Precision Fire Protection News

Understanding Tree, Looped, and Gridded Sprinkler Piping Arrangements

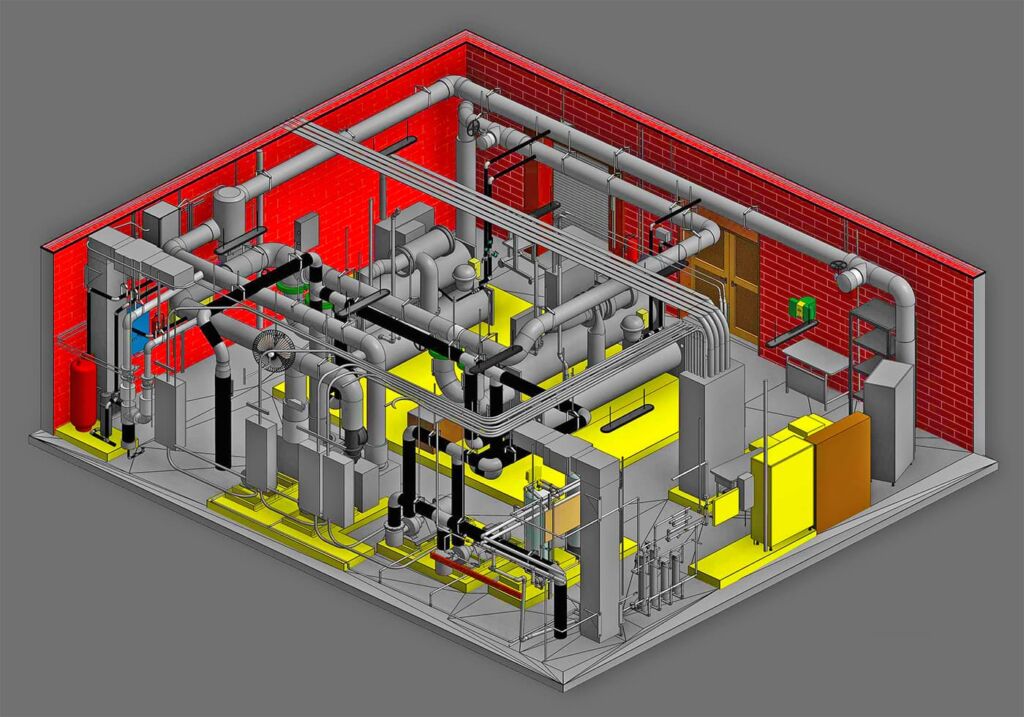

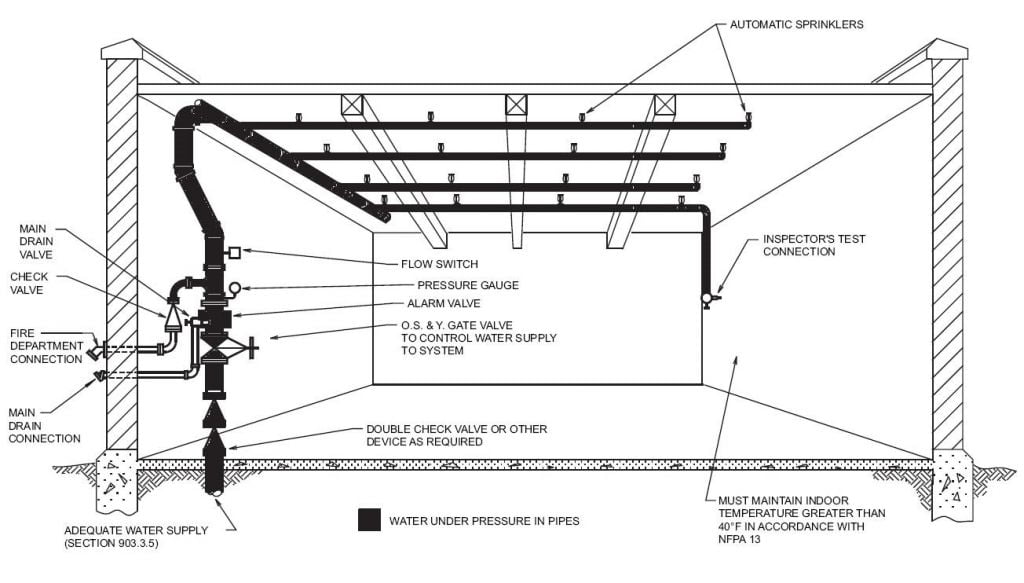

When designing an automatic fire sprinkler system there are a few options for how to arrange the piping. This decision affects the sprinkler system in a few different ways. It changes how the water flows from the water source to the sprinkler, how the system is calculated, and the components used. There are also limitations on when some of these arrangements can be used.

