Precision Fire Protection News

What Is a Floor Control Valve Assembly?

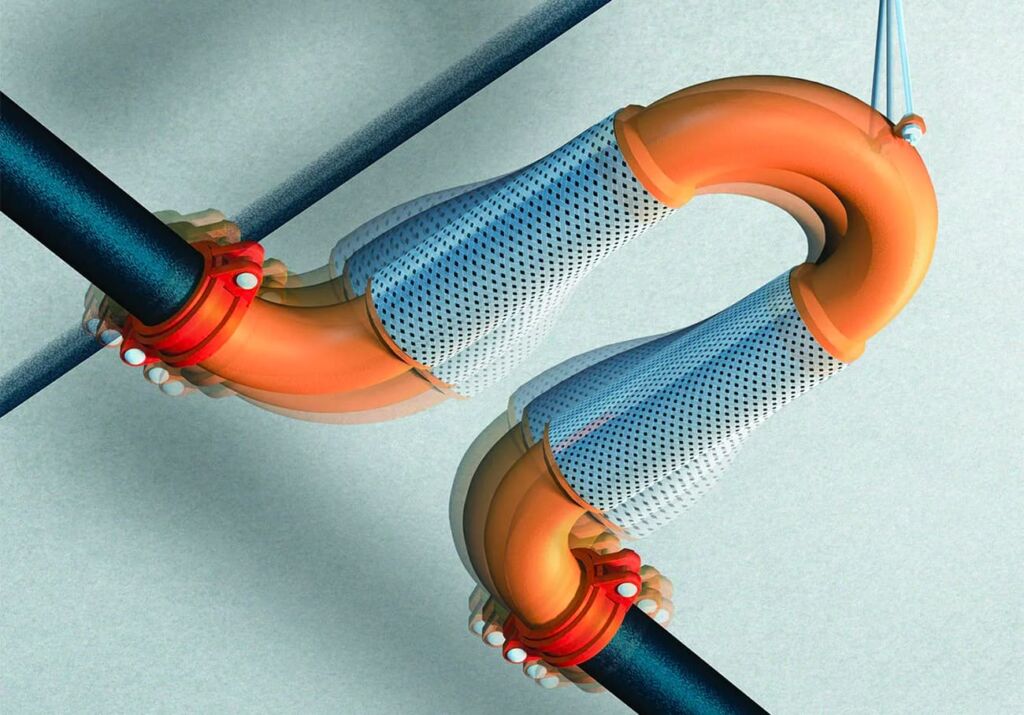

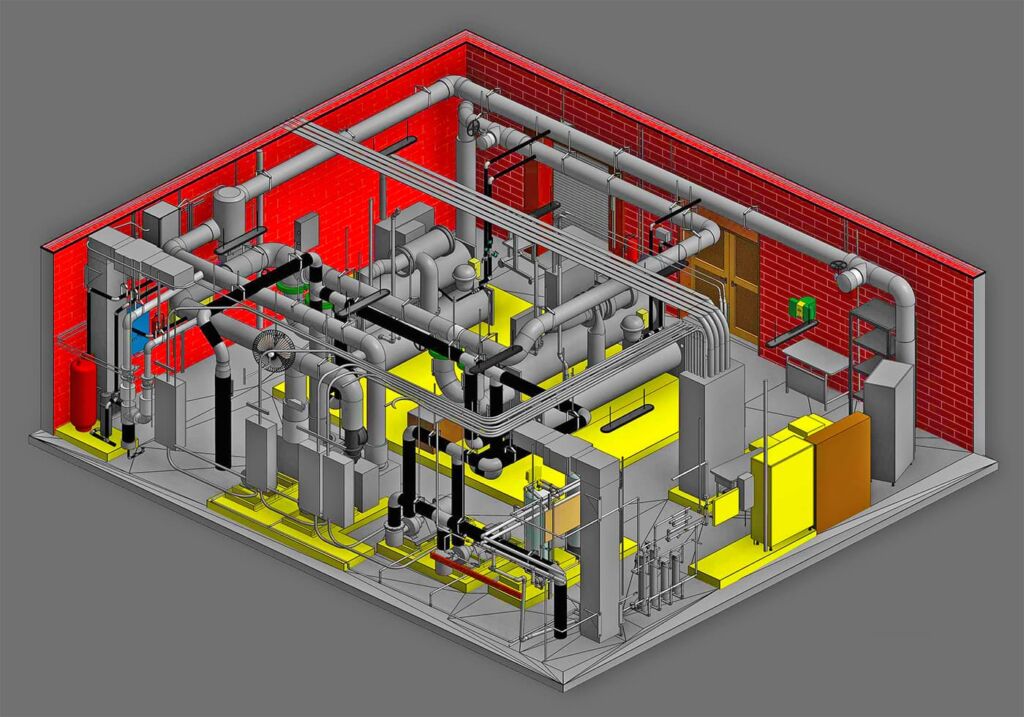

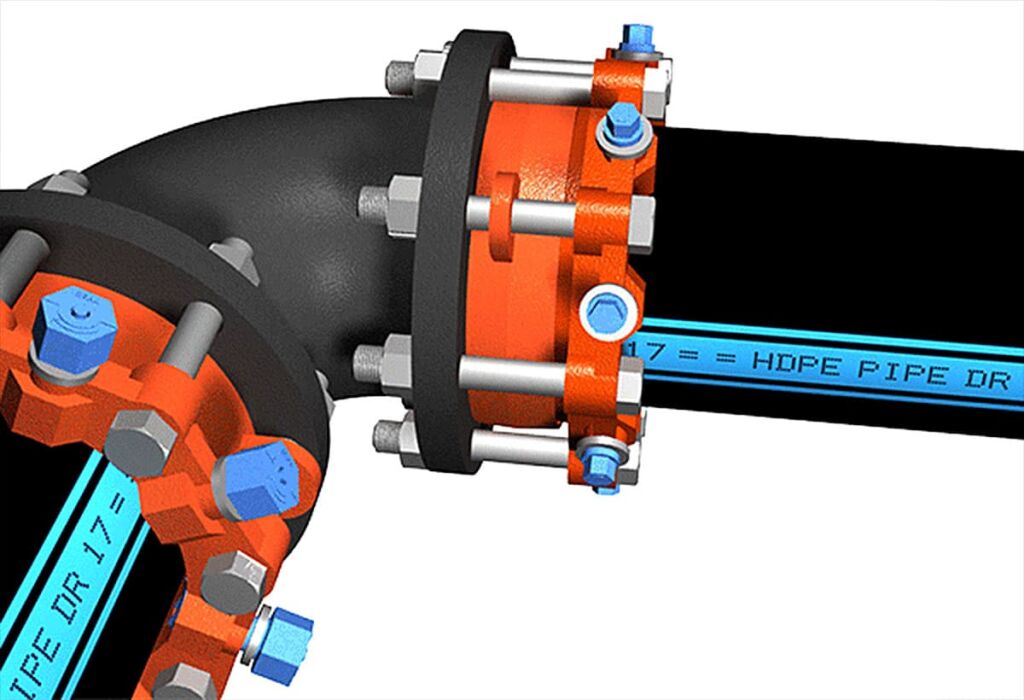

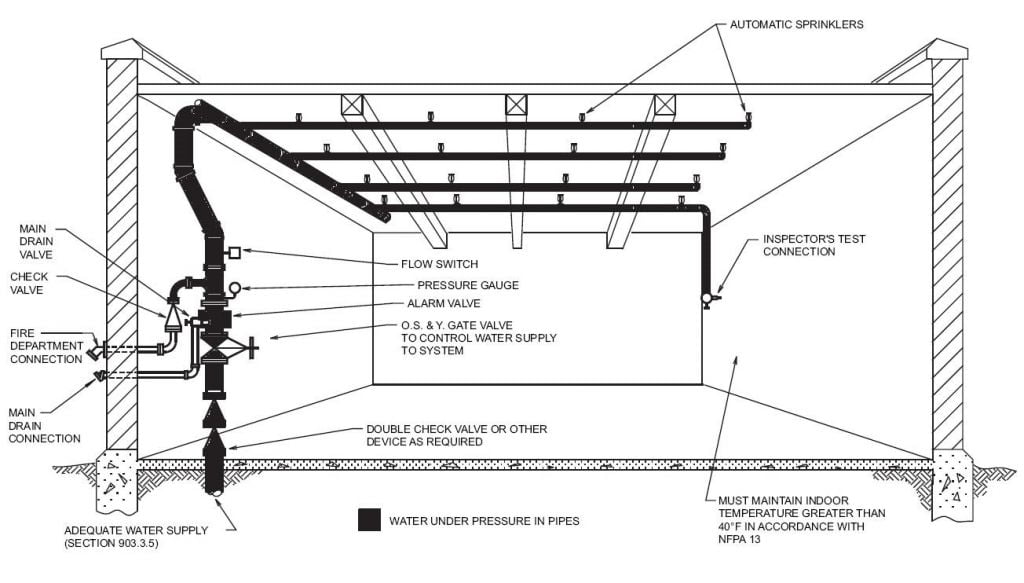

If you have an automatic sprinkler system in your building, then you may or may not be familiar with a floor control valve assembly (FCVA). The assembly consists of a control valve, a check valve, a pressure gauge, a main drain valve, and a flow switch. Although many manufacturers offer a pre-packaged product with all these components sold together, the assemblies are really just a series of components commonly found in sprinkler systems and do not need to be purchased as an assembly.

FCVAs essentially make every floor its own sprinkler system. They aren’t always required, but often are used to make maintenance or construction/rehabilitation work less disruptive and to allow responders to isolate a portion of the system should an activation or failure occur. FCVAs allow for certain portions of the system to be shut off, which allows the necessary work to be done in an area without compromising or taking the entire system offline. They may also aid in locating what floor water is flowing on.

