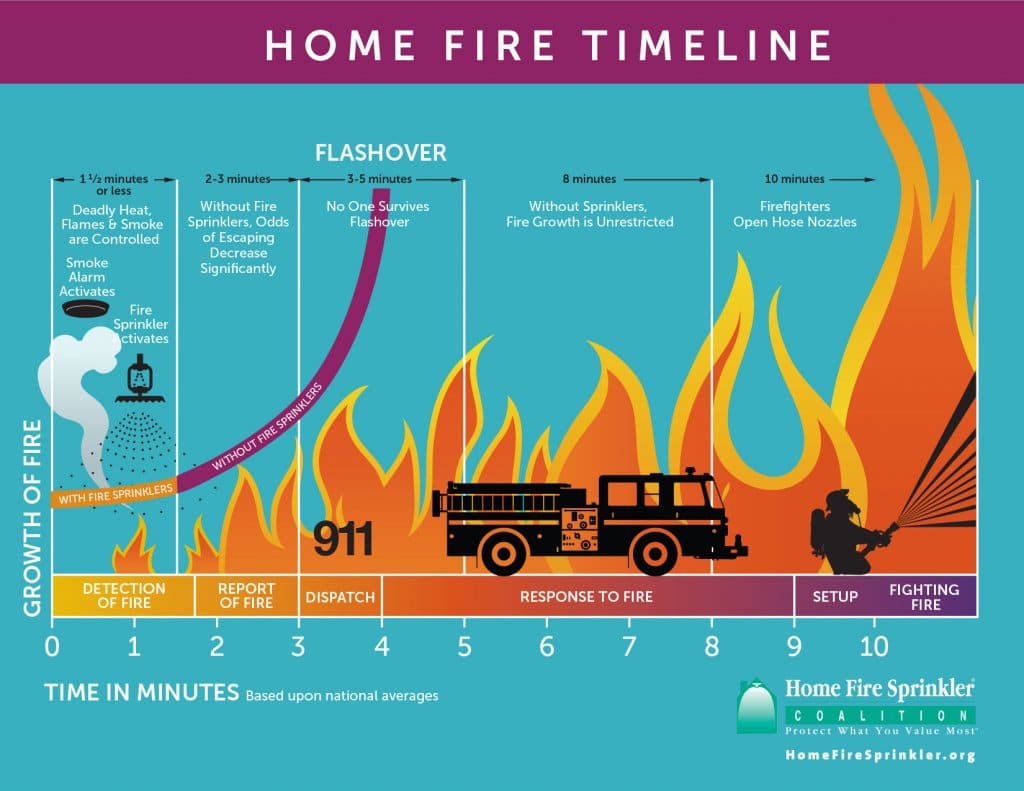

Wet – Wet type systems are the most common type of sprinkler system that is installed. A wet pipe system has water in the pipes in the ambient or normal condition and has heat responsive elements on all sprinklers. Thus, water is instantaneously discharged from a sprinkler when it actuates.

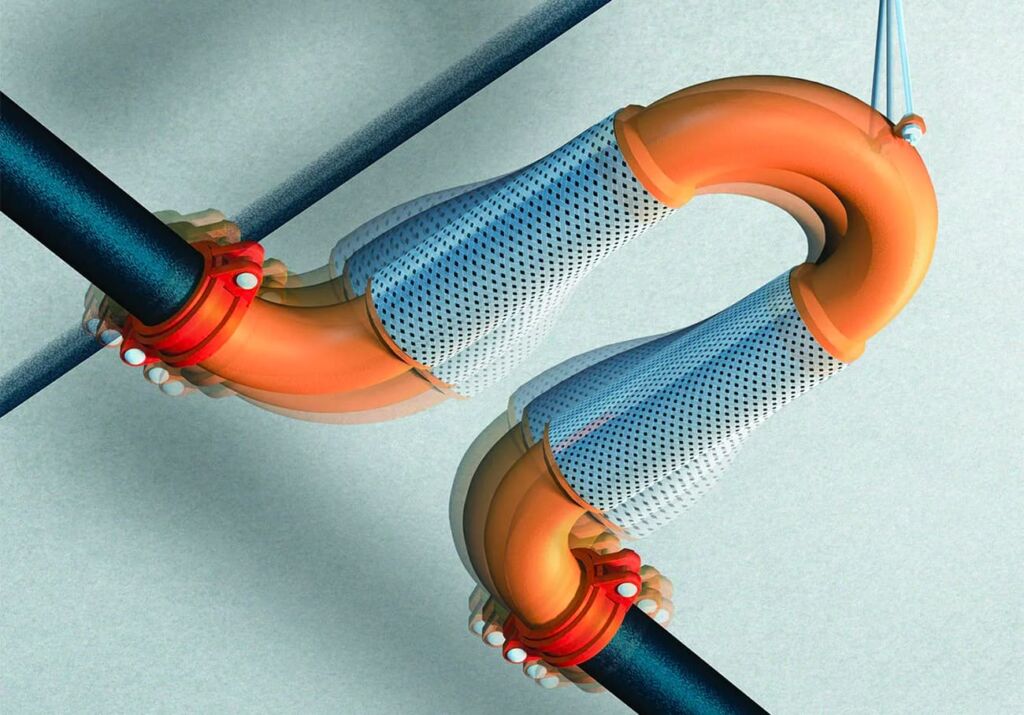

Dry – In areas where low temperatures could cause a wet pipe system to freeze, a dry pipe system is intended for use. Dry pipe systems are pressurized with air in the ambient condition and experience an inherent delay in the discharge of water to allow the pressurized air in the system to escape. When a sprinkler actuates, air is released through the sprinkler, allowing water to flow into the piping system through the dry pipe valve. NFPA 13 mandates that the time for the water to reach the most remote sprinkler be no longer than 60 seconds. This time delay allows the fire to grow larger than it would with a wet pipe system of similar design, and the larger fire size results in more sprinklers in the fire area actuating.

