Precision Fire Protection News

Top Five CPVC Cost Advantages for Architects

It falls to the Architect to design our future. To shape better, cleaner, safer lives for residents. As the Building Safety Bill continues to drive demand for better building and sustainability standards, Architects ask, what’s the true cost of this impressive future in construction?

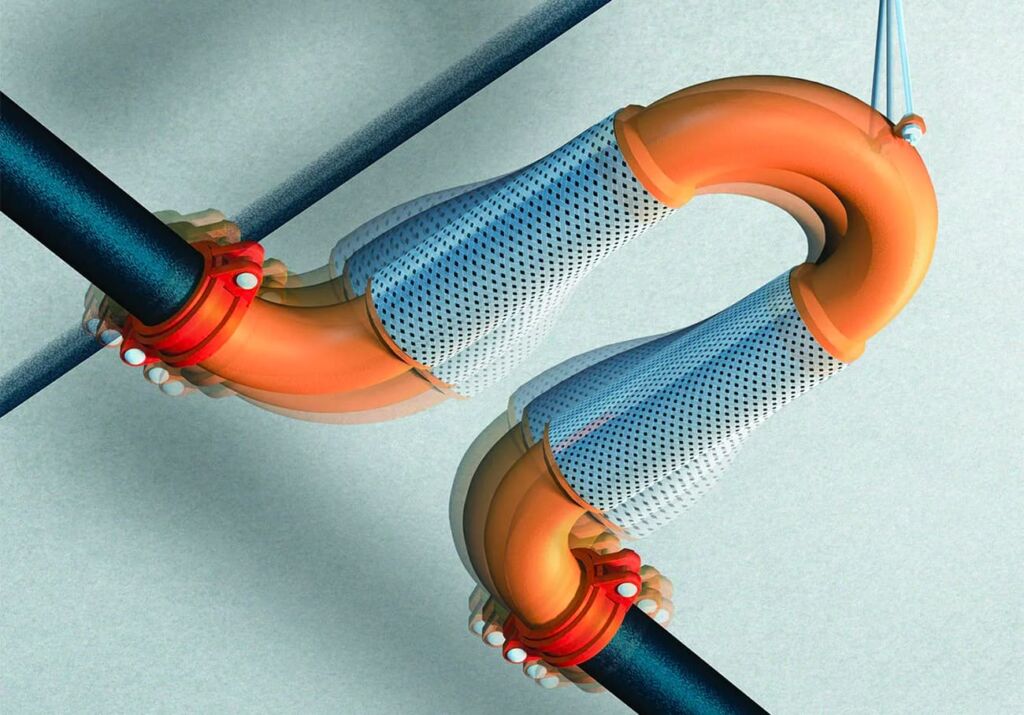

It’s not as expensive as you think. CPVC (chlorinated polyvinyl chloride) is at the forefront of stepping up building safety standards when it comes to fire. CPVC pipes and fittings are now the most specified non-metallic fire sprinkler system pipes and fittings in the world.

Read on for the top five ways you can step up your game in the future of construction and set the standard on your next project, without compromising on your budget.

Material Costs

In an independent cost comparison analysis between steel sprinkler systems and CPVC, direct material costs were calculated resulting in a 24.3% difference. The cost of fitting out a new dwelling with steel sprinklers was $18,409.05 more expensive.

Despite the major price differences between the two materials, architects around the world are saving money and experiencing all of these benefits at the same time:

- Exceptional flame and smoke characteristics

- Consistent performance in elevated temperatures

- Optimum hydraulic capability and pressure rating

- Superior corrosion resistance in all water conditions

- Like steel, does not support combustion

Specifying CPVC piping is an inexpensive but effective process, compared to steel.