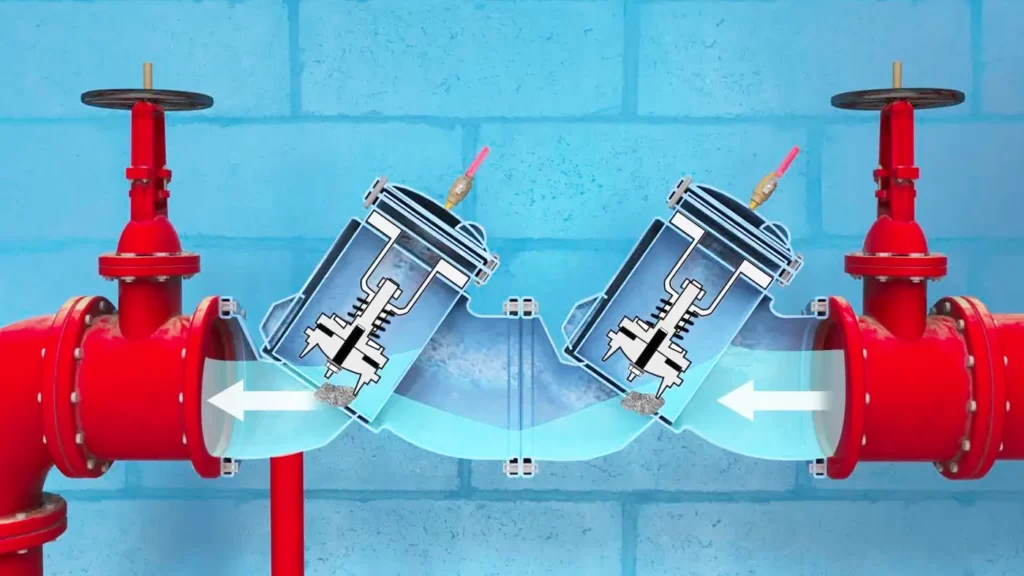

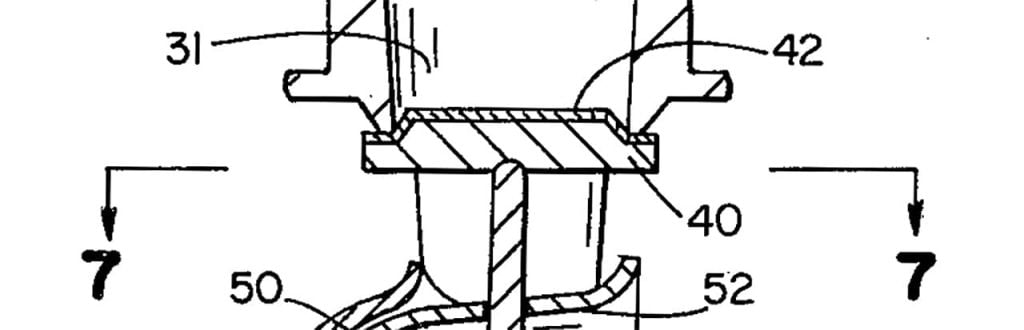

This image from NFPA LiNK® shows a floor control valve assembly.

Components of an FCVA

Control Valve

The control valve is typically either a butterfly valve or a gate valve that allows water to flow onto that particular floor. This valve is normally open. These valves must be supervised. Typically, they are either electrically monitored or locked. In some cases, electrical supervision is required (this blog provides more information about sprinkler supervision).

However, if maintenance needs to be done on a portion of the system, the floor control valve could be closed, the system on the floor drained, and work could be done without impacting the sprinkler protection in the remainder of the building.

Check Valve

A check valve is a one-way valve that allows water flow in only one direction. It ensures water is flowing in the correct direction. Although check valves serve a similar function as backflow preventers, they don’t offer the same level of protection. For example, check valves are not suitable for protecting drinking water sources. The check valve in the FCVA reduces nuisance trips of the water flow switch, which could otherwise occur because of normal water movement in the pipe.

Pressure Gauge

A pressure gauge displays the water pressure immediately inside the pipe the gauge is connected to. The pressure gauge is another way to ensure there aren’t any issues with the valves installed. The pressure gauge can be used in conjunction with the drain to verify that the check valve isn’t stuck, the control valve isn’t closed, or that there aren’t any leaks in the system.

Flow Switch

A flow switch is also known as a waterflow alarm device. It can be either electrical or mechanical. In either case, the main purpose of the flow switch is to trigger an alarm when water is flowing inside the pipe. It is often the connection point between a sprinkler system and a fire alarm system.