To limit the size of dry pipe systems, a volumetric limitation with a maximum capacity of 750 gallons is placed on dry pipe systems. A quick opening device, such as an accelerator or an exhauster, is installed to rapidly remove air from the system and speed the operation of the dry pipe valve and is required when the system volumetric capacity exceeds 500 gallons.

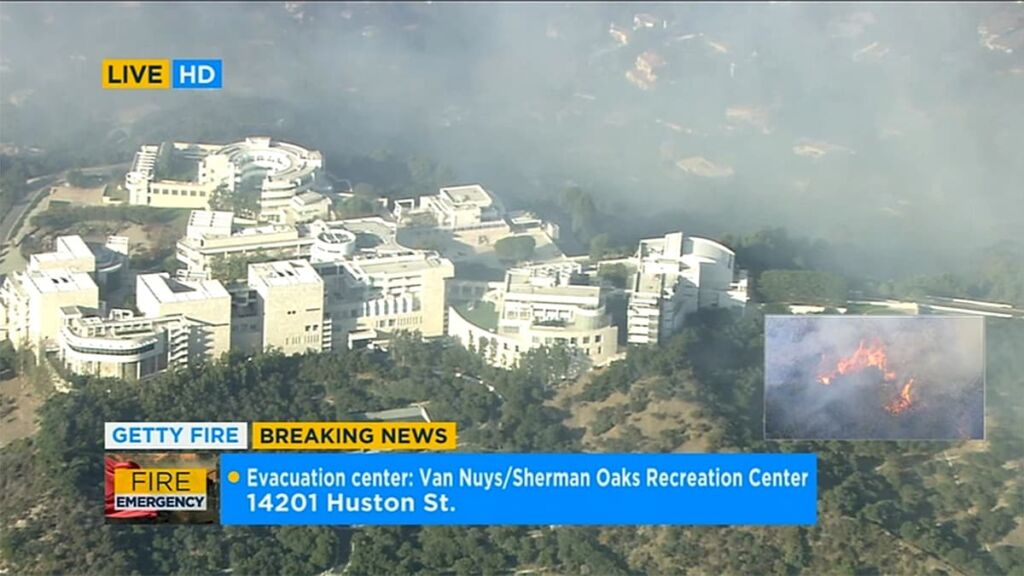

Preaction and Deluge – Preaction systems and deluge systems required fire detectors (smoke, heat, etc.) for the actuation of the system. A deluge system uses open sprinklers or nozzles, so that all flow water is discharged when the deluge valve actuates. Deluge systems can be used for occupancies where the hazard is considered severe, such as with flammable liquid hazards where the fire could spread over a large floor area.

Preaction system have closed heads and pipes filled with pressurized air that supervise a piping system, and can be considered for the protection of valuable assets or irreplaceable property. The detection system for a preaction system can be designed to prevent water discharge in cases of a false alarm from the detection system, or in case of a sprinkler whose element has encountered mechanical damage.

The detection system on a preaction system can be designed with a preaction logic capable of meeting one of the following objectives:

-Actuation of a fire detector trips a deluge valve to admit water into the sprinkler piping to await the actuation of a sprinkler.

-Actuation of a fire detector or actuation of a heat-responsive element on a sprinkler trips a deluge valve to admit water into the sprinkler piping.

-Actuation of a fire detector and actuation of a heat-responsive element on a sprinkler trips a deluge valve to admit water into the sprinkler piping.

Sprinkler Head Types

Spray sprinklers are manufactured in three basic styles. A standard spray upright (SSU) sprinkler is mounted on upright above a branch line pipe, usually in a room with exposed structural elements, and has a deflector, a metal plate whose edge is distinctively bent to deflect water downward from the sprinkler. A standard spray pendant (SSP) sprinkler is mounted below the branch line, usually mounted at or below the surface of a suspended ceiling and is characterized by a flat deflector. SSU and SSP discharge patterns are designed to be the same. Sidewall sprinklers have a specifically designed deflector that allows the sprinkler to discharge water from a wall-mounted position.

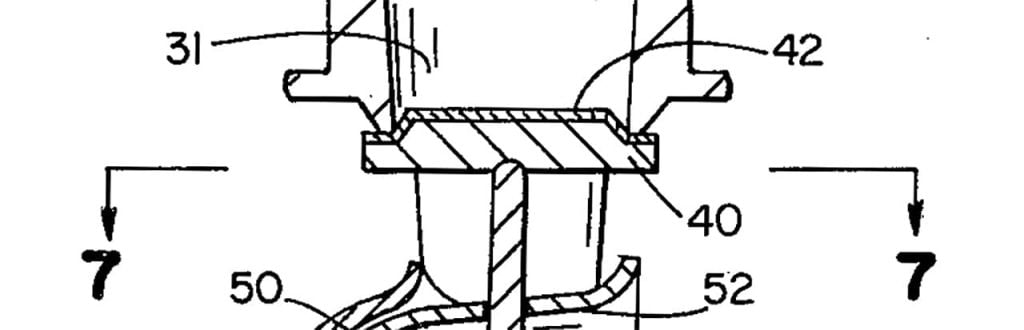

Variations on upright, pendant, and sidewall sprinkler are the dry upright, dry pendant, and dry sidewall sprinklers. These special sprinklers are manufactured with a seal at the inlet that prevents water from entering the nipple until the sprinkler actuates. These sprinklers can be extended from a wet pipe system into an unheated area, such as a walk-in freezer, an outside loading dock, or an unheated attic space, or can be used in the pendant position on a dry pipe system to prevent condensation from entering the sprinkler and freezing.

