Precision Fire Protection News

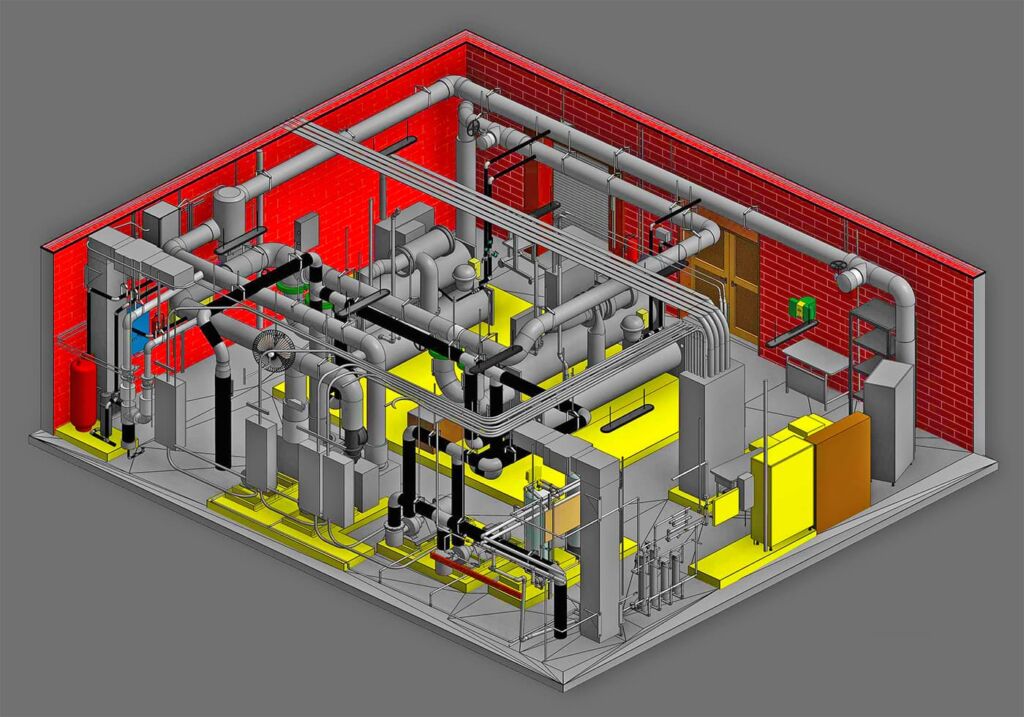

Water Mist Fire Suppression Systems

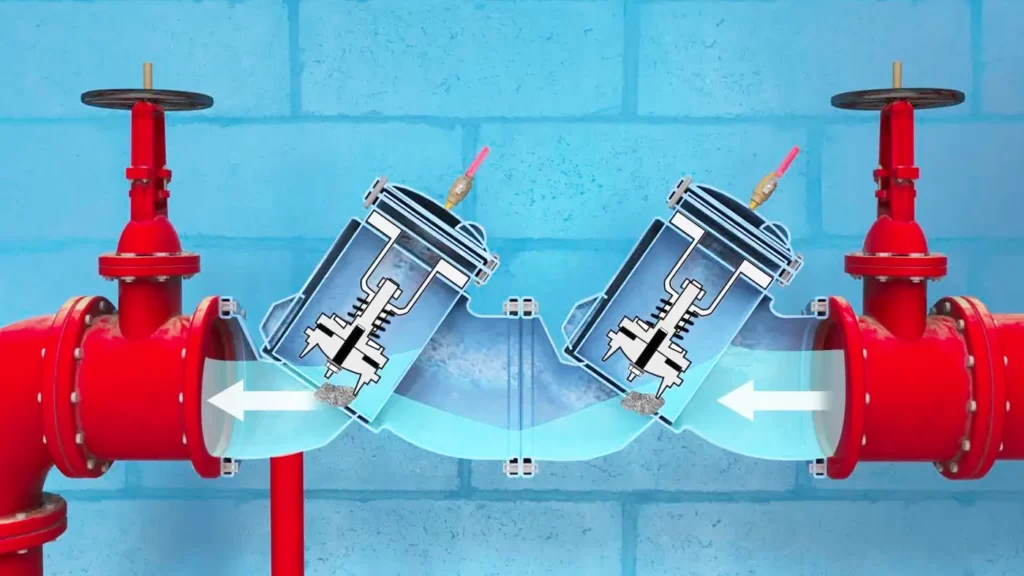

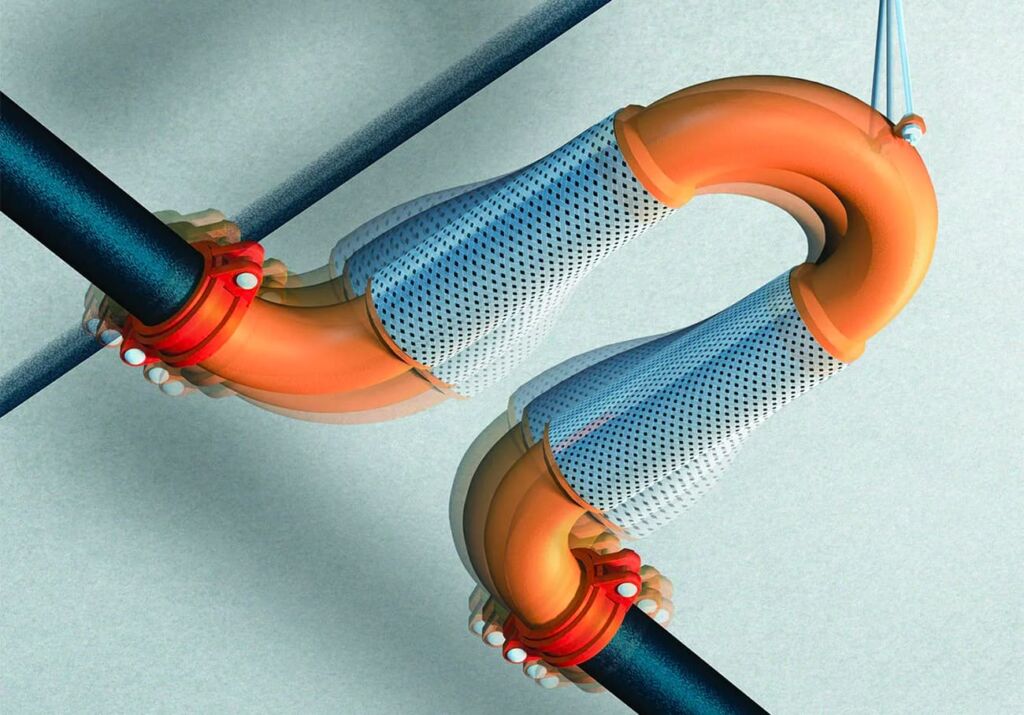

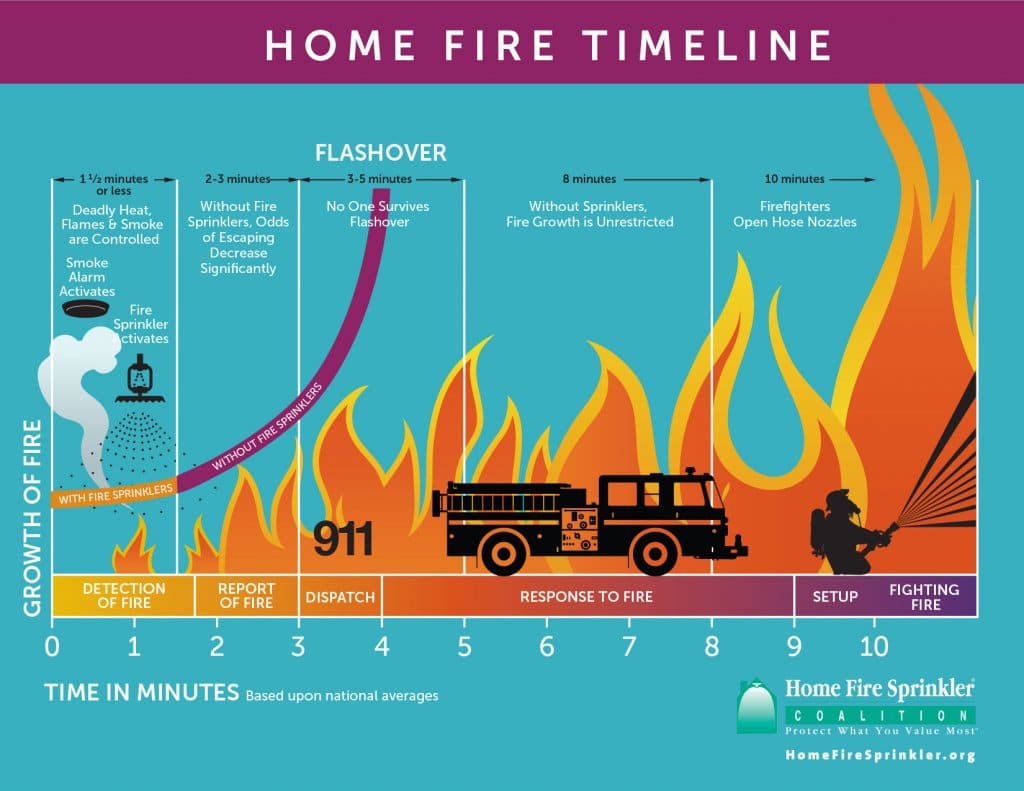

Water mist systems are fire suppression systems that use very small water droplets to extinguish or control fires. These droplets are effective at controlling fires while using less water and having smaller piping than a standard sprinkler system due to the increased cooling effects, oxygen displacement and pre-wetting