Precision Fire Protection News

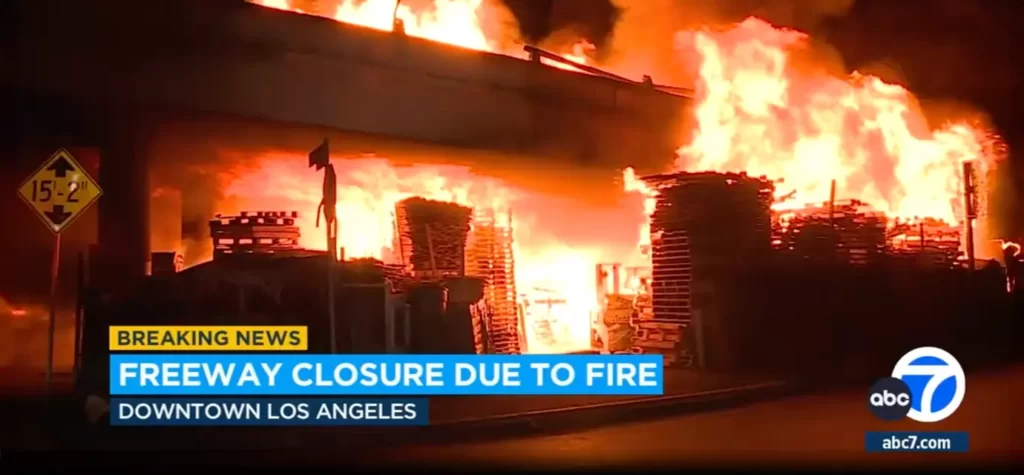

The Perfect Storm

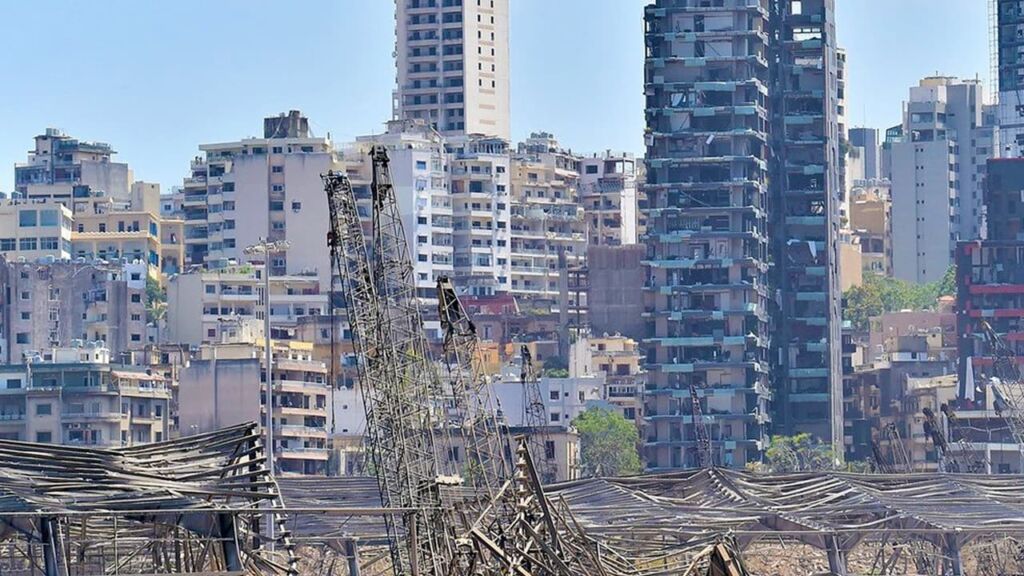

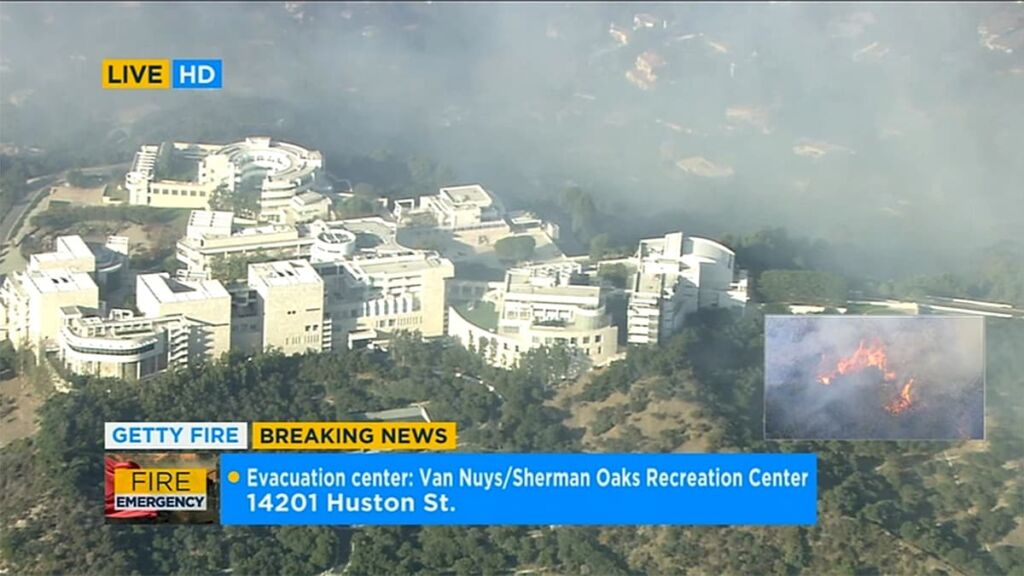

Sustainability was an essential part of the business ethos of Organic Valley, a Wisconsin-based dairy cooperative, down to the materials it used to construct its offices. And that’s where it ran into problems. $13 million in property damage and related losses.

BY BOB DUVAL

PHILIP STITTLEBURG, chief of the fire department in La Farge, Wisconsin, and chair of NFPA’s Board of Directors, contacted the association about a fire that had recently occurred in his town. The La Farge Fire Department responded to an automatic fire alarm at an office building in its fire district. When the first responding units arrived, they found a fire in a concealed space within the building. But what may have appeared at first glance as a routine fireground operation turned out to be anything but ordinary.

