Precision Fire Protection News

Elevator and Machine Room Fire Safety

When are Sprinklers Required in Elevator Shafts and Machine Rooms

Elevators are found in almost all new buildings that are greater than one story. While they certainly provide a convenient and accessible means for traveling up and down through a building they also create vertical openings in a building, increasing the potential for the spread of fire and smoke. There are many fire and life safety code provisions that mitigate this risk and permit elevators to be used without increasing the risk to occupants. This blog will focus on one aspect of this fire protection; whether or not fire sprinklers are required.

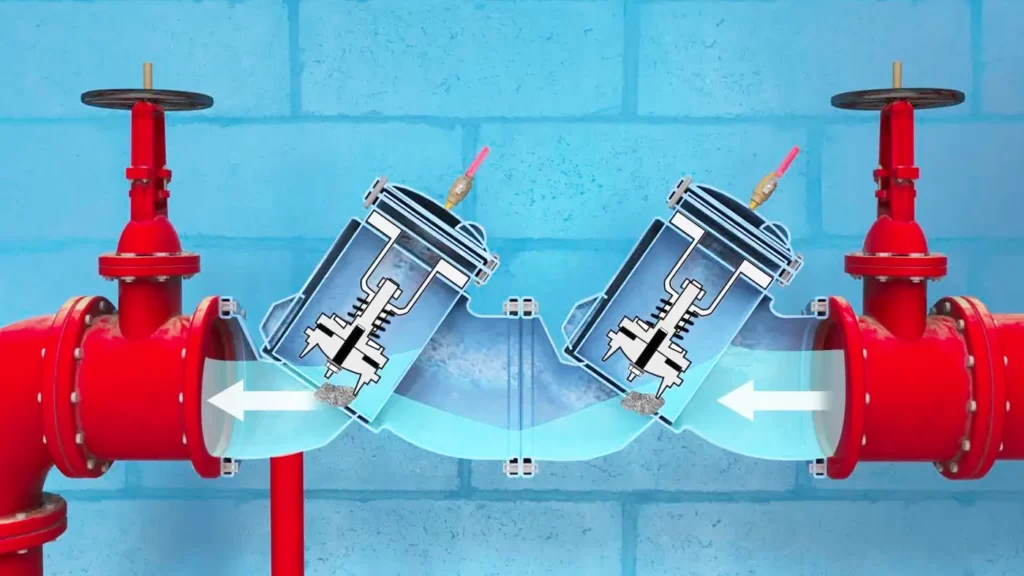

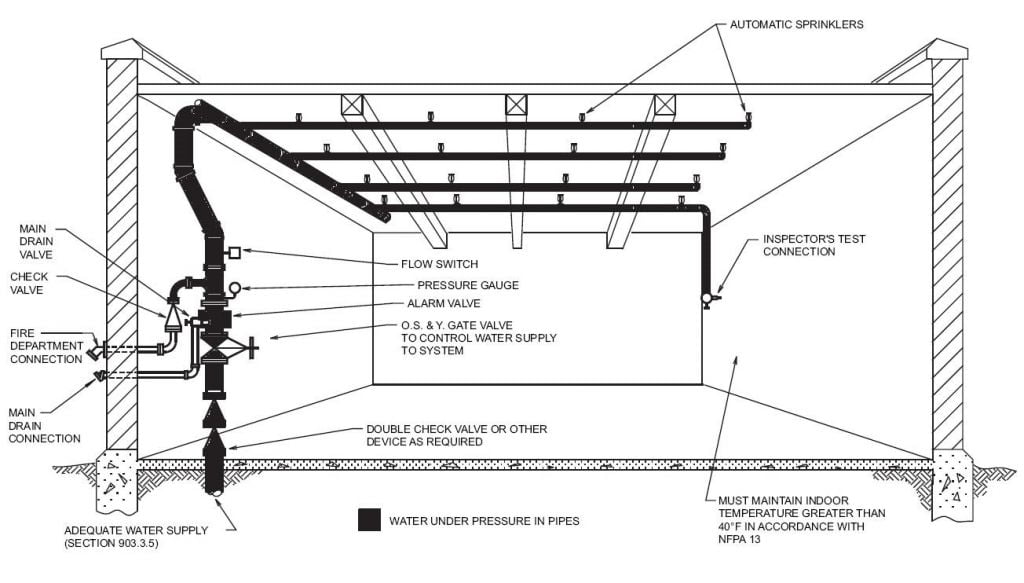

NFPA 13, Standard for the Installation of Sprinkler Systems is based on the general principle that sprinklers must be installed throughout a premises. This contributes to the standard’s purpose of providing a reasonable degree of protection for both life and property. However, there are certain concealed spaces and special situations, such as elevator hoistways and machine rooms where sprinkler protection can be omitted. The need for sprinklers is addressed for three different locations; at the bottom of the pit, at the top of the hoistway, and in the elevator machine room, machinery space, or control room.