Pendant Head Upright Head Sidewall head Concealed Head

Dry Pendant Head

Sprinkler Head Temperature Ratings

|

Max Ceiling Temperature (F) |

Head Temperature Rating (F) |

Temperature Classification |

Color Code |

Glass Bulb Color |

|

100 |

135-170 |

Ordinary |

Uncolored or Black |

Orange or Red |

|

150 |

175-225 |

Intermediate |

White |

Yellow or Green |

|

225 |

250-300 |

High |

Blue |

Blue |

|

300 |

325-375 |

Extra High |

Red |

Purple |

|

375 |

400-475 |

Very Extra High |

Green |

Black |

|

475 |

500-575 |

Ultra High |

Orange |

Black |

|

625 |

650 |

Ultra High |

Orange |

Black |

Sprinkler Coverage

Another development in sprinkler manufacturing is the extended coverage sprinkler. The deflectors on these sprinklers are designed to discharge water over larger areas than standard sprinklers. While this means that each sprinkler must have a higher flow, it results in increased allowable distance between sprinklers, with the possibility that fewer sprinklers may be required in a compartment given size.

Sprinkler Responses

A major development in sprinkler technology was the quick response sprinkler, a sprinkler with a specially designed response element that allows the rapid transfer of heat to the heat-responsive element and provides a more expeditious delivery of water to the fire. At the time of sprinkler actuation, the fire should be smaller with a quick response sprinkler than with a standard response sprinkler, resulting in fewer sprinklers likely to actuate. Sprinkler elements are either glass bulbs or eutectic (soldered) elements.

The response of quick response and standard response sprinklers can be modeled by designers to estimate the time for a sprinkler to actuate, given ceiling height, fire size, and response time index (RTI), using the DETACT computer program, developed by the Building and Fire Research Laboratory at the National Institute of Standards and Technology (NIST). Response time index is a measure of the sensitivity of a sprinkler heat responsive element, with low RTI values being very sensitive to actuation by heat, and high RTI values being less sensitive.

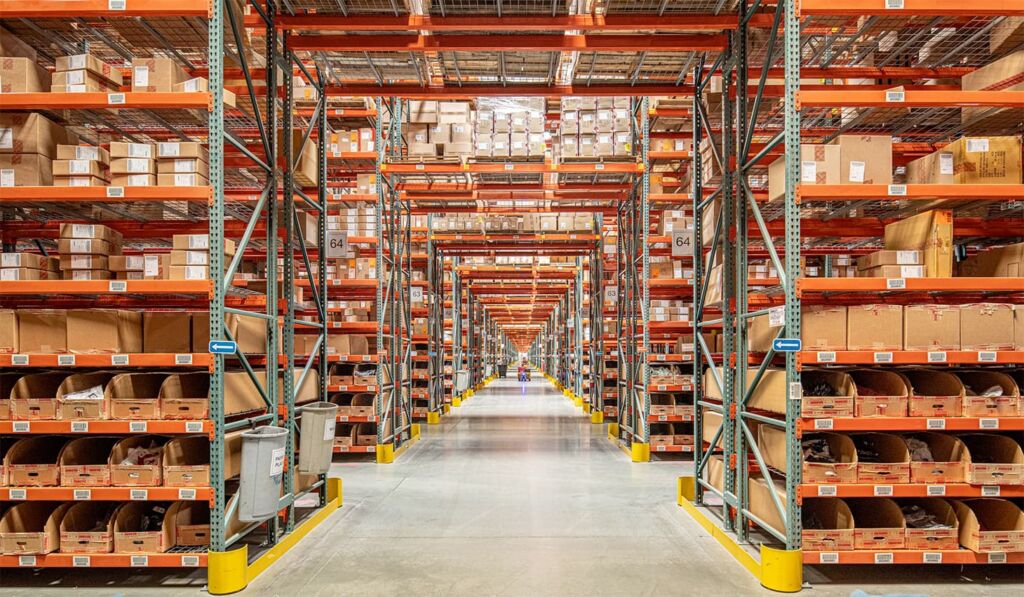

Sprinkler for Storage Applications

ESFR and large Drop sprinklers are for specialized high challenge fire hazards. An ESFR sprinkler has a quick response element and an extra large orifice that allows for greater amounts of water to be applied early in the fire development, usually on a high challenge fire. Large drop sprinklers have large deflectors with widely spaced teeth to facilitate the creation of large water drops intended to penetrate a high velocity fire plume without evaporating, resulting in some water reaching the burning materials. The fire plume is the column of smoke and gas traveling upward from a fire.

Sprinkler System Inspection Requirements

NFPA requires that certain activities be performed at prescribed frequencies. However, rarely does an inspection and test agreement assign all of these activities and frequencies to a fire prevention company. To comply fully, an implied partnership is formed between the owner or the ownerʼs representative and the contractor. All of the requirements of NFPA 25 are the responsibility of the owner, and the contractor relies on the owner to perform all inspections and tests not specified in the agreement.

A common agreement for a wet sprinkler system will have the fire protection contractor coming to the building on an annual basis to conduct the annual inspections (See Below), while the owner or ownerʼs representative performs the quarterly, monthly, and weekly required inspections.