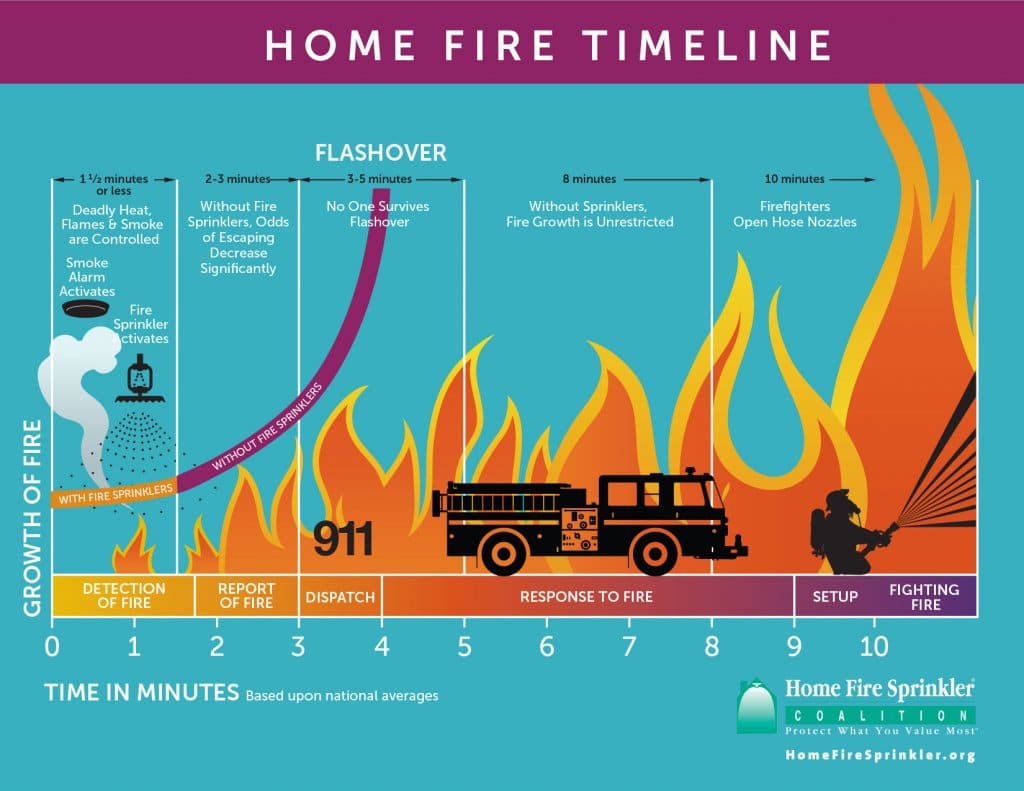

Firefighters would soon learn that the building’s concealed spaces were insulated with a recycled cotton-based denim material that was rapidly consumed by the growing fire, which eventually spread into an attic space constructed of lightweight wood trusses and equipped with automatic sprinklers. The building’s pitched roof structure was covered with arrays of photovoltaic (PV) panels that made vertical ventilation of the attic space by the firefighters nearly impossible.

Over the course of 18 hours, the officers and firefighters from La Farge, along with those from numerous surrounding departments, were faced with a growing array of challenges, including the location of the fire, the materials used in the building’s construction, the limitations of the town’s firefighting infrastructure, and more. The fire would eventually destroy a significant portion of building, resulting in an estimated $13 million inproperty damage and related losses.

