Precision Fire Protection News

Hand Sanitizer Storage Hazards

Hand Sanitizer Storage Hazards

Alcohol-based hand sanitizer, part I: life safety considerations

BY KRISTIN BIGDA

These days, it’s hard to walk through just about any type of building—hospitals, schools, dentists’ offices, shopping malls, airport terminals—without encountering hand sanitizing stations. Since the onset of the COVID-19 pandemic, public safety measures have introduced a plethora of requirements, including providing hand sanitizer to occupants where hand washing may not be available or as an extra safety measure, in order to protect communities from the spread of the virus. To meet health and safety requirements, facilities are stocking up on hand sanitizer products, and in many cases are using and storing more than they ever have before.

Many safety professionals may not realize it, but NFPA 101®, Life Safety Code®, as well as NFPA 1, Fire Code, regulate the use of alcohol-based hand rub (ABHR) in most occupancies. When the subject entered the 2006 edition of the Life Safety Code, provisions for this equipment were only found in the chapters for health care and ambulatory health care occupancies. One edition later, in 2009, the requirements were expanded and added to the chapters for educational as well as daycare occupancies. For the 2018 edition, a set of provisions outlining the protection criteria for the use of alcohol-based hand sanitizers was added to Chapter 8, mandating compliance with it for any occupancy chapter that chose to reference it to safely permit the use of ABHR dispensers.

The requirements currently address alcohol-based hand rub sanitizing liquids and aerosols. Expansion of this provision to all occupancies, if permitted by reference, recognized the need for a set of safe regulations for use in any building as the prevalence of the ABHR dispensers had grown substantially and the need for these safety criteria might be more necessary today than ever before.