Unless specifically referenced in the agreement all other less-frequent activities are not included such as testing gauges every 5 years, testing sprinklers every 5, 10, 20, or 50 years; and internally inspecting alarm valve, check valves, strainers, filters, and orifices. These activities are normally performed by the fire protection contractor but are invoiced as additional periodic services.

Sprinkler System Inspection Frequencies

|

Device |

Activity |

Frequency |

|

Sprinkler System |

||

|

Gauges (Dry, Pre-Action, Deluge Systems) |

Inspection |

Weekly/Monthly |

|

Control Valves |

Inspection |

Weekly/Monthly |

|

Alarm Devices |

Inspection |

Quarterly |

|

Gauges (Wet Pipe Systems) |

Inspection |

Monthly |

|

Hydraulic Nameplate |

Inspection |

Quarterly |

|

Buildings |

Inspection |

Annually (prior to freezing) |

|

Hanger/Seismic Bracing |

Inspection |

Annually |

|

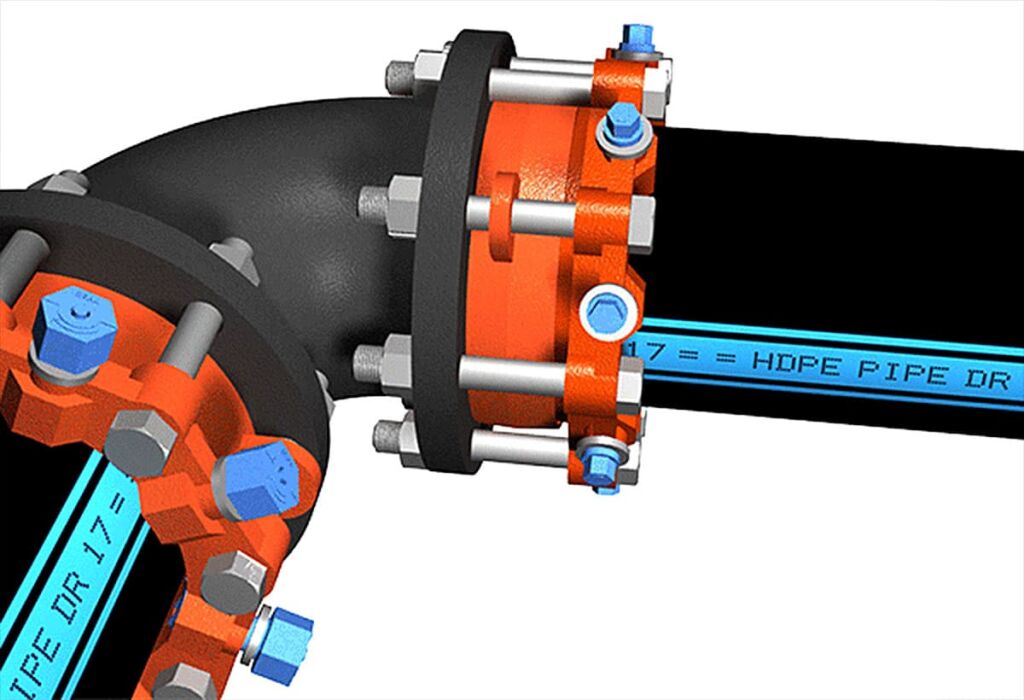

Pipe and Fittings |

Inspection |

Annually |

|

Sprinklers |

Inspection |

Annually |

|

Spare Sprinklers |

Inspection |

Annually |

|

Fire Department Connections |

Inspection |

Quarterly |

|

Alarm Devices |

Test |

Quarterly/Semi-Annually |

|

Main Drain |

Test |

Annually |

|

Anti-freeze Solution |

Test |

Annually |

|

Gauges |

Test |

5 years |

|

Sprinklers — Extra High Temperature |

Test |

5 years |

|

Sprinklers — Fast Response |

Test |

At 20 years and every 10 thereafter |

|

Sprinklers |

Test |

At 50 years and every 10 thereafter |

|

Valves |

Maintenance |

Annually or as needed |

|

Obstruction |

Maintenance |

5 years or as needed |

|

Low Point Drains (Dry Pipe Systems) |

Maintenance |

Annually prior to freezing and as needed |

|

Private Fire Service Main |

||

|

Hose Houses I |

nspection |

Quarterly |

|

Hydrants (Dry Barrel with Wall) I |

nspection |

Annually and after each operation |

|

Monitor Nozzle I |

nspection |

Semi-Annually |

|

Hydrants (Wet Barrel) I |

nspection |

Annually and after each operation |

|

Mainline Strainers I |

nspection |

Annually and after each significant flow |

|

Piping (Exposed) I |

nspection |

Annually |

|

Piping (Underground) I |

nspection |

See NFPA 25 |

|

Monitor Nozzle |

Test |

Flow Annually (Range and Operation) |

|

Hydrants |

Test |

Flow Annually |

|

Piping (Exposed and Underground) |

Flow Test |

5 years |

|

Mainline Strainers |

Maintenance |

Annually and after each operation |

|

Hose Houses |

Maintenance |

Annually |

|

Hydrants |

Maintenance |

Annually |

|

Monitor Nozzle |

Maintenance |

Annually |

|

Standpipe |

||

|

Control Valves I |

nspection |

Weekly/Monthly |

|

Pressure Regulating Devices I |

nspection |

Quarterly |

|

Piping I |

nspection |

Quarterly |

|

Hose Connections I |

nspection |

Quarterly |

|

Cabinet I |

nspection |

Annually |

|

Hose I |

nspection |

Annually |

|

Hose Storage Device I |

nspection |

Annually |

|

Alarm Device |

Test |

Quarterly |

|

Hose Nozzle |

Test |

Annually |

|

Hose Storage Device |

Test |

Annually |

|

Hose |

Test |

5 years/3 years |

|

Pressure Control Valve |

Test |

5 years |

|

Pressure Reducing Valve |

Test |

5 years |

|

Hydrostatic Test |

Test |

5 years |

|

Flow Test |

Test |

5 years |

|

Main Drain Test |

Test |

Annually |

|

Hose Connections |

Maintenance |

Annually |

|

Valves |

Maintenance |

Annually or as needed |

|

Water Storage Tanks |

|

Conditions of Water in Tank |

Inspection |

Monthly/Quarterly |

|

Water Temperature |

Inspection |

Daily/Weekly |

|

Heating System |

Inspection |

Daily/Weekly |

|

Control Valves |

Inspection |

Weekly/Monthly |

|

Water Level |

Inspection |

Monthly/Quarterly |

|

Air Pressure |

Inspection |

Quarterly |

|

Tank Exterior |

Inspection |

Quarterly |

|

Support Structure |

Inspection |

Quarterly |

|

Catwalks and Ladders |

Inspection |

Quarterly |

|

Surrounding Areas |