After Chief Stittleburg contacted NFPA, and as more became known about the details and circumstances of the fire, the more it came to resemble a cautionary tale in the use of “green” or “sustainable” construction materials and what they can mean to firefighting efforts. The rooftop PV array, designed to reduce the building’s reliance on fossil fuels, also presented serious challenges to firefighters. In some respects, the La Farge incident became a kind of “perfect storm” fire, one that grouped a handful of challenges I’d seen elsewhere into a single event. NFPA accepted Chief Stittleburg’s invitation to visit La Farge and review the fire, and I was asked to travel to Wisconsin to see for myself how these factors combined to create an especially challenging fire situation—and to bring back the lessons learned at that fire.

The Fire

La Farge is a small community of roughly 750 residents, located approximately 42 miles (68 kilometers) southeast of La Crosse, in southern Wisconsin. The La Farge Fire Department (LFD) is an all-volunteer organization of 30 officers and members who operate eight pieces of apparatus out of one station located in the center of town, under the command of Chief Stittleburg. The predominant economic feature in town is the offices of Organic Valley, the world’s largest organic dairy cooperative, with worldwide sales of about $860 million in 2012. According to the co-op’s website, organicvalley.coop, the 45,000-square-foot (4,181-square-meter), three-story headquarters was built in 2004 for $5.9 million and houses about 400 employees.

At 4:29 p.m. on May 14, a fire alarm was received for the Organic Valley office building at One Organic Way. At 4:31 p.m. the dispatch center received a phone call from an LFD assistant chief, who was an employee at the facility, confirming a fire in the building. LFD apparatus arrived at 4:36 p.m. Chief Stittleburg arrived shortly thereafter and took command of the incident. Upon arrival, the chief observed smoke showing from the building’s west wing near a stairwell. A former member of the fire department who now worked for Organic Valley sought out the chief to inform him that smoke was visible from the ground floor up to the floor level on the second floor in the western portion of the building. Building occupants had safely exited.

The building consists of two wings connected by a central lobby area. As firefighters began to search for the seat of the fire along the western wing of the building, they noticed the fire was spreading vertically inside the wall, as well as horizontally within the wing’s southern wall and in the wing’s attic space. The interior spread was determined by the discoloration of the metal panels on the exterior of the building. The firefighters were told that the walls were insulated with cotton-fiber insulation consisting mainly of chopped denim fabric.

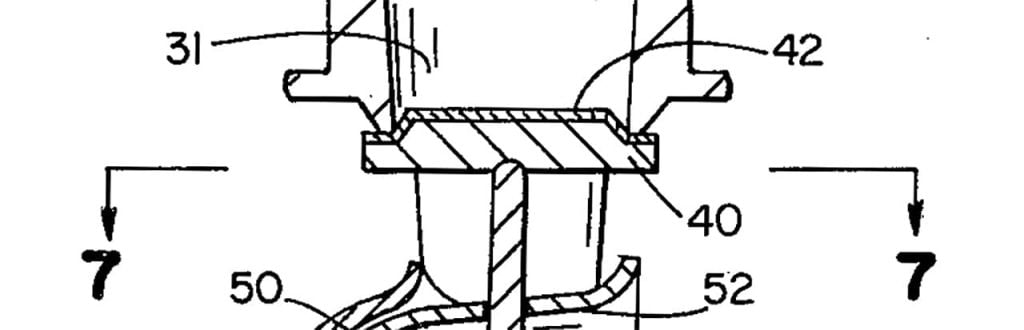

The floors of the structure were constructed of parallel wood trusses spaced 24 inches (61 centimeters) on center. The roof structure was constructed of lightweight wooden trusses consisting of 2 x 12-inch (5 x 30-centimeter), 2 x 8-inch (5 x 20-centimeter), and 2 x 6-inch (5 x 15-centimeter) members secured with metal gusset plates. The roof trusses were spaced 7 feet, 6 inches (2.3 meters) on center, and the gusset plates were spaced 3 feet 9 inches (1.1 meters) on center. The exterior roof surface consisted of standing-seam metal roof panels, which were fastened to the roof trusses. The roof system was designed to withstand the load posed by the PV panel installations.