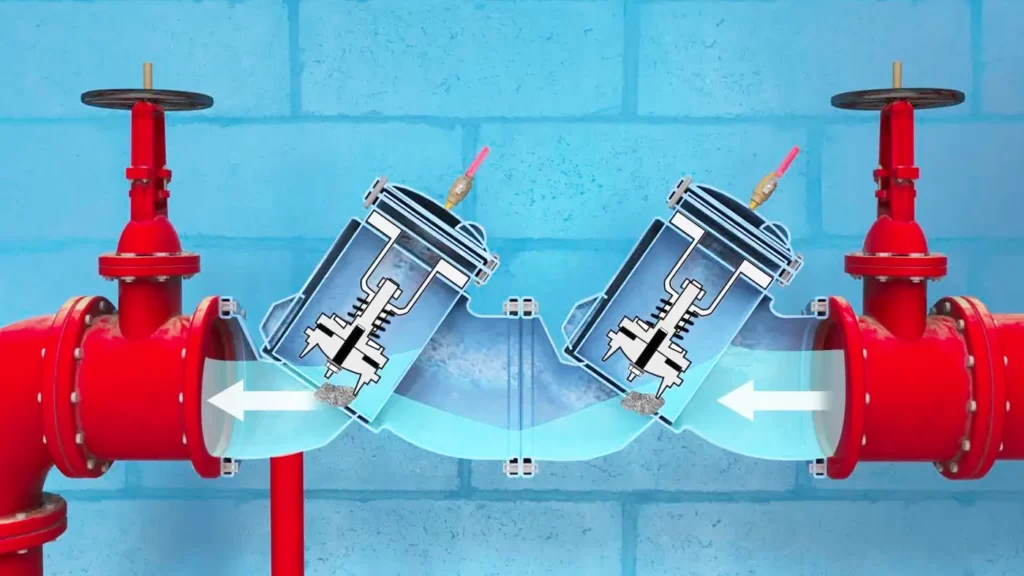

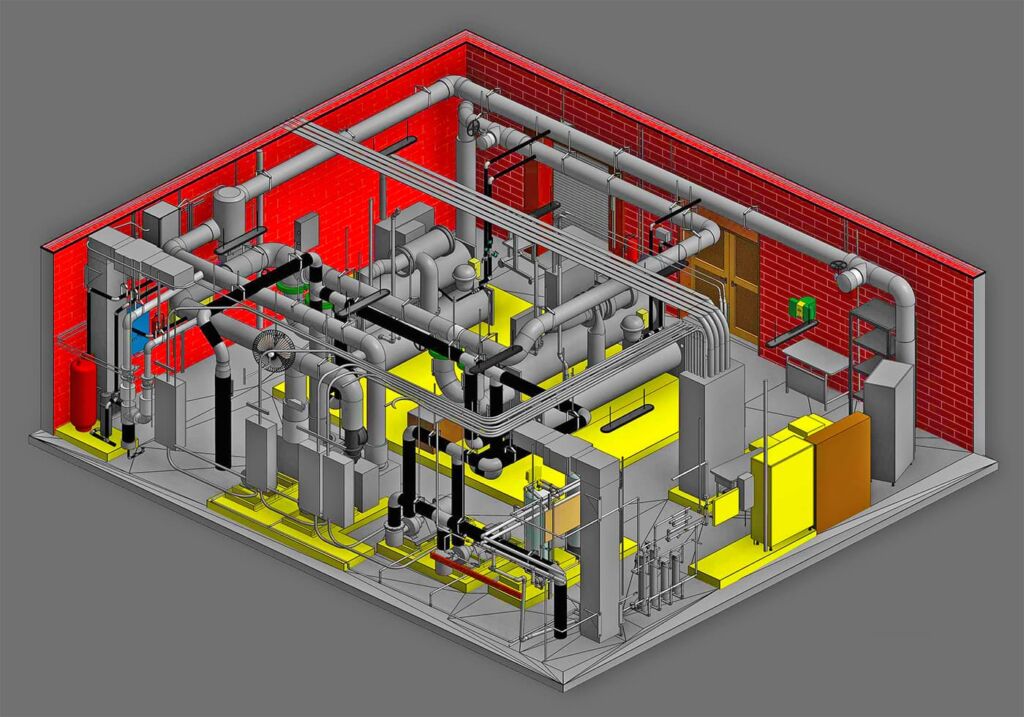

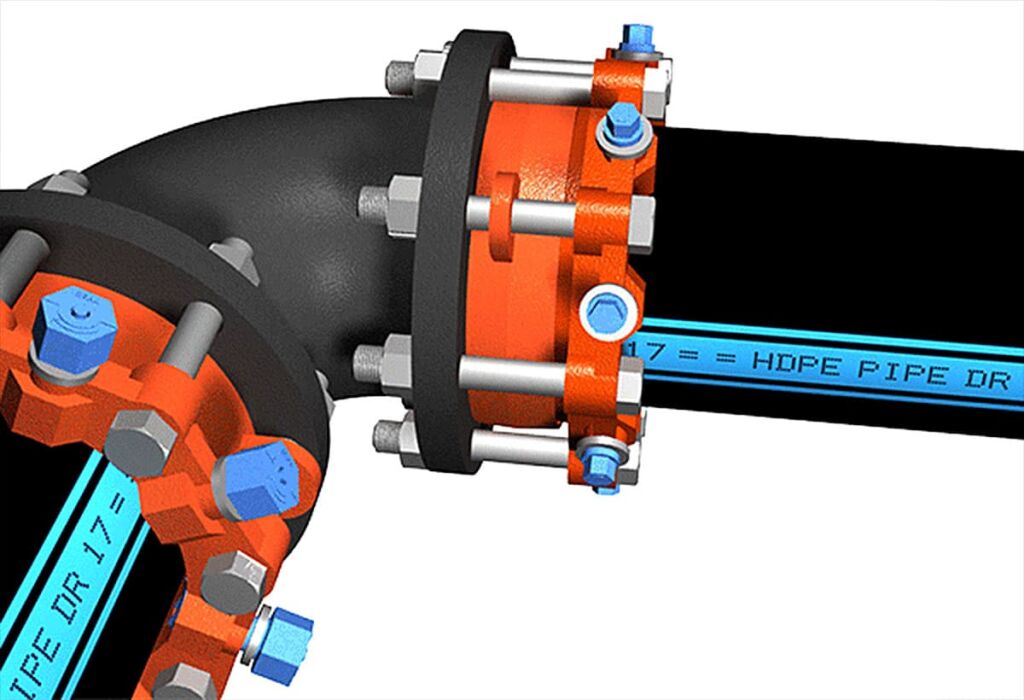

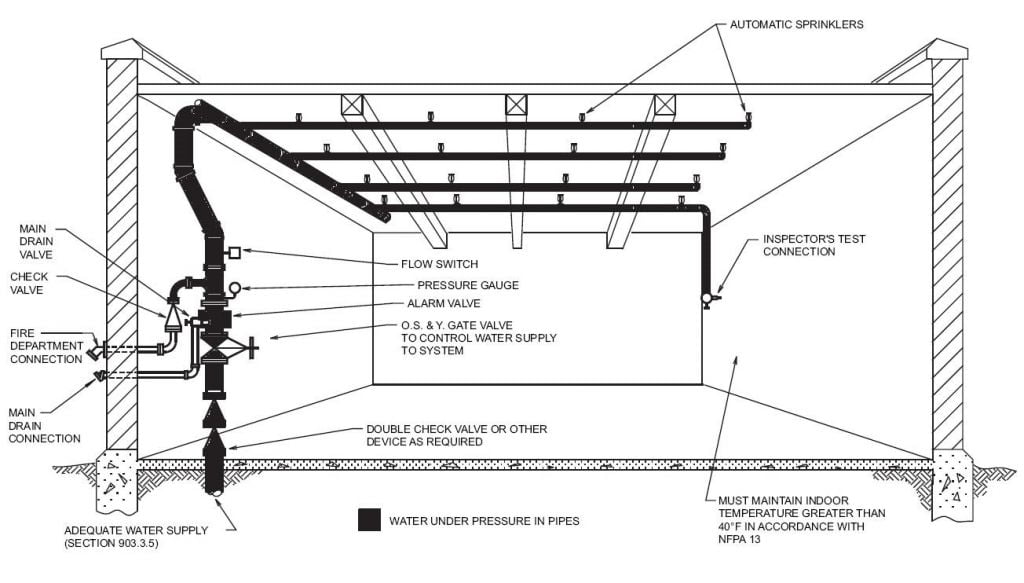

Installation

Use CPVC pipes and do more, with less. CPVC pipe requires an installation process which does not require heavy machinery like steel or copper pipes does, due to its lightweight material and innovative pipe and fitting fusion technology. Solvent cement welding requires only an individual to create permanent joints for long term performance.

In the cost comparison study, this process contributed towards a major difference in installation costs; using CPVC piping systems, resulted in a cost saving of over $25,000.