Understanding the benefits and drawbacks of each type of piping arrangement can help fire sprinkler designers, engineers, and installers choose the best arrangement for their given scenario. This blog will review the three most common piping arrangements used and provide a brief discussion of each.

Tree Sprinkler System

Sometimes called “dead-end systems,” tree systems were the very first type of sprinkler system designed back when NFPA 13, Standard for the Installation of Sprinkler Systems, was first developed. They are the most basic system of sprinkler pipe layout. In a tree system, the cross mains and the branch lines are only tied together at a single point, which means there is only one path for the water to flow to an operating sprinkler.

They are often used in small systems or systems with good water pressure. They are the least efficient type of sprinkler system with regards to friction loss in the piping, but they are the simplest to install. The hydraulic calculations associated with tree systems are the most basic and can be done by hand. Since there is less piping, the installation of this system might cost less than the other types of piping arrangements, but since water only has one path to the sprinkler, it requires greater flow and pressure. One additional consideration is that if you are designing using the pipe schedule method, the layout must be a tree-type layout, but this is uncommon.

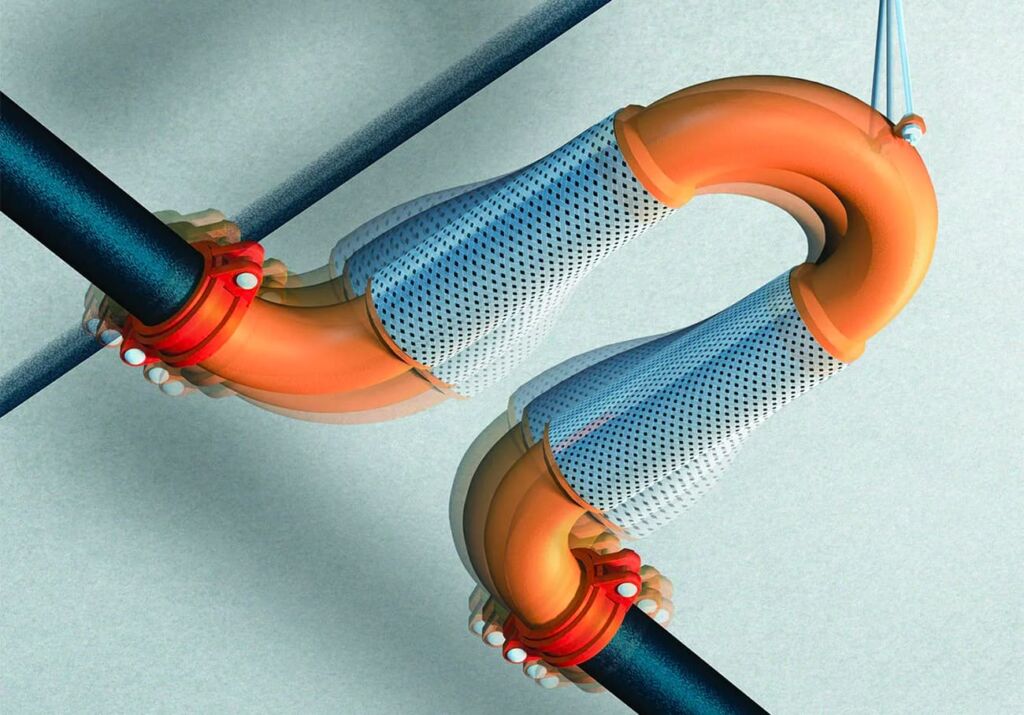

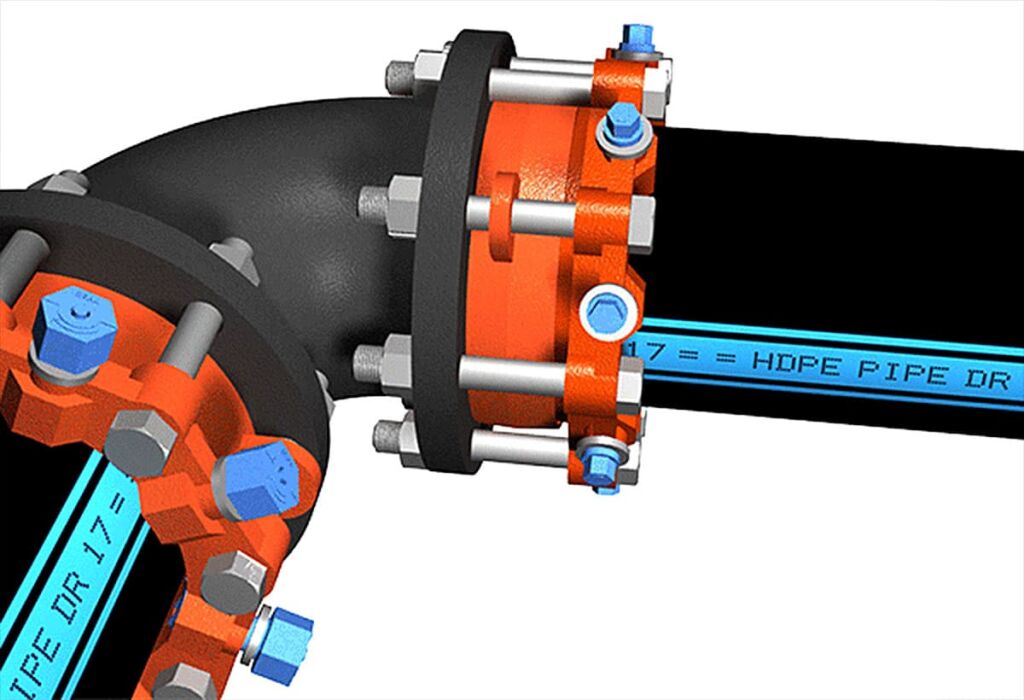

Looped Sprinkler System

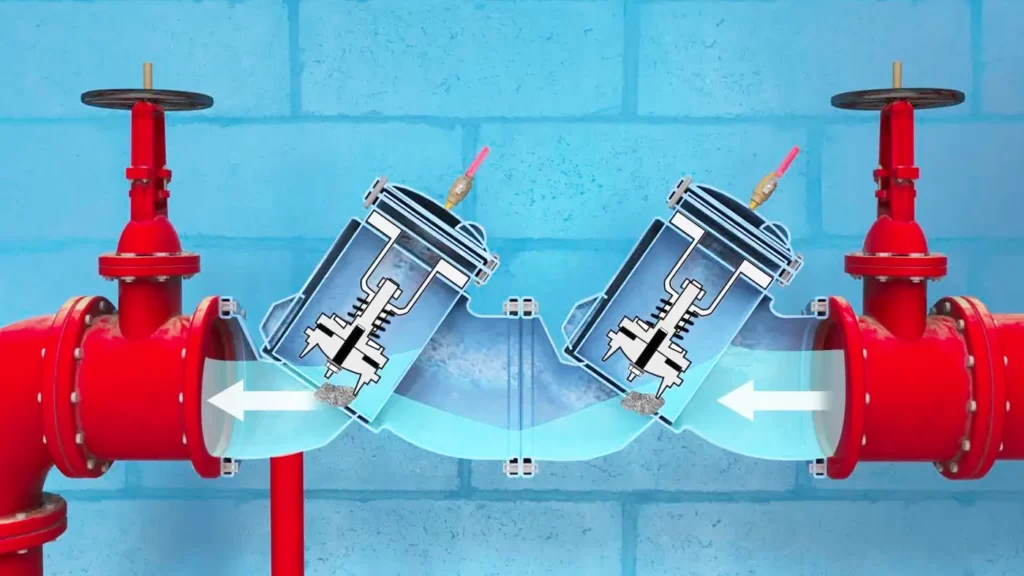

NFPA 13 defines a looped sprinkler system as “a sprinkler system in which multiple cross mains are tied together so as to provide more than one path for water to flow to an operating sprinkler and branch lines are not tied together.” In other words, the cross main pipe makes a loop, and the branch lines extend away from the loop. The big difference between a looped and gridded system is that in a looped system the branch lines lead to a dead end, while in a gridded system the branch lines are connected to the cross main on both ends. This means that for a looped system the water has two paths to travel until it hits the branch line, then it only has one path leading to an activated sprinkler.