Inspection |

Annually |

|

Valves |

||

|

Control Valves |

||

|

Sealed |

Inspection |

Weekly |

|

Locked |

Inspection |

Monthly |

|

Tamper Switches |

Inspection |

Monthly |

|

Alarm Valves |

||

|

Exterior |

Inspection |

Monthly |

|

Interior |

Inspection |

5 years |

|

Strainers, filters, orifices |

Inspection |

5 years |

|

Check Valves |

||

|

Interior |

Inspection |

5 years |

|

Pre-Action/Deluge Valves |

||

|

Enclosure (cold) |

Inspection |

Daily/Weekly |

|

Exterior |

Inspection |

Monthly |

|

Interior |

Inspection |

Annually/5 years |

|

Strainers, Filters, Orifices |

Inspection |

5 years |

|

Dry Pipe Valves/Quick Opening Devices |

||

|

Enclosure |

Inspection |

Daily/Weekly |

|

Exterior |

Inspection |

Monthly |

|

Interior |

Inspection |

Annually |

|

Strainers, Filters, Orifices |

Inspection |

5 years |

|

Pressure Reducing and Relief Valves |

||

|

Sprinker System |

Inspection |

5 years |

|

Hose Connections |

Inspection |

Quarterly |

|

Hose Racks |

Inspection |

Quarterly |

|

Fire Pump |

Inspection |

Weekly |

|

Backflow Prevention Assemblies |

||

|

Reduced Pressure |

Inspection |

Weekly/Monthly |

|

Reduced Pressure Detectors |

Inspection |

Weekly/Monthly |

|

System Devices |

||

|

Fire Department Connections |

Inspection |

Quarterly |

|

Main Drains |

Test |

Annually/Quarterly |

|

Water-Flow Alarms |

Test |

Quarterly |

|

Control Valves |

||

|

Position |

Test |

Annually |

|

Operation |

Test |

Annually |

|

Supervisory |

Test |

Semi-Annually |

|

Pre-Action/Deluge Valves |

||

|

Priming Water |

Test |

Quarterly |

|

Low Air Pressure Alarm |

Test |

Quarterly |

|

Full Flow |

Test |

Annually |

|

Pre-Action/Deluge Valves |

||

|

Priming Water |

Test |

Quarterly |

|

Low Air Pressure Alarm |

Test |

Quarterly |

|

Full Flow |

Test |

Annually |

|

Dry Pipe Valves/Quick Opening Devices |

||

|

Priming Water |

Test |

Quarterly |

|

Low Air Pressure Alarm |

Test |

Quarterly |

|

Quick Opening Devices |

Test |

Quarterly |

|

Trip Test |

Test |

Annually |

|

Full Flow Trip Test |

Test |

3 years |

|

Pressure Reducing and Relief Valves |

||

|

Sprinkler System |

Test |

5 years |

|

Circulation Relief |

Test |

Annually |

|

Pressure Relief Valves |

Test |

Annually |

|

Hose Connections |

Test |

5 years |

|

Hose Racks |

Test |

Annually |

|

System Devices |

||

|

Backflow Prevention Assemblies |

Maintenance |

Annually |

|

Control Valves |

Maintenance |

Annually |

|

Pre-Action/Deluge Valves |

Maintenance |

Annually |

|

Dry Pipe Valves/Quick Opening Devices |

Maintenance |

Annually |

Building Ownerʼs Responsibility

As you know, testing and inspection of fire protection systems and devices is the responsibility of the building owner. NFPA 25 1998 Edition section 1-4.2 states “the responsibility for properly maintaining a water-based fire protection system shall be that of the owner(s) of the property. By means of periodic inspections, tests, and maintenance, the equipment shall be shown to be in good operating condition, or any defects or impairments shall be revealed. Inspection, testing, and maintenance shall be implemented in accordance with procedures meeting or exceeding those established in this document [NFPA 25] and in accordance with the manufacturer’s instructions. These tasks shall be performed by personnel who have developed competence through training and experience.”

Any sprinkler system deficiency or performance related issue shall be repaired by the building owner. NFPA 25 1998 Edition section1-4.4 states that “the owner or occupant promptly shall correct or repair deficiencies, damaged parts, or impairments found while performing the inspection, test, and maintenance requirements of this standard. Corrections and repairs shall be performed by qualified maintenance personnel or a qualified contractor.”