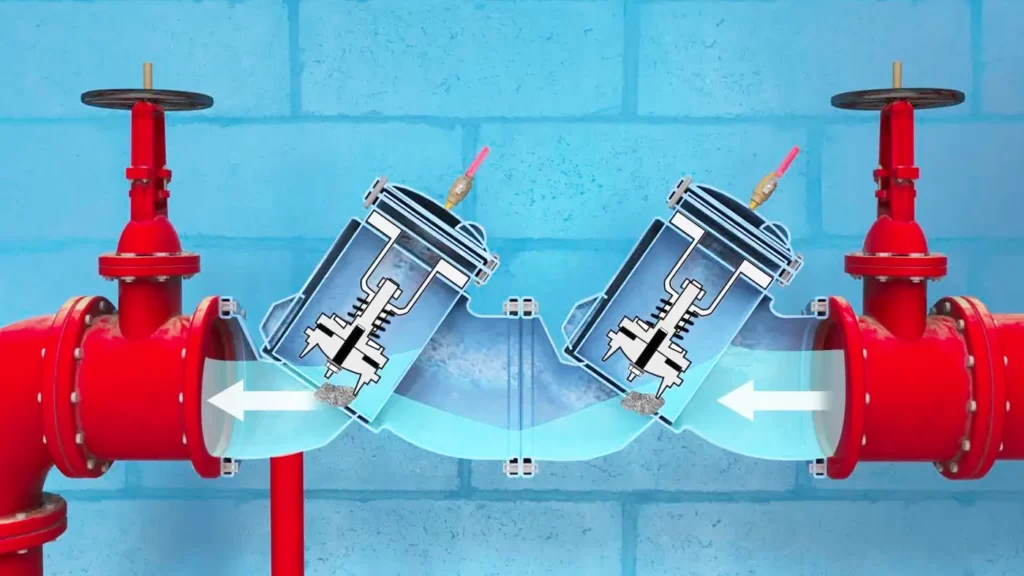

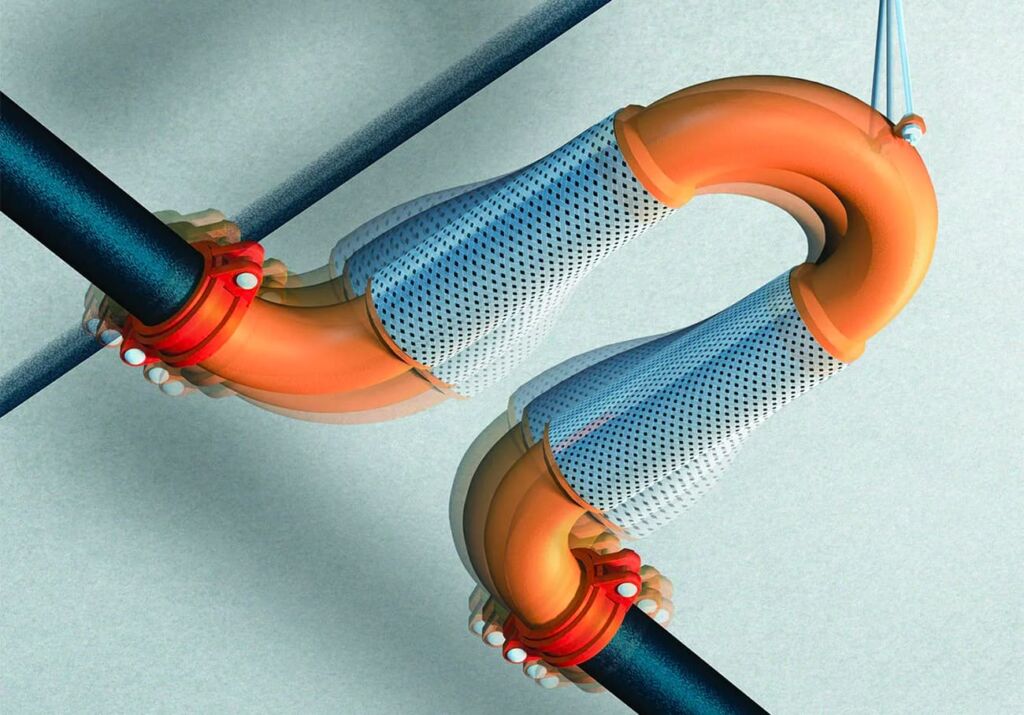

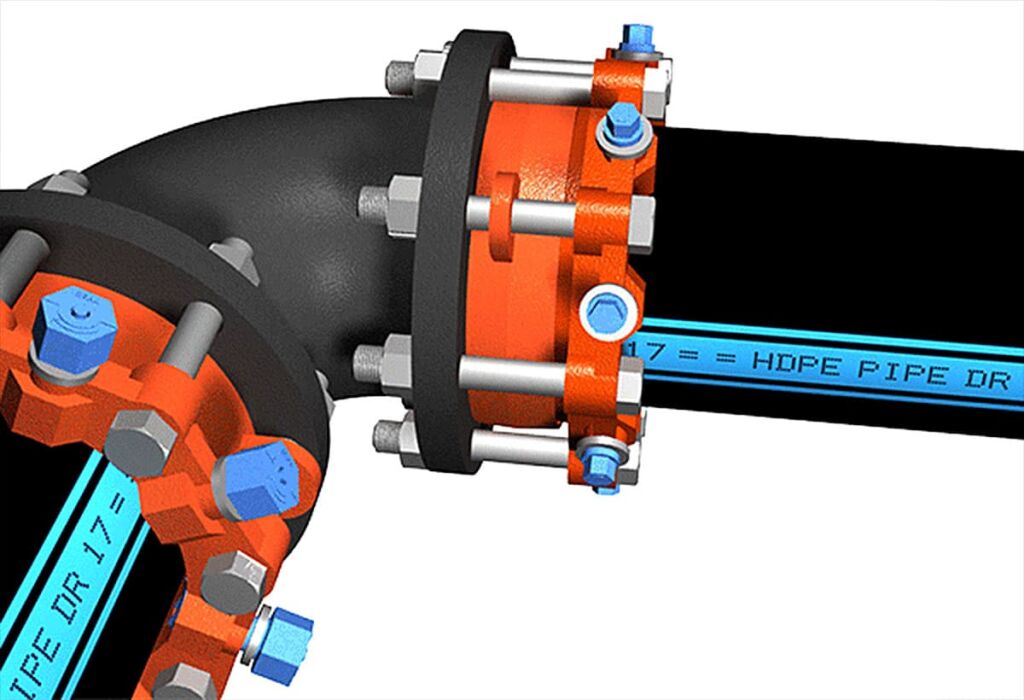

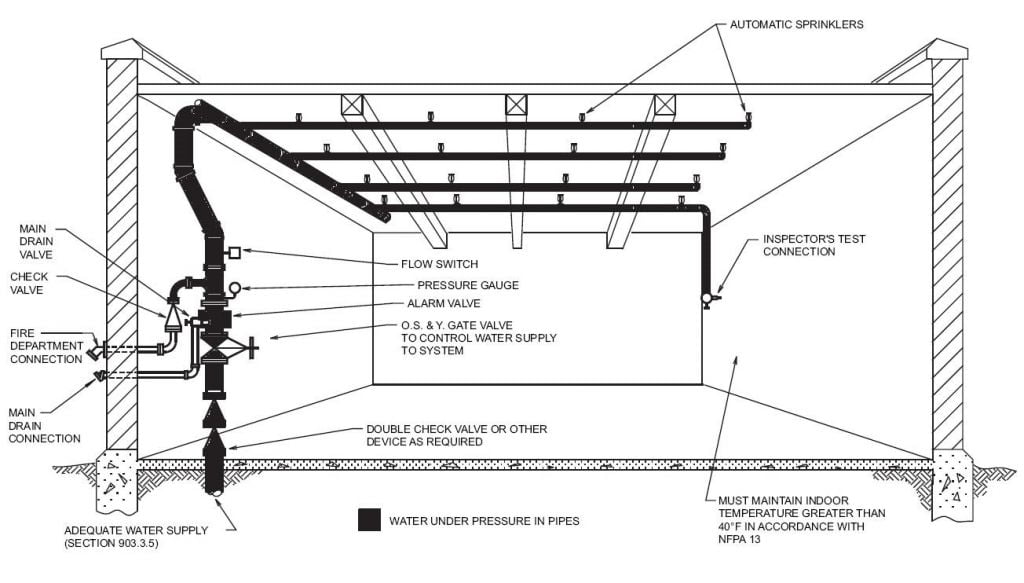

The building was equipped with automatic sprinkler protection throughout. The wet-pipe sprinkler systems within the three floors were designed at 0.10 gpm/square foot over 1,500 square feet. The dry-pipe system with attic was designed at 0.10 gpm/square foot over 1,950 square feet. Hose stream allowances of 250 gpm were included.

A second La Farge engine arrived, connected to the fire department connection for the sprinkler systems, and supported the systems throughout the incident. At 4:37 p.m., the incident commander requested an aerial apparatus, as well as additional firefighters from the nearby communities of Viloa and Viroqua.

Firefighters made access to the pitched roof of the west wing and were able to determine the extent of the PV arrays. The majority of the southern-facing surface of the roof was covered by 130 panels, making vertical fire ventilation operations nearly impossible. The PV system was rated at 70 kW; the day was partly cloudy with plenty of sun, so the panels would have generated their peak rating, or close. The incident commander ordered firefighters to stay off the roof due to the presence of the energized PV arrays and the unknown condition of the wood truss support system beneath. Vertical ventilation was not attempted.

Meanwhile, it was evident by the discoloration of the exterior metal panels that the fire continued to travel not only horizontally through the attic space, but also vertically within the walls of the wing. Firefighters accessed the attic space through a hatch in the east wing, but due to the lack of adequate ventilation they were unable to remain in the attic space and were pushed back by intense heat and smoke.

Firefighters continued to open concealed spaces in walls and ceilings, from the inside as well as the outside of the building, to seek out the fire travelling in these spaces. At 5:12 p.m. and again at 5:17 p.m., additional firefighters were requested from neighboring fire departments in Westby and Hillsboro. At 5:42 p.m., another request for an aerial unit was made to the fire department in Richland Center.

The local power company, La Farge Public Utility, was also requested to isolate the electric power within the complex to protect firefighters working on the blaze. During this operation, which took place around 6:30 p.m., a bucket truck from the power company was used to survey the condition of the PV panels on the roof of the west wing.