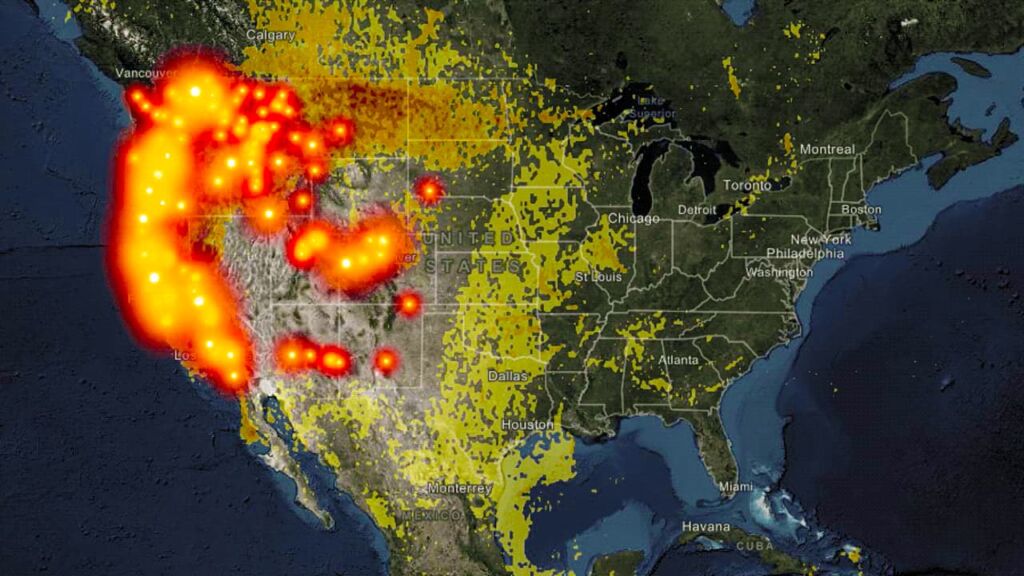

Sustainability

Levelling up on sustainability is everyone’s responsibility. However, Typically, Architects and system designers are the ones we rely on to set the trend on new buildings, introducing sustainable materials that have low impact on the environment.

The comparison study identified several additional advantages of installing CPVC pipe over steel:

- Requires less energy to process, manufacture and install

- Improved sustainability scores (cradle to cradle recyclability)

- Reduction of embodied carbon during production cycle

- Less energy wasted on repairs

These undoubtedly give designers the financial and environmental edge as we move towards a more sustainable future.