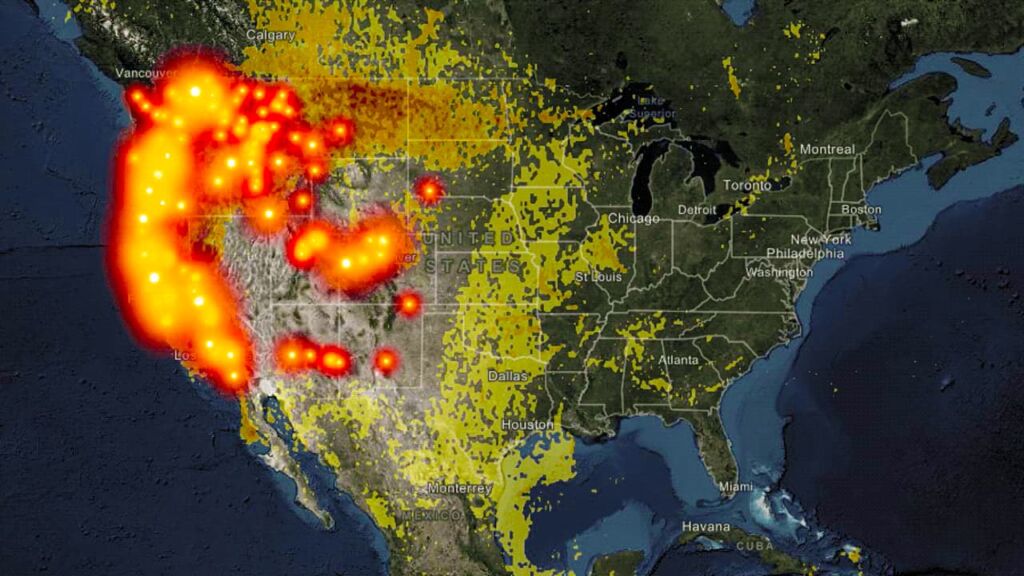

Water Supply and Quality

Water supplies should be tested prior to sprinkler installation to reduce the likelihood of contamination from water source bacteria. Additionally, the quality of the water should be understood to reduce corrosion that is induced from highly alkaline or acidic water supplies. NFPA 13 1999 Edition states in section 9-1.5 that “in areas with water supplies known to have contributed to microbiologically influenced corrosion (MIC) of sprinkler system piping, water supplies shall be tested and appropriately treated prior to filling or testing of metallic piping systems.”

NFPA 13 1999 Edition section 10-2.1 states “Fire service mains (from water supply to system riser) and lead-in connections to system risers shall be completely flushed before connection is made to sprinkler piping. Water supplies should be flushed to ensure that pipe scale and debris is not introduced into the sprinkler system at the time of installation. The flushing operation shall be continued for a sufficient time to ensure thorough cleaning.”

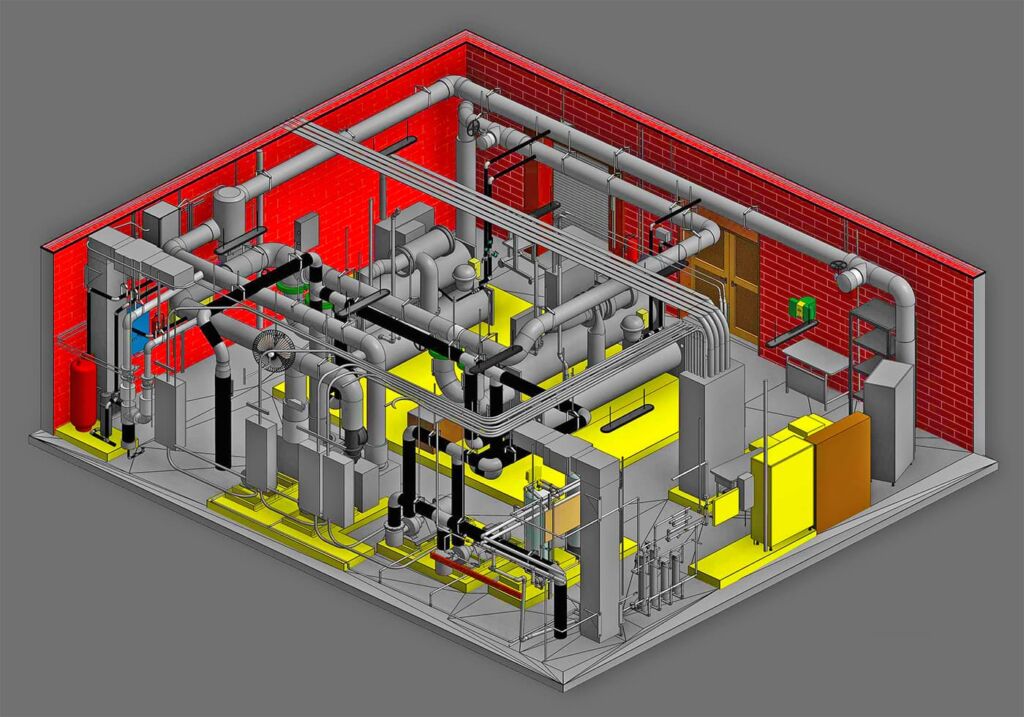

General Fire Pump Information

Information provided from Fire Protection System Inspection, Testing, and Maintenance Third Edition Carson and Klinker

A fire pump is designed to increase the water pressure. The pump intake discharge piping must be capable of flowing the required volume to which the pump will add the needed pressure for fire protection. The pump can be started manually, but is usually arranged to start automatically upon a drop in system pressure or the activation of a fire suppression system. Automatic starting requires a controller. Engines for operating the pump can be electric or diesel. Sizes range from 25 gallons per minute (gpm) to 5000 gpm.