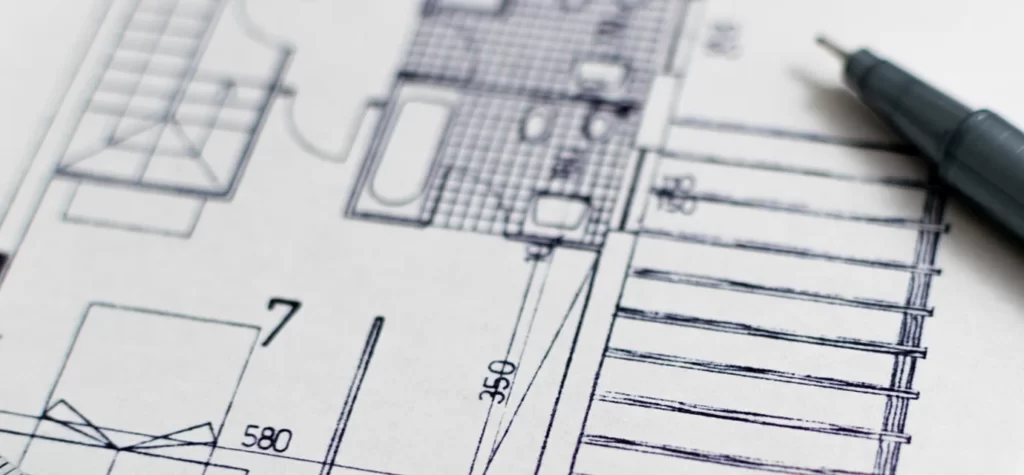

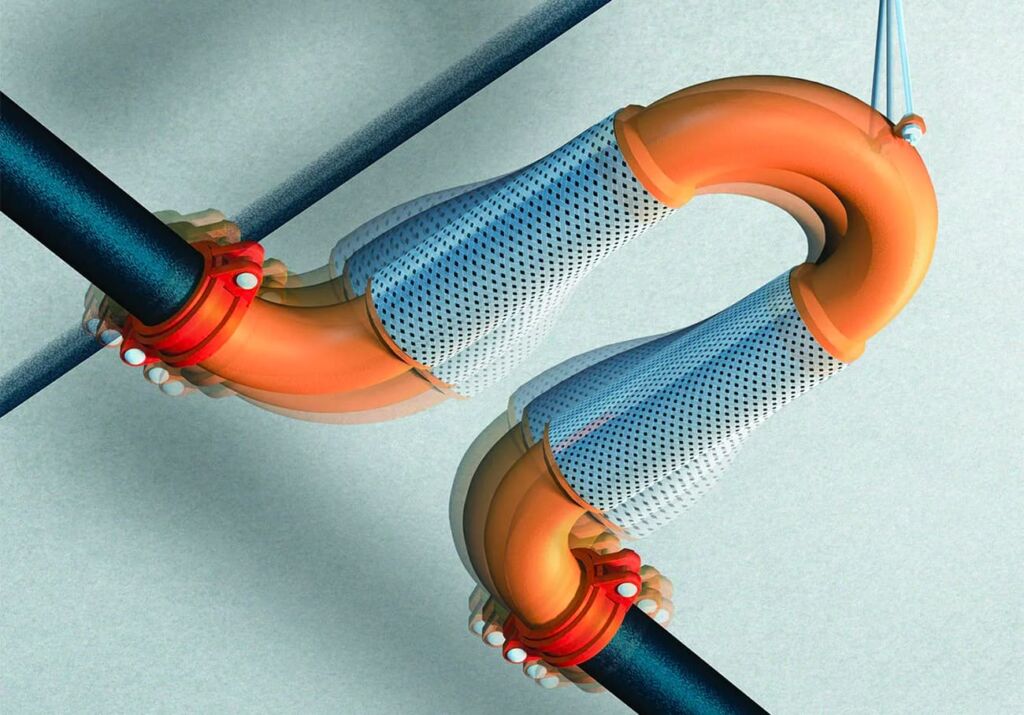

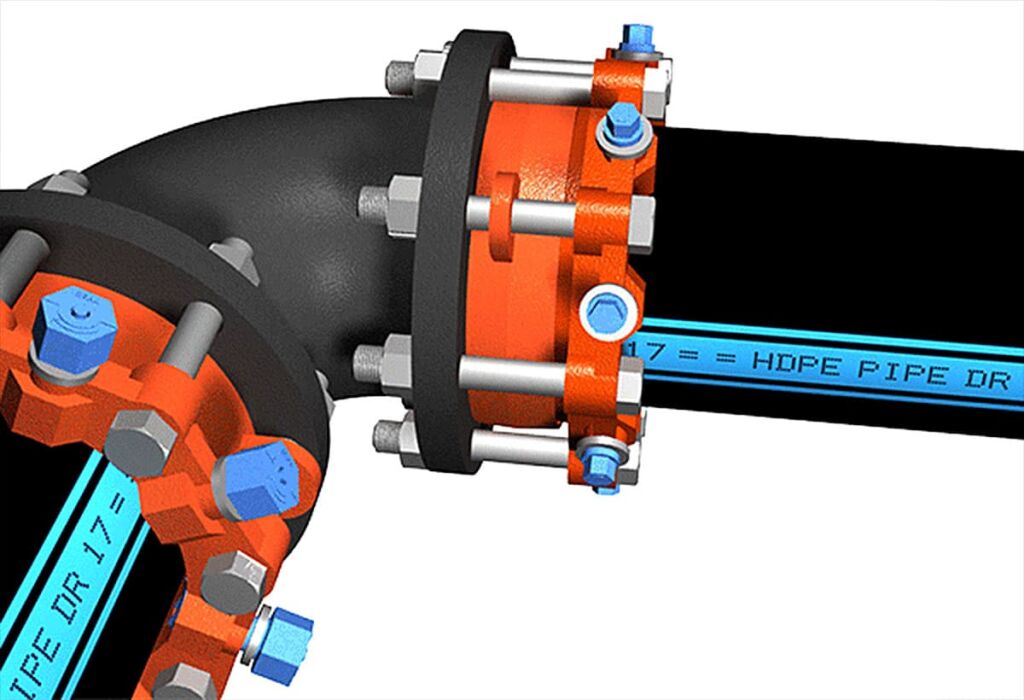

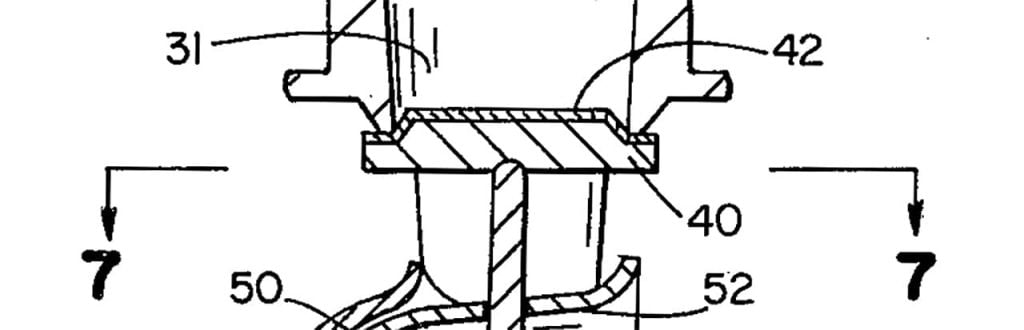

The images below demonstrate hydraulic elevators and traction elevators and show the different locations where the need for sprinklers must be evaluated. Note that sprinklers are shown in the pit and machine room of the hydraulic elevators as those are always required but the top of the hoistway for hydraulic elevators and the pit, top of hoistway, and machine room for traction elevators can also require sprinklers.

Elevator Pit

Sidewall spray sprinklers are required to be installed at the bottom of each elevator hoistway at a maximum of 2 ft (600 mm) above the floor of the pit. The exemption to this is for hoistways that are enclosed, noncombustible, and do not contain combustible hydraulic fluid. This means that the majority of hydraulic type elevators will require this and traction type elevators need it only where the construction of the shaft is of combustible or limited-combustible material.

Top of Shaft

Sprinklers are permitted to be omitted from the top of the shaft where the hoistway is noncombustible or limited-combustible and the car enclosure materials meet the requirements of ASME A17.1, Safety Code for Elevators and Escalators. Any hoistway not meeting those requirements must have an upright, pendent, or sidewall spray sprinkler installed at the top.

Additionally, where elevators utilize combustible suspension means such as noncircular elastomeric-coated or polyurethane-coated steel belts, sprinklers must be provided unless the suspension means provide not less than an FT-1 rating when tested to a vertical burn test of UL 2556 and specific criteria are met.

Elevator Machine Room, Machinery Space, Control room, Control space

The machine rooms for hydraulic type elevators are required to be provided with sprinkler protection. For traction type elevators there are a number of provisions that can all be met in order to omit sprinklers from these spaces. These include the installation being in accordance with NFPA 101®, Life Safety Code® or the applicable building code as well as the space being dedicated to elevator equipment only, protection by smoke detectors or other automatic fire detection, separation from the rest of the building by construction with fire ratings specified by the applicable building code, and no materials unrelated to elevator equipment being stored in the space.