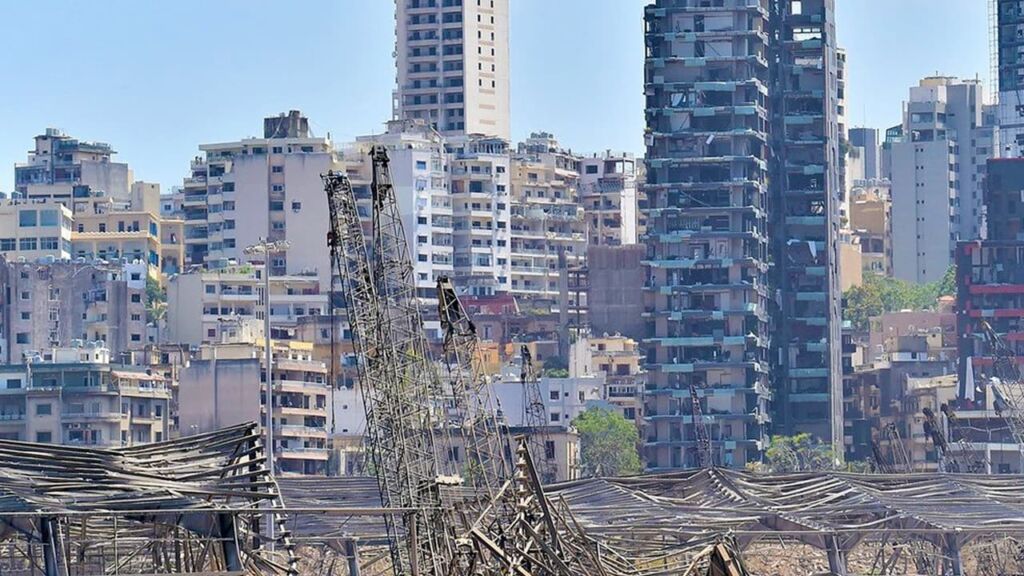

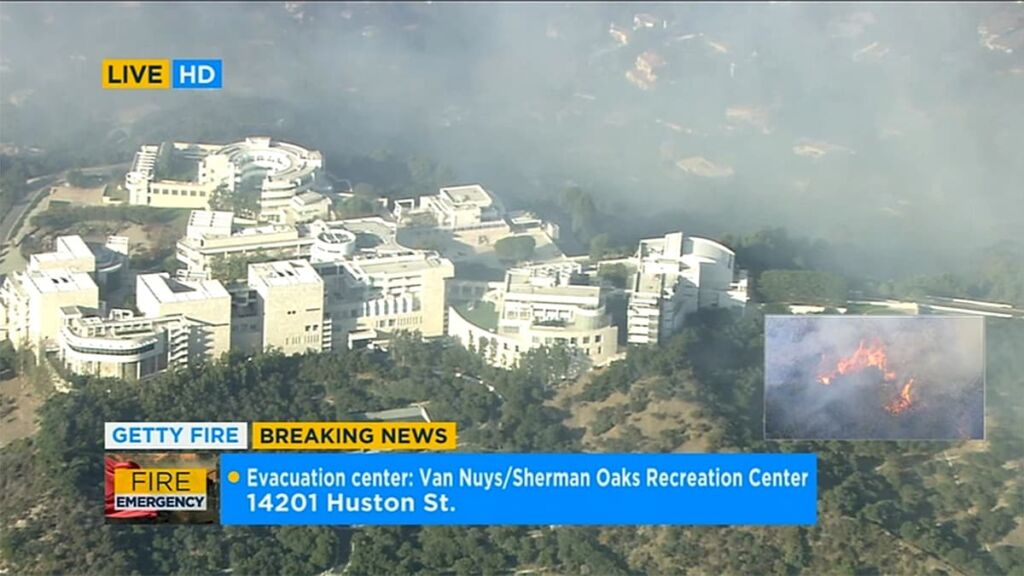

Retrofitting

Retrofit without relocation. Move faster on projects than ever before, with a safe, non-hazardous environment that enables installers to work on site while occupants continue life normally in the next room.

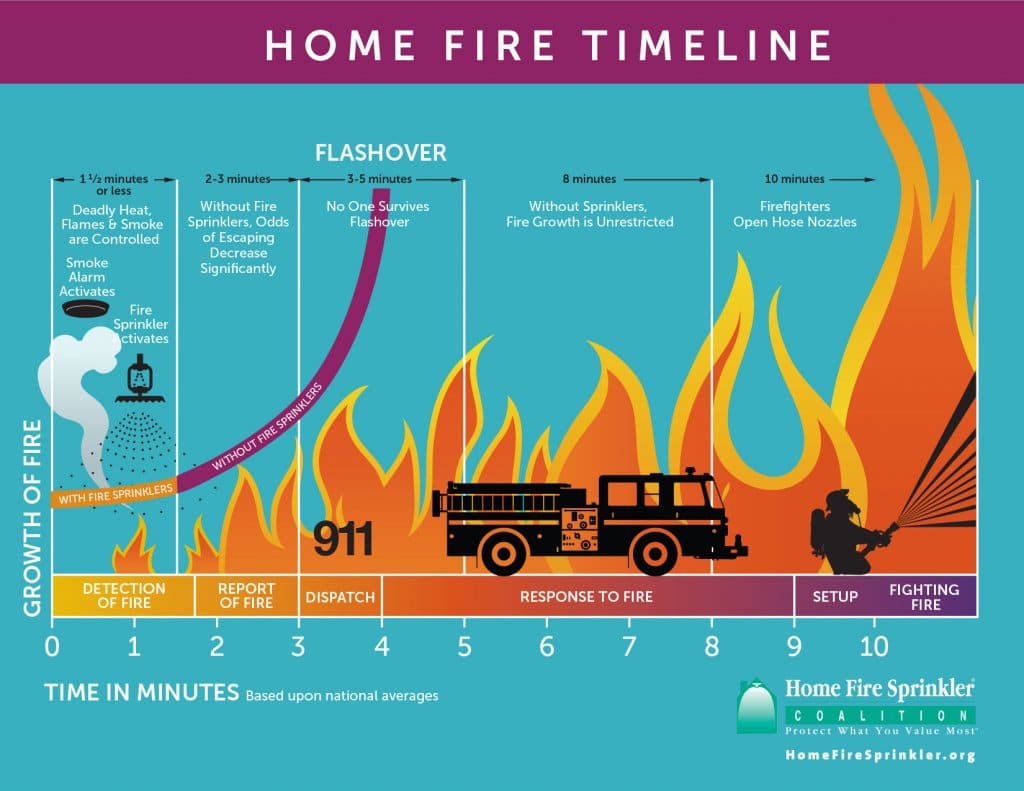

Retrofitting is a game changer in itself. As new fire sprinkler legislation takes a stronger hold, more and more buildings are being considered for sprinklers where previously there were none. It is vital that these buildings are equipped for safety in a timely manner.