Fire pumps are needed whenever pressure requirements of a fire protection system exceed the capabilities of the available water supply. Two types of pumps are typically used: centrifugal fire pumps, where water is available to supply the pump under pressure, such as a city supply; and vertical turbine pumps, where the available water supply is in a static state, such as a pond or reservoir.

Water enters the centrifugal pump through the suction inlet and passes to the center of an impeller. Rotation of the impeller drives the water by centrifugal force to the rim, where it discharges. One of the unique features of a centrifugal pump is that it takes advantage of the inlet water pressure and adds the pump pressure to it. For example, a centrifugal pump with a rated pressure of 100 psi at a certain flow having a 25 psi inlet pressure will produce that flow at 125 psi.

A vertical turbine pump usually has a right-angle gear drive with impellers connected to the pump head by a vertical shaft. As the pump operates, the water is passed from one impeller to the next impeller, gaining additional pressure at each subsequent impeller until the water passes through the pump outlet. The number of impellers indicates the number of stages for the pump.

Fire pumps are rated by their ability to pump a specific volume of water, usually measured in gallons per minute or liters per minute at a rated pump pressure and pump speed. The pump must be able to deliver 150% of this rated flow at 65% of its rated pressure. In addition, under no-flow conditions, the pressure must reach not more than 140% of the rated pressure (sometimes called the churn pressure). Most centrifugal pumps have a single impeller and are known as single-stage pumps. For high pressure demands, multistage pumps are needed.

Pumps are started and stopped by controllers. They start the pump when they sense the need for additional pressure or upon activation of a fire-extinguishing system. The controller can be arranged to stop the pump after reaching both a preset pressure and preset time. Pumps have timers so they will not continuously start and quickly stop, as would happen for a small leak or small flow. For the same reason, a small low-volume pump, known as a jockey pump, is often installed in the piping parallel to the fire pump to prevent cycling of the fire pump due to leaks.

Pumps are provided with circulation relief valves, to discharge water when the pump is being run with no water discharge. This valve is provided because, without it, the temperature of the water trapped in the pump casing would increase due to the centrifugal force created by the pump. The higher temperature could damage the fire pump.

Pumps taking suction from ponds or wet pits are provided with screens to make sure that the pump is not damaged by the introduction of solid materials into the pump. Foot valves are also provided on suction lines to assure that the pump maintains its “prime.” (Centrifugal pumps need the inlet piping and the pump casing full of water in order to start pumping. This water is called the “priming water” or “prime”).

Where variable-speed drivers are used (e.g., engine-driven pumps), pressure-relief valves are required. The relief valve will open should pressures exceed the system design pressure due to engine overspeed. Pressure-relief valves are also needed when the pump discharge pressure can exceed the rated pressure of any piping or valves on the discharge side of the pump.