Other Consideration

While the provisions highlighted here from NFPA 13 are relatively straightforward there is added complexity of elevator codes as well as local amendments in many jurisdictions. ASME A17.1 does not permit water discharge in elevator shafts until electrical power to the elevator cab has been shut down. This situation necessitates some special arrangement, such as a shunt trip or a preaction system, to make sure that water does not flow in the elevator shaft until power shutdown has occurred.

Some jurisdictions will have special provisions that modify power shut down provision or they will not permit sprinklers at all out of concerns for first responders utilizing the elevator during a fire. It is also important to note that the discussion above is for buildings that require sprinkler protection per NFPA 13. If the building code does not require sprinkler protection based on occupancy, constructions type, size, or height then the elevator is also not required to be protected.

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

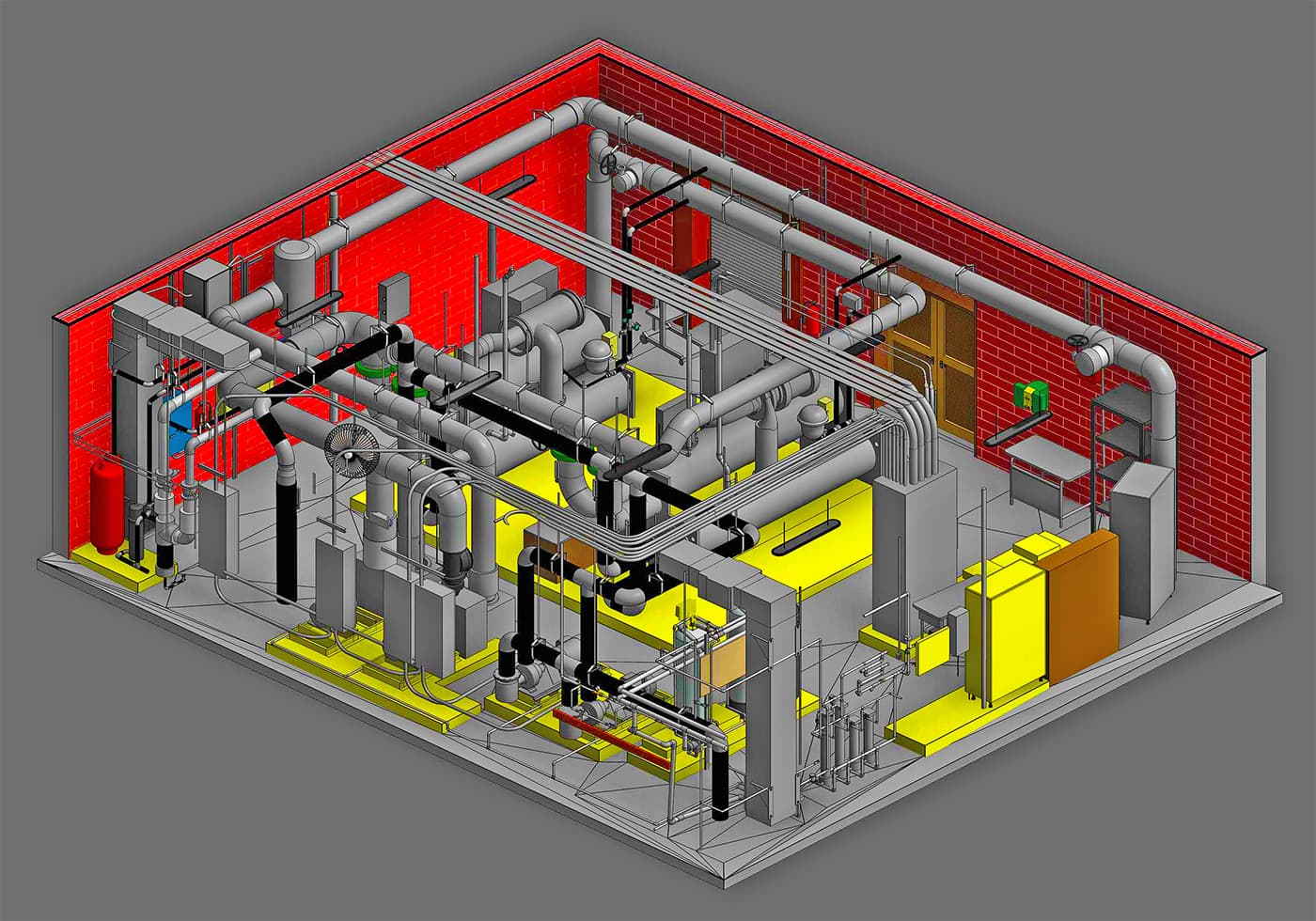

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.