that the droplet size and distribution provide. Some additional benefits of water mist fire protection systems include reduced water damage and low environmental impact, while one of the trade offs include higher system pressure. This blog will review some of the basics about these systems to help add these systems as an option in your fire protection design portfolio.

The droplet size for water mist systems can vary between 1000 microns and 10 microns. This small droplet size decreases the required application rate, enhances evaporation, and helps reduce oxygen levels to extinguish visible and hidden fires.

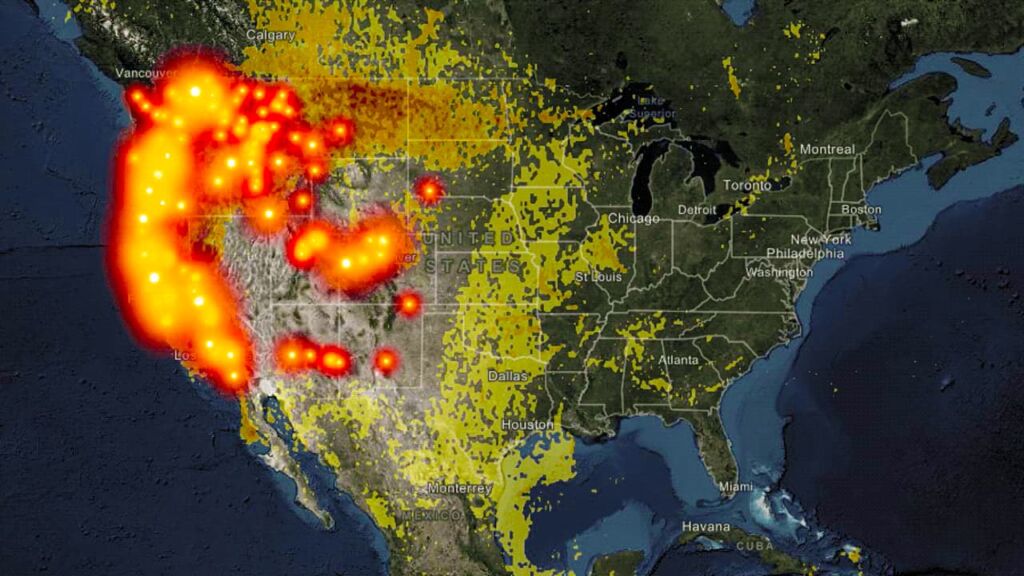

Water mist systems have been used for specific applications (such as maritime) for a long time but starting in the mid-1990’s advancement in the use of water mist systems was propelled by the phasing out of halon and their use as a fire safety system for spaces where the amount of water that can be stored or discharged is limited. In addition, there is a long list of applications in which water mist systems have been listed for use including the following:

- Machinery spaces

- Combustion turbines

- Industrial oil cookers

- Computer room raised floors

- Data processing equipment rooms

- Chemical fume hoods

- Continuous wood board presses

- Shipboard passenger cabins and corridors

- Shipboard accommodation and public space areas

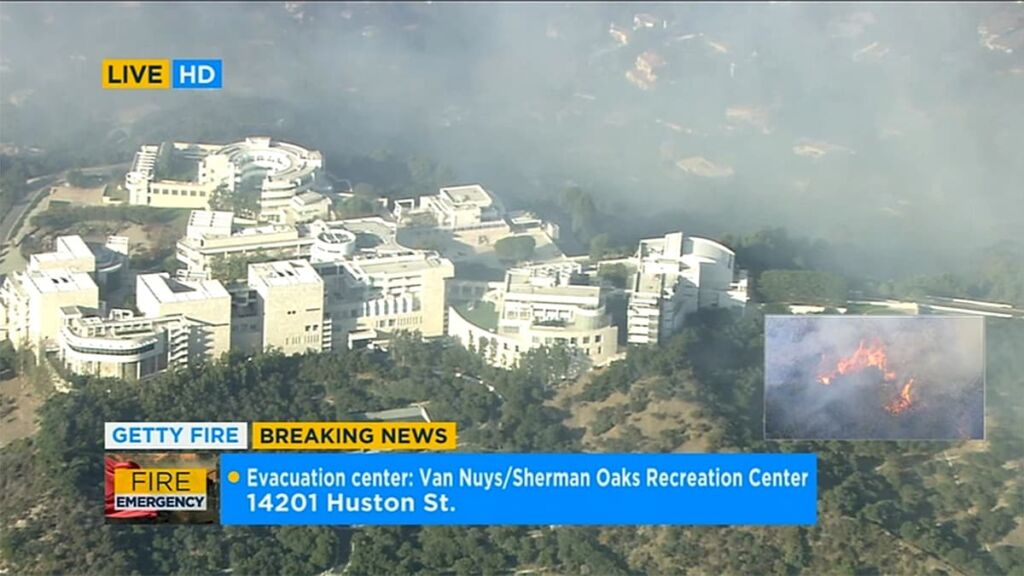

- Road tunnels

- Cable conduit tunnels

Application

There are a few different ways to apply water mist fire protection systems in your building or facility. These types of system configurations will look similar to clean agent system applications because the two systems share several commonalities in how they protect against fires.

Local Application – This configuration is used to protect a specific hazard or object. An example may be the protection of a piece of equipment in a large compartment. The system would be designed to discharge water mist directly onto the object.

Total Compartment Application – This type of system provides protection to all fire hazards and all areas in a compartment. The open nozzles are positioned in a grid so that water mist discharges approximately uniformly throughout the entire volume.

Zoned Application – This type of system is configured to discharge mist from portions of a larger system as required to control fire in a specific part of a compartment. It would be installed in circumstances where the water demand for a total compartment system (i.e., a deluge system), would be beyond the capability of the water supply. Zoning the water mist piping network, however, requires the installation of a detection system that can accurately find the location of a fire.

Occupancy Protection Systems – A water mist system utilizing automatic water mist nozzles installed throughout a building or a portion of a building and intended to control, suppress, or extinguish a fire.

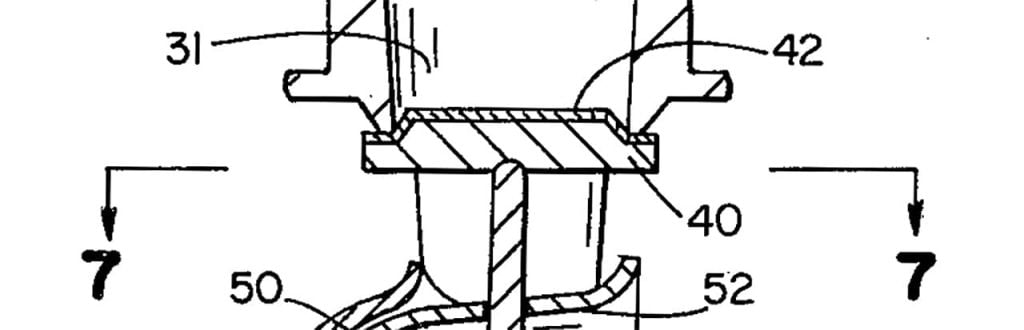

Nozzle types

There are several different types of nozzles that can be found in a water mist fire protection system.