Fire Pump Testing and Maintenance Frequency

Per NFPA 25, 2002

|

Device |

Activity |

Frequency |

|

Pump System |

||

|

Lubricate pump bearings |

Change |

Annually |

|

Check pump shaft end play |

Check |

Annually |

|

Check accuracy of pressure gauges and sensor |

Check |

Annually |

|

Check pump coupling alignment |

Check |

Annually |

|

Wet pit suction screens |

Check |

After each operation |

|

Mechanical Transmission |

||

|

Lubricate coupling |

Change |

Annually |

|

Lubricate right-angle gear drive |

Change |

Annually |

|

Electrical System |

||

|

Exercise isolating switch and circuit breaker |

Test |

Monthly |

|

Trip circuit breaker (if provided) |

Test |

Annually |

|

Operate manual starting means (electrical) |

Test |

Semi-annually |

|

Inspect and operate emergency manual start |

Test |

Annually |

|

Tighten electrical connections as necessary |

Check |

Annually |

|

Lubricate mechanical moving parts |

Check |

Annually |

|

Calibrate pressure switch settings |

Check |

Annually |

|

Grease motor bearings |

Change |

Annually |

|

Diesel Engine System |

||

|

Fuel |

||

|

Tank level |

Check |

Weekly |

|

Tank float switch |

Test |

Weekly |

|

Solenoids valve operation |

Test |

Weekly |

|

Strainer, filter, or dirt leg, or combination thereof |

Clean |

Quarterly |

|

Water and foreign material in tank |

Clean |

Annually |

|

Water in system |

Check/Clean |

Weekly |

|

Flexible hoses and connectors |

Visual Inspection |

Weekly |

|

Tank vents and overflow piping unobstructed |

Check |

Annually |

|

Piping |

Visual Inspection |

Annually |

|

Lubrication System |

||

|

Oil level |

Check |

Weekly |

|

Oil change |

Change |

Annually |

|

Oil filter |

Change |

Annually |

|

Lube oil heater |

Check |

Weekly |

|

Crankcase breather |

Change/Clean |

Quarterly |

|

Cooling System |

||

|

Level |

Check |

Weekly |

|

Antifreeze protection level |

Test |

Semi-annually |

|

Antifreeze |

Change |

Annually |

|

Adequate cooling water to heat exchanger |

Check |

Weekly |

|

Rod out heat exchanger |

Clean |

Annually |

|

Water pump(s) |

Visual Inspection |

Weekly |

|

Condition of flexible hoses and connections |

Check |

Weekly |

|

Jacket water heater |

Check |

Weekly |

|

Inspect duct work, clean louvers (combustion air) |

Check/Change |

Annually |

|

Water strainer |

Clean |

Quarterly |

|

Exhaust System |

||

|

Leakage |

Check |

Weekly |

|

Drain condensate trap |

Check |

Weekly |

|

Insulation and fire hazards |

Visual Inspection |

Quarterly |

|

Excessive back pressure |

Test |

Annually |

|

Exhaust system hangers and supports |

Visual Inspection |

Annually |

|

Flexible exhaust section |

Visual Inspection |

Semi-annually |

|

Battery System |

||

|

Electrolyte level |

Check |

Weekly |

|

Terminals clean and tight |

Check |

Quarterly |

|

Remove corrosion, case exterior clean and dry |

Change |

Monthly |

|

Specific gravity or state of charge |

Test |

Monthly |

|

Charger and charge rate |

Visual Inspection |

Monthly |

|

Equalize charge |

Check |

Monthly |

|

Electrical System |

||

|

General inspection |

Visual Inspection |

Weekly |

|

Tighten control and power wiring connections |

Check |

Annually |

|

Wire chafing where subject to movement |

Check |

Quarterly |

|

Operation of safeties and alarms |

Check/Test |

Semi-annually |

|

Boxes, panels, and cabinets |

Clean |

Semi-annually |

|

Circuit breakers or fuses |

Check |

Monthly |

|

Circuit breakers or fuses |

Change |

Biennially |

Backflow Prevention Devices

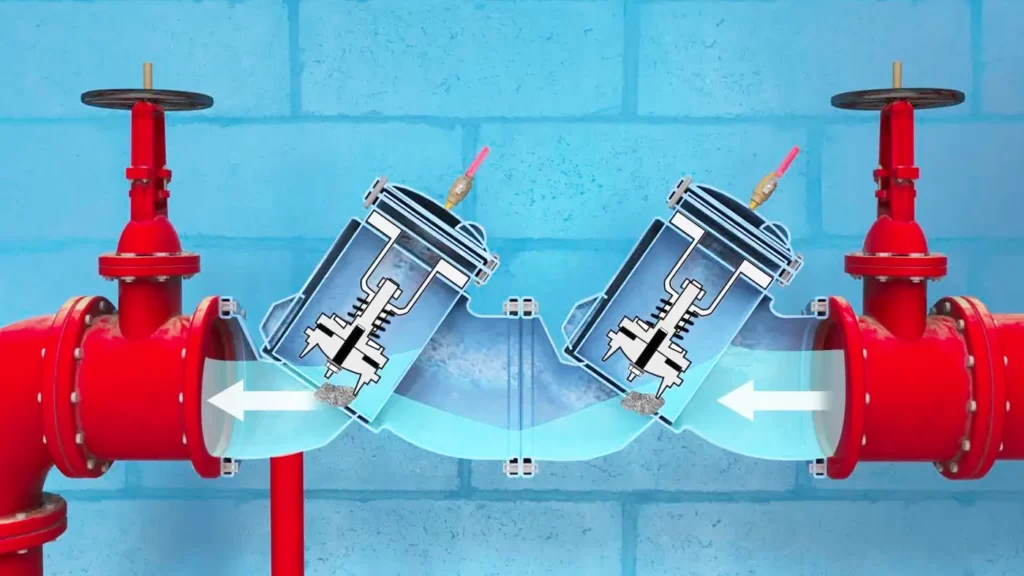

Double Check Valve Assembly (DC)

The double check valve assembly (DC) is composed of two single, independently acting check valves. The unit also has two tightly closing, resilient seated, shutoff valves located at each end of the device and four test cocks for the testing of the check valves.

Reduced Pressure Principal Assembly (RP)

Commonly referred to as an RP or RPP, this device consists of two independently acting check valves, together with an automatically operating pressure differential relief valve located between the two check valves. The first check valve reduces the supply pressure at a predetermined amount so that during normal flow, and at cessation of normal flow the pressure between the two check valves shall be lower than the supply pressure. If either check valve leaks, the relief valve will discharge to atmosphere. This will maintain the pressure in the zone between the two check valves lower than the supply pressure. The unit also has two, resilient seated, shutoff valves (one upstream and one downstream of the checks) and properly located test cocks for field testing.

Pressure Vacuum Breaker (PVB)

The pressure vacuum breaker (PVB) is a device that contains within a single body, a single loaded check valve and a loaded air opening valve which opens to admit air whenever the pressure within the body of the device approaches atmospheric.

The device has two tight closing, resilient seated, shut-off valves, and it is fitted with test cocks, appropriately placed, for testing the device.

Dual Check Valve (DuC)

The dual check (DuC) is a device which has two single, independent acting check valves in series. It does not have any test- cocks and is generally not field tested.

Dual Check with Atmospheric Port (DCAP)

This device has two independent acting check valves with a relief valve located between the checks. The device is not testable and should only be used for lower degrees of hazard.

Atmospheric Vacuum Breaker (AVB)

An atmospheric vacuum breaker (AVB) is a device which has a moving element inside, which during flow prevents water from spilling from the device and during cessation of flow, drops down to provide a vent opening. This device should not remain under pressure for long durations, and it cannot have any shutoff valve downstream of it.

Air Gap

An air gap is a physical separation between the free flowing discharge end of a potable pipe line and an open or non- pressure receiving vessel. To have an acceptable air gap, the end of the discharge pipe has to be at least twice the diameter of the pipe above the topmost rim of the receiving vessel, but in no case can this distance be less than one inch. This may seem to be the simplest, most effective and least expensive type of protection. However, the chance for future cross- connections the cost of additional pumps to pressurize the system often makes this an expensive protection system.

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.