The roof structure had begun to show signs of weakening, and localized collapses in the space around the PV panels began to appear. Some of the PV arrays were beginning to deform and collapse into the attic space. A reading was taken to see if any electric current was being directed through the metal roof, and 50 volts of direct current — enough to shock and possibly kill a person, under certain circumstances — was found to be moving through the metal panels.

It was apparent that the PV arrays were still energized to some extent and that the collapsing roof was creating a path for electric current to pass through the metal roof structure, energizing the panels. This information was relayed to the incident commander, who passed it along to the firefighting forces. Had firefighters been operating on the roof at this time, there was a significant possibility of their suffering injury or death.

New problems arose. As firefighting efforts continued, the incident commander was notified at about 6:15 p.m. that there were problems with the water supply from the hydrant on site. The hydrant appeared to be functioning properly, but water pressure had dropped significantly since the arrival of fire department units. It was determined that a partial collapse of the roof trusses had compromised the dry-pipe sprinkler system in the attic space, resulting in water pouring into the building from broken pipes. The incident commander was also informed that at the current rate of consumption, the municipal water system, with a capacity of 101,000 gallons, would be drained in 45 minutes.

At 6:31 p.m., it was decided to establish a water supply shuttle operation using tanker trucks from the region to replace the municipal water system as the supply for firefighting. Six tankers were used to draw water from the nearby Kickapoo River and shuttle it back to the fire site, where it was transferred into a large portable storage tank; pumper trucks connected their hoses to the portable tank to continue their extinguishment efforts. The sprinkler systems in the second floor and attic spaces of both the east and west wings were shut down to stem the flow of water from the broken pipes.

Fire continued to devour the west wing of the building. Additional firefighting resources were requested at 8:08 p.m. from Yuba and at 8:14 p.m. from Coon Valley, and again at 12:17 a.m. from Stoddard and at 12:29 a.m. from Cashton Fire Departments. Suppression efforts eventually focused on the center area of the building, near the lobby, in an attempt to contain the fire to the west wing and prevent its spread to the lobby and a similar office wing on the east side.

With the partial collapse of the roof of the west wing, and the subsequent ventilation of fire, smoke, and gases, fire crews were eventually able to access the attic and extinguish the fire that was travelling through that space. Extinguishment efforts gained momentum on all three floors. It was determined that overhaul operations would continue into the night, and crews were rotated on three-hour shifts throughout the night and into the next day.

The incident was declared under control at 10 a.m. on May 15 — nearly 18 hours after the alarm was received from Organic Valley. The fire had involved 116 firefighters and emergency medical personnel, along with 31 pieces of apparatus, from 10 different communities.

Not by PV alone: An analysis of the Organic Valley fire

I traveled to La Farge in early June to investigate the Organic Valley fire. Even before I left for Wisconsin, I began listing some of the questions I hoped to answer while I was there. The role of the PV arrays was certainly near the top of my list, since they were featured prominently in the photographs of the fire and its aftermath. Once I was actually on the scene, though, and as I conducted interviews and learned more about the incident, the more it became apparent that the PV panels were just one aspect of the challenges faced by responders back in May.

I interviewed Chief Stittleburg and other members of the fire department, and I talked with investigators for the fire department and with Organic Valley’s insurance company. Everyone was concerned about the PV panels, since they kept firefighters off the roof and contributed to its collapse and the subsequent energizing of the metal roof panels. But they also had questions about the building’s lightweight construction elements; even though the roof was designed to carry the weight of the PV arrays, they had questions about the amount of time it took those lightweight elements to fail, leading to collapse.

Fire travel was also a big concern; the fire had reportedly started inside the end wall of the west wing and had moved vertically and horizontally inside the walls, beyond the reach of sprinklers, to eventually involve the entire wing. That pattern of travel raised questions about the combustibility of the cotton-denim insulation, as well as questions around the presence, and effectiveness, of fire blocking elements inside the walls. It was apparent that a variety of “green” or “sustainable” building methods, materials, and systems had contributed to a large, dangerous fire.

Lightweight Construction: The use of lightweight-type construction in all kinds of buildings today is common — the use of “engineered” lumber and metal structural members is marketed as more environmentally friendly (as well as less expensive) than dimensional lumber, and they can be found in many types of occupancies. Left unprotected, these lightweight elements can fail much faster than dimensional lumber when exposed to fire, increasing the risk of death or injury to firefighters and building occupants. The Organic Valley roof trusses were constructed in this lightweight method, and their eventual collapse caused the sprinkler piping in the attic to break, resulting in a large draw on the water supply during the fire suppression efforts.

The fire service has known about the potential hazards posed by engineered structural members and lightweight construction features for many years. Even so, firefighters need to be aware of the collapse potential when such structural members are involved in or exposed to fire. Knowledge of building construction features through pre-fire planning and building tours and inspections allows firefighters and fire officers to craft their strategy and tactics to allow for rapid fire spread and potential early collapse of lightweight constructed buildings.