Automatic – Nozzles that operate independently of other nozzles by means of a detection/activation device built into the nozzle. This activation device is typically a heat responsive element or actuator.

Nonautomatic – Nozzles that do not have individual actuators or heat-responsive elements. These types of nozzles are used in deluge systems where the nozzles are always open.

Multifunctional – Nozzles capable of operation using both automatic and nonautomatic means. The actuation of a multifunctional water mist nozzle can be by a built-in detection and activation device and/or by an independent means of activation.

Electronically-operated automatic – Nozzles that are normally closed and operated by electrical energy that is initiated and supplied by fire detection and control equipment.

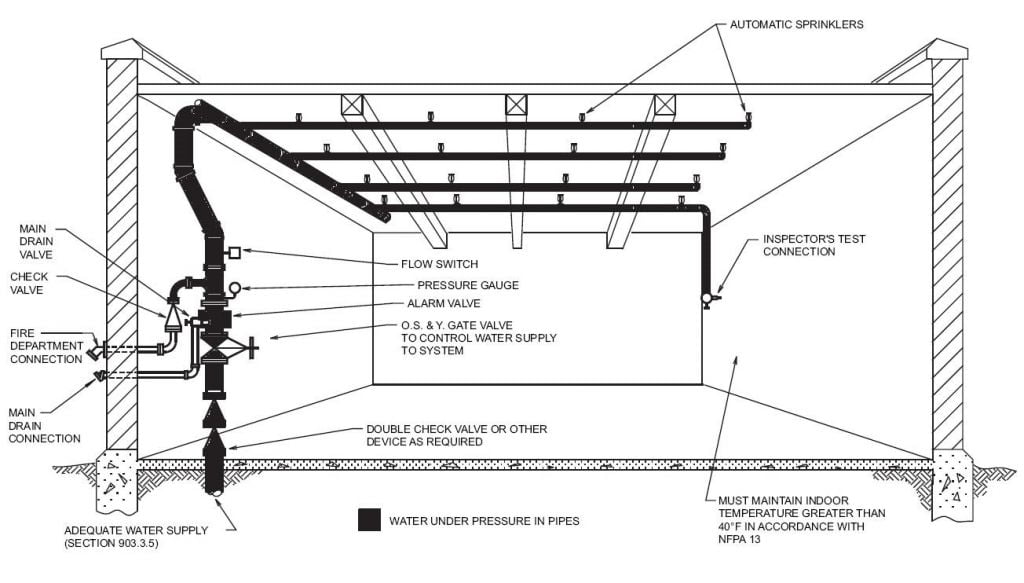

System types

There are various types of water mist systems which are the same categories as the different types of sprinkler systems. Since we recently posted a blog covering the types of sprinkler systems that goes into the details about each type, I’m going to keep this section brief and just give a quick overview.

Deluge System – A water mist system utilizing nonautomatic mist nozzles (open) attached to a piping network connected to the fluid supply(ies) directly or through a valve controlled by an independent detection system installed in the same area as the mist nozzles.

Wet Pipe System – A water mist system using automatic nozzles attached to a piping system containing water and connected to a water supply so that water discharges immediately from nozzles operated by the heat from a fire.

Pre-action Systems – A water mist system using automatic nozzles attached to a piping system that contains air that might or might not be under pressure, with a supplemental detection system installed in the same areas as the mist nozzles. The actuation of the detection system opens a valve that allows water to flow into the piping system and discharges through all opened nozzles in the system.

Dry Pipe Systems – A water mist system using automatic nozzles attached to a piping system containing air, nitrogen, or inert gas under pressure, the release of which (as from an opening of an automatic nozzle) allows the water pressure to open a dry pipe valve. The water then flows into the piping system and out through any open nozzles.