Design

CPVC’s optimum hydraulic capability is going to be the key element in the Architect’s arsenal, particularly where retrofitting is concerned.

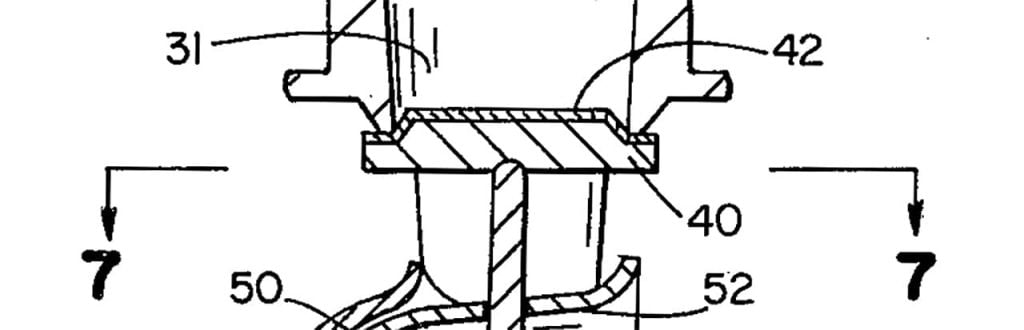

CPVC piping can be extruded in smaller sizes, allowing for smarter routing of sprinkler systems around new and old buildings, enabling sprinkler heads to reach more rooms and more people, improving the level of safety in the overall structure.

The material cost savings as detailed in the report means you’ll never have to choose between savings and safety. The future isn’t going to be about who has the biggest budget; it’s going to be about who is building smarter.

PEOPLE We Protect

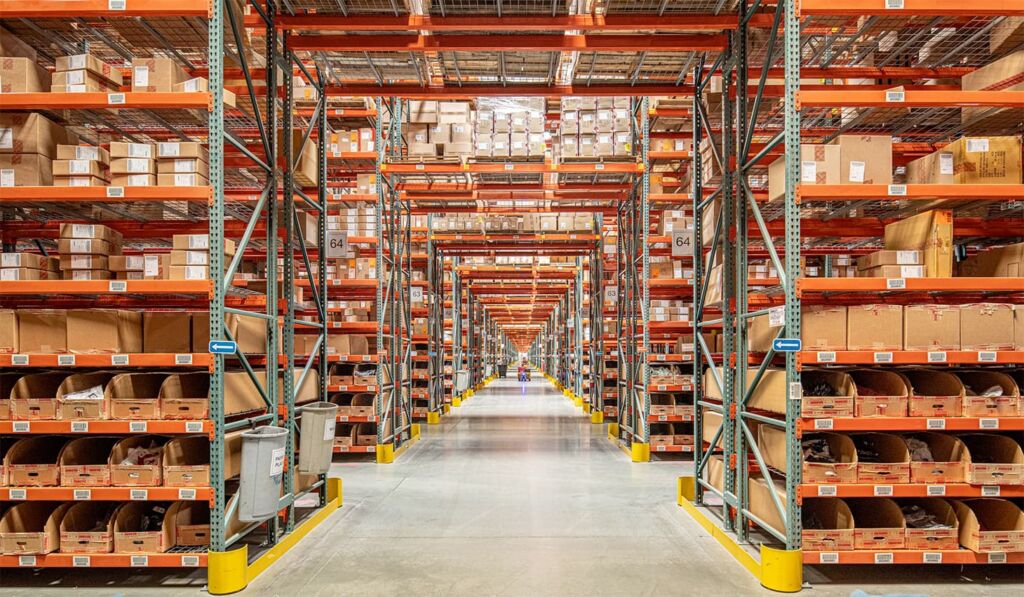

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.