A looped sprinkler system possesses better hydraulic characteristics than a tree system. While looped systems hydraulically perform better than tree systems, their hydraulic characteristics are not as good as those of a gridded system. The hydraulic calculations associated with a looped system are not as complicated as those for a gridded system but more complicated than those for a tree. Additionally, looped systems do not have the same limitations and design considerations as gridded systems have.

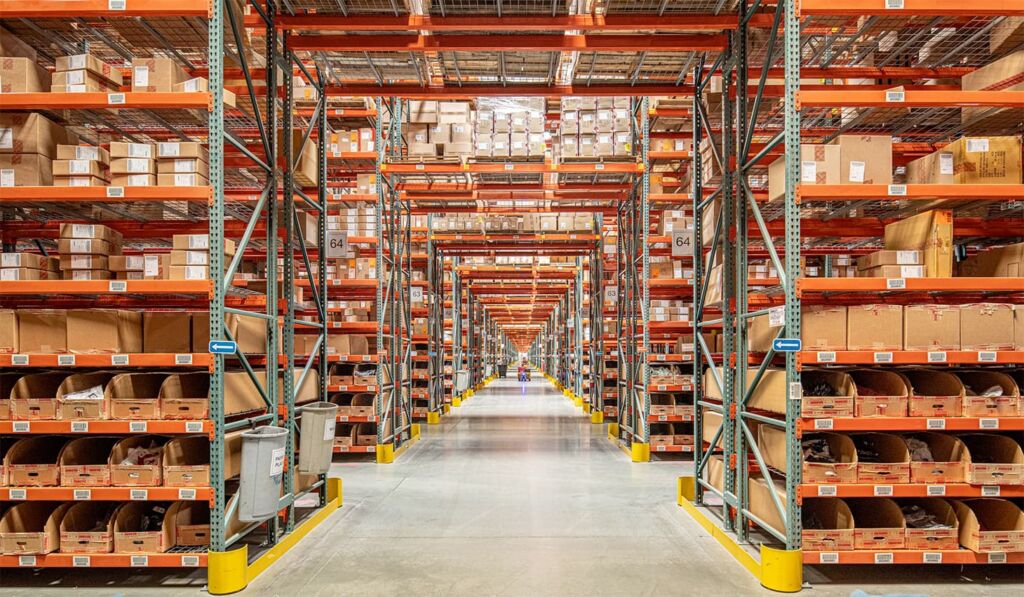

Gridded Sprinkler System

According to NFPA 13, a gridded sprinkler system is one in which “parallel cross mains are connected by multiple branch lines, causing an operating sprinkler to receive water from both ends of its branch line while other branch lines help transfer water between cross mains.”

Gridded sprinkler systems are designed to provide more than one flow path to the sprinklers on branch lines. This multiple-path design reduces the potential for pressure loss through the system piping compared with other system configurations. Due to the complex nature of the hydraulic calculations involved, the use of computer hydraulic programs is almost always necessary in evaluating the piping grid and determining the pressure requirements of gridded systems.

Although the gridded system possesses advantageous hydraulic characteristics, certain limitations and design conditions are associated with its use. For example, gridded systems are not permitted for dry pipe systems and double interlock preaction systems, because excessive amounts of air can remain trapped in the system piping, which significantly delays water from reaching the operating sprinklers. A single interlock or non-interlock preaction system is not subject to this requirement.

As part of the plans and calculations, gridded system designs must also include verification that the hydraulically most demanding combination of sprinklers was selected. These calculations are iterative and require a computer to solve.

Learn More

Many systems today can be a combination of tree, loop, and gridded configurations connected together to meet complex architectural features or to help with existing building expansions. Whether you’re using a tree, loop, or gridded system, the installation requirements for any sprinkler system can be found in NFPA 13, Standard for the Installation of Sprinkler Systems.

If you’re looking to learn more about sprinkler piping configurations and NFPA 13 sprinkler system design as a whole, I highly recommend checking out our online training offerings listed below.

SOURCE: NFPA

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.