Droplet production methods

Water mist fire protection systems have the option of being either a single fluid (water) or twin fluid (water & atomizing media) system.

Single-Fluid – A single-fluid media system requires one set of distribution piping to transport the fluid to each nozzle. The droplets are then formed in one of the following ways:

- Liquid should be discharged at a high velocity with respect to the surrounding air. The difference in velocities between the liquid and surrounding air should shear the liquid into small droplets.

- A liquid stream is impinged upon a fixed surface. The impact of the liquid on the surface breaks the liquid stream into small droplets.

- Two liquid streams of similar composition collide with one another. The collision of the two streams breaks the individual streams into small droplets.

- Liquid is either vibrated or electrically broken into small droplets (ultrasonic and electrostatic atomizers).

- Liquid is heated above its boiling point in a pressure vessel and released suddenly to atmospheric pressure (flashing liquid sprays).

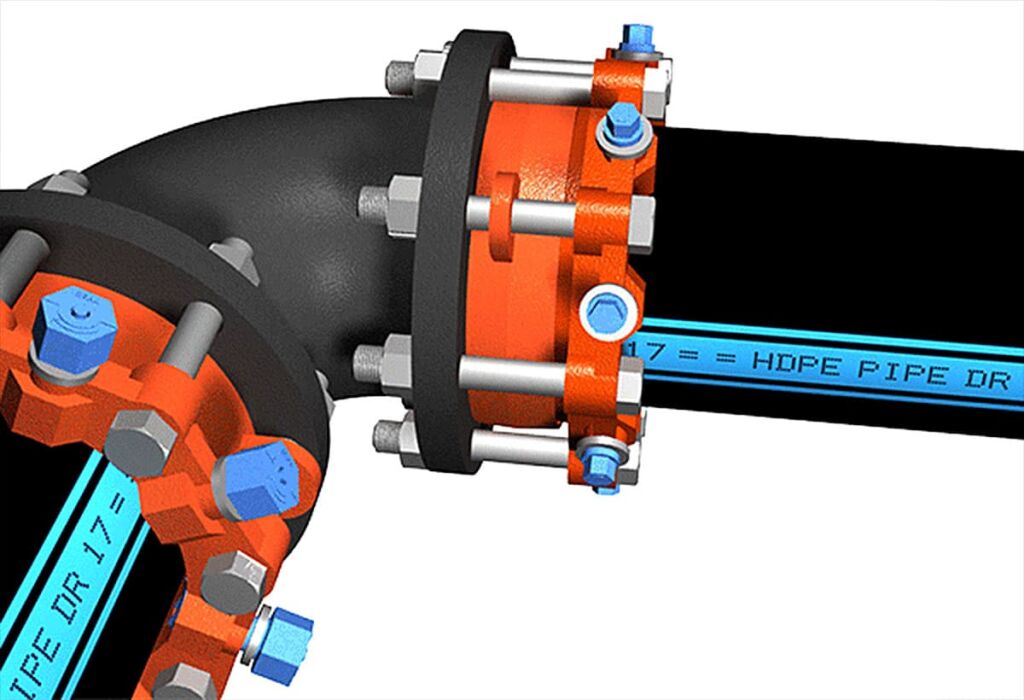

Twin Fluid – Twin-fluid media systems produce water mist (droplet production) by impingement of two fluids delivered from separate piping systems. One set of piping provides a liquid (water) to the nozzle, and the second piping network provides an atomizing fluid/media.

Both single-fluid and twin-fluid systems can be operated in the low, intermediate, or high pressure range, which is based on the greatest pressure that the distribution piping is exposed to, as shown in the table below.

| Low Pressure System | Intermediate Pressure System | High Pressure System | |

| Imperial Units | Under 175 psi | 175 – 500 psi | Over 500 psi |

| Metric Units | Under 12.1 bar | 12.1 – 34.5 bar | Over 34.5 bar |

Conclusion

Ultimately, while water mist fire protection systems have not yet outpaced the prevalence of traditional sprinkler systems there are numerous benefits associated with them to justify their use in many applications.

(SOURCE: NFPA)

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.