Natural Fiber Insulation or Building Components: Valley prides itself in a commitment to environmental sustainability, and not just in the products it sells. Its website includes a detailed sustainability report noting the cooperative’s use of wind and solar-generated energy sources, and that 32 percent of the diesel fuel used by its local fleet is bio-based or straight vegetable oil, with a goal of 60 percent by 2015.

The same goes for its La Farge headquarters. The co-op’s website lists the building’s numerous “green” features, from energy-saving technologies to building materials low in volatile organic compounds, which can affect air quality. A variety of renewable and recycled materials were used in the Organic Valley building construction, including its insulation, which was manufactured from post-consumer recycled denim and treated with a non-toxic mold and mildew inhibitor.

While the cotton-fiber material provides an insulating value similar to that of conventional fiberglass insulations, which are noncombustible, it is also combustible under certain conditions. At Organic Valley, the cotton insulation played an important role in the fire’s travel through concealed wall and ceiling spaces. Product literature indicates that the insulation material has a “Class A fire rating” — more specifically, the literature cites a top “Class 1” rating for flame spread by the ASTM E84 test, and a top “Class 1” rating in the UL 723 smoke test, though these tests in fact only use ratings of Class A, B, or C. It is also possible that these tests may not be the right ones to apply to this particular material. The product literature does not specify whether the insulation material has been treated with flame retardant.

The use of natural fiber insulating materials is becoming more common as a means of meeting “green building” requirements. The fire service needs to be aware when this type of insulation is used within a building, because potential fire travel in vertical and horizontal spaces will have to be accounted for.

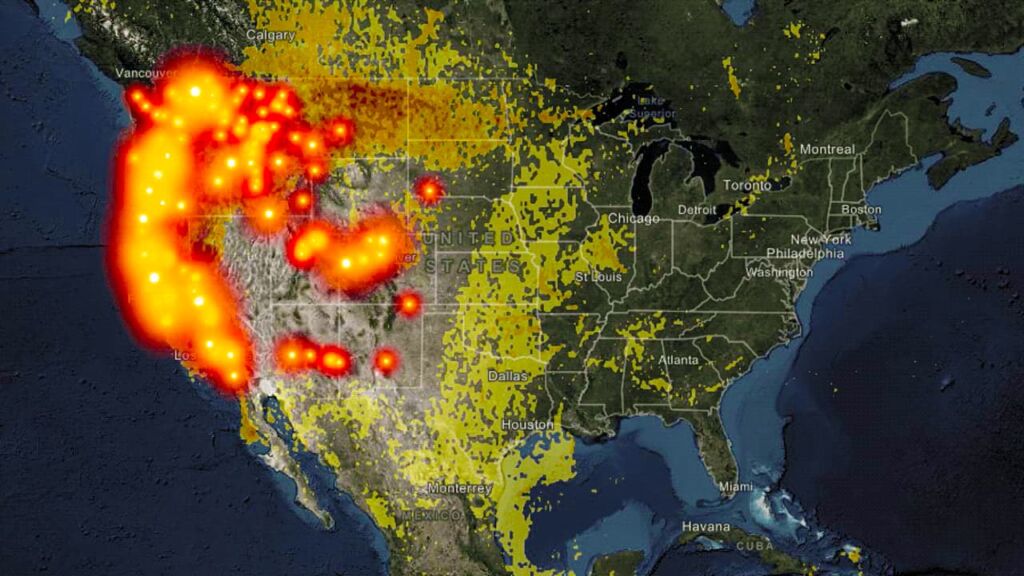

PV Systems: Relatively new in the building construction field, PV systems are today being installed in, on, and around many types of structures. Fire departments are encountering panel arrays on rooftops of all manner of occupancies, from single-family homes to major industrial buildings. The systems can be as small as a few panels to supplement a building’s electrical system, or as large as hundreds of panels designed to provide power for the facility as well as to sell it back to the local utility.

An important consideration, especially for firefighters, is that PV panels can continue to generate electrical power as long as they collect appreciable light. Interaction by firefighters around or below the panels — especially in the less-than-ideal conditions associated with firefighting, including smoke and hot gases — makes working near PV arrays a dangerous operation. Roof access amid PV panels can be difficult, with conduit and other PV system components being located throughout the roof area. PV panels cannot simply be “shut off” during firefighting operations, since they are always producing electrical current. They can be isolated from the building’s electrical system, however.

In the Organic Valley fire, the decision was made early not to commit firefighters to the roof of the building for ventilation operations. This turned out to be an accurate risk assessment when it was later discovered that the roof deck was being energized by the PV arrays contacting the metal roof panels, a result of the collapse of the building’s roof system. Both suppression and overhaul efforts were complicated by the fact that the PV system continued to generate electricity. In the Organic Valley fire, as in most fires where PV arrays are involved, many areas of the structure could not be accessed by firefighters until the panels were either safely removed or isolated.