Main Drain Valve

The main drain valve is normally shut. In the case of the FCVA, the main drain valve can be opened to facilitate the draining of a particular floor while the remaining portions of the system remain functional.

In some cases, there will be a test and drain valve installed. The test and drain valve has three different positions: one that allows the valve to be fully closed, one that allows for testing of the flow switch by flowing water out of an orifice the size of a sprinkler, and a third position that allows that portion of the system to be fully drained. Flow switch testing is required by NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, and NFPA 72®, National Fire Alarm and Signaling Code®.

Where Are FCVAs Required?

NFPA 13, Standard for the Installation of Sprinkler Systems, requires FCVAs at each individual floor level for buildings over two stories in height. There are some exceptions to this. If the sprinklers on the top floor of a building are supplied by piping on the floor below, an FCVA is not required.

FCVAs are also not required where the total area of all floors combined does not exceed the system protection area limits outlined in NFPA 13. For light and ordinary hazard occupancies, that limit is 52,000 ft2 (4,830 m2). Lastly, FCVAs are not required in dry systems protecting parking garages. It is important to keep in mind that although FCVAs may not be required, it may be beneficial to still install them for maintenance purposes.

It is also important to note that other codes and standards may require an FCVA or something similar under certain conditions. For example, NFPA 101®, Life Safety Code®, requires a sprinkler control valve and a waterflow device on every floor for new high-rise buildings.

SOURCE: NFPA

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.