Water Supply and Sprinkler Performance: Farge is typical in that the public water supply is designed and arranged to support the needs of the town center on a normal day for domestic, light industrial, and commercial usage. A major fire event, using several thousand gallons of water in a short period of time and utilizing only the domestic water system, can often tax such a system to the point of failure. In the Organic Valley fire, the collapse of the roof and the subsequent rupture of a sprinkler main in the attic resulted in a rapid draining of the community’s water system holding tanks.

Fire departments need to consider such scenarios when faced with development in their communities. The fire service needs to know if the public water supply will be overtaxed by a major incident, and it needs to plan for alternatives such as the tanker operations that were used during the Organic Valley fire, or for the use of large-diameter hose to move water from a static source, such as a lake or pond or fire boat, to a fire.

|

Investigation of the Organic Valley fire confirmed that the building’s sprinkler system worked as intended, but that its effectiveness was compromised by the circumstances of the fire. Sprinklers operated within the building, including the attic, but due to the vertical and horizontal fire travel through the concealed spaces of the building’s west wing, not all of the suppression capabilities of the sprinklers were realized. Observers said sprinklers were able to slow the fire, but were unable to reach the seat of the fire for effective extinguishment.

The challenges encountered in the Organic Valley fire underscore some of the broader fire safety issues presented by sustainable building practices. Green building construction techniques are gaining momentum around the world as building codes require increased energy savings and as credits are given to buildings and developments using energy saving methods, building materials, and equipment. As more of these efforts are undertaken, it is important to recognize that the stakeholders extend far beyond building occupants and firefighters; they include building designers, systems designers and installers, inspectors, code developers, and more. All of these stakeholders must participate in the ongoing discussions on how best to address questions of fire safety in structures utilizing these new and emerging technologies.

NFPA is already playing an important role in leading those discussions. The 2014 National Electrical Code®, for example, has incorporated changes to address firefighter safety concerns regarding PV panels, and the 2012 edition of NFPA 1, Fire Code™, includes information on a range of PV issues in Section 11.12. Additionally, the Fire Protection Research Foundation is involved in research efforts addressing different aspects of green building safety. This work, as well as that underway at Underwriters Laboratories and elsewhere, promises to provide an analytical foundation for some of the problems associated with sustainable construction.

Firefighters have provided anecdotal evidence of these problems for years, and organizations like the National Association of State Fire Marshals have been instrumental in driving these issues to the forefront of fire safety concerns. New quantifiable information that complements the observations of the fire service promises to be an important part of the codes and standards development in this area for many years to come.

Bob Duval is New England regional director and senior fire investigator for NFPA.

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

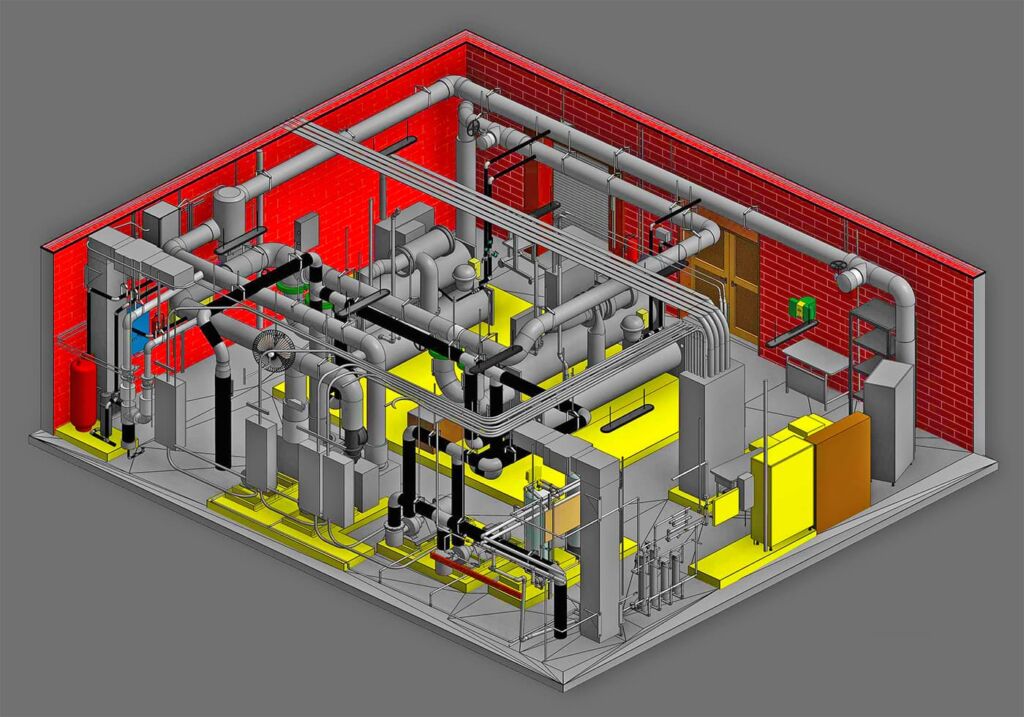

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.