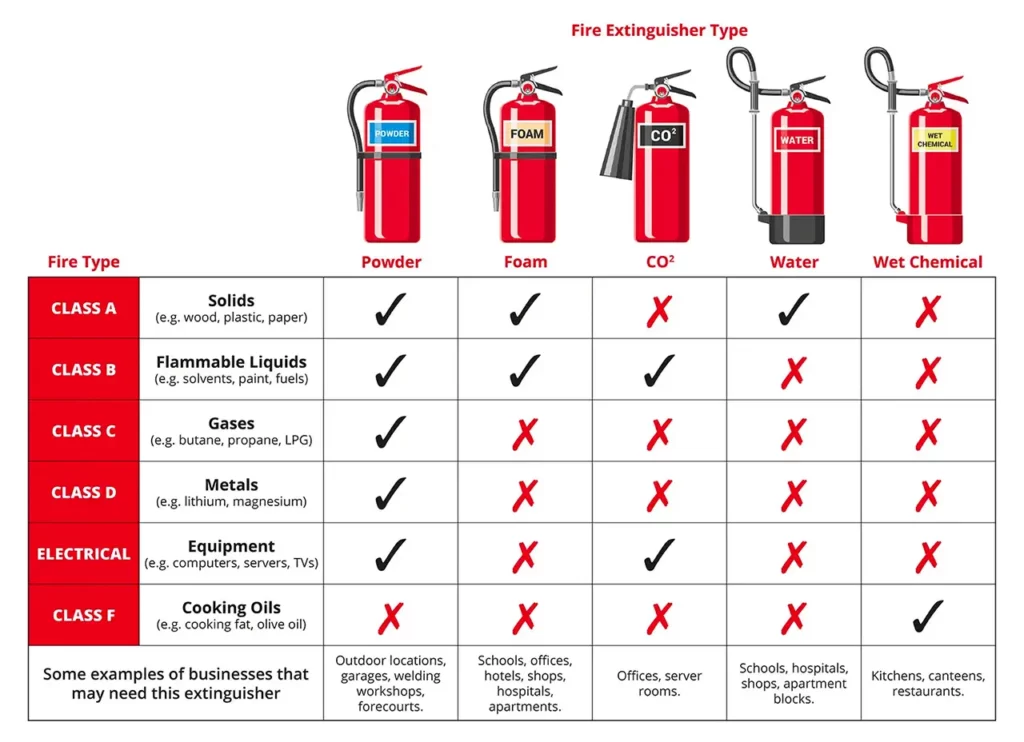

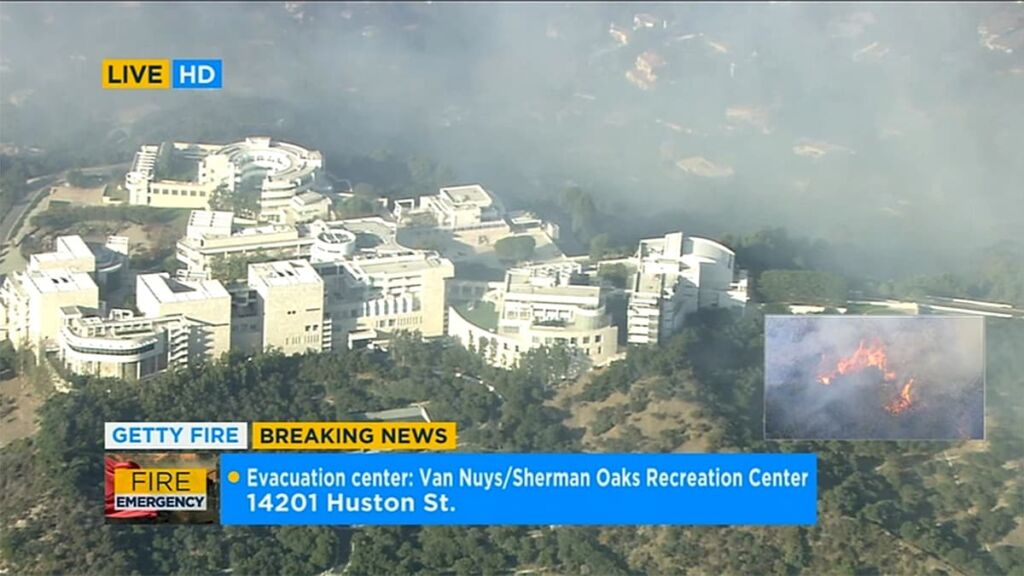

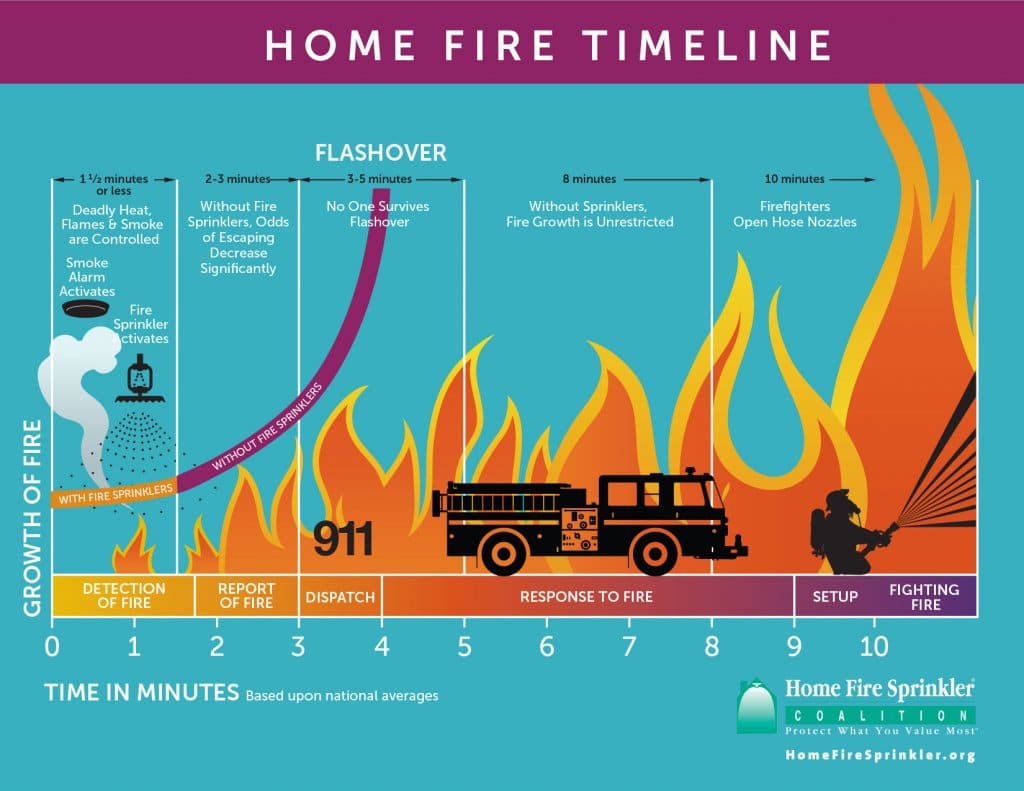

But why, among other fundamental fire and life safety issues, do the codes go into the details of regulating a component as small as an ABHR dispenser? Many commonly found ABHR solutions are classified as flammable liquids and can release ignitable vapors at room temperature and above. When exposed to an ignition source, they can ignite and cause a fire. Improper storage of flammable liquids is also a concern. Facilities today may be stockpiling ABHR solutions and storing them in locations not protected or designed to accommodate hazardous materials in such quantities. Like other hazardous materials, the codes limit the quantities of these materials both in use and in storage and include restrictions on the locations of dispensers containing the liquid. The total quantities of flammable liquids in any area should comply with the provisions of other recognized codes, including NFPA 1 and NFPA 30, Flammable and Combustible Liquids Code.

In addition to limitations on the volume of ABHR in storage, as well as limitations for quantities in use per smoke or fire compartment, NFPA 101 also includes criteria specific to protecting occupants from fire. The capacity of each dispenser, for example, is restricted in order to limit the amount of product in use. Most individual dispensers cannot exceed .53 gallons (2.0 L), less if the dispenser is located in a corridor or space open to a corridor. That means a gallon container of ABHR with a pump to dispense the liquid, a common hand-sanitizer setup the moment, exceeds the maximum capacity. It should also be noted that educational occupancies do not permit ABHR dispensers in corridors or spaces open to corridors. While most occupancies provide a simple reference to the core set of provisions in the code, educational occupancies retain their own list, which differs by this one criteria that limits the location of ABHR dispensers in corridors. This is also likely a very common violation during this time as schools are being asked to provide hand sanitizer is so many locations throughout the building.

Dispensers are required to be separated from each other by at least 4 feet of horizontal spacing. This limits the probability that a fire could spread from dispenser to dispenser. Dispensers also cannot be installed within specific distances above, to the side of, or below an ignition source. Dispensers can be installed above carpeted floors only where the area of the building is sprinklered. This limits the potential for combustible floor covering to contribute to the fuel load and fire growth should ABHR that may have leaked or pooled on the floor ignite. Finally, the code provides a detailed requirement mandating the specific operation of the dispensers. Ensuring proper operation, whether manual or automatic activation, reduces the likelihood that extra solution will leak and form a pool of flammable liquid on the floor below.

As these points demonstrate, the issues related to ABHR extend well beyond the storage and protection of large amounts of the liquid. Safety professionals also need to understand the life-safety requirements related to hand sanitizer and dispensers, especially considering the potentially long-term nature of the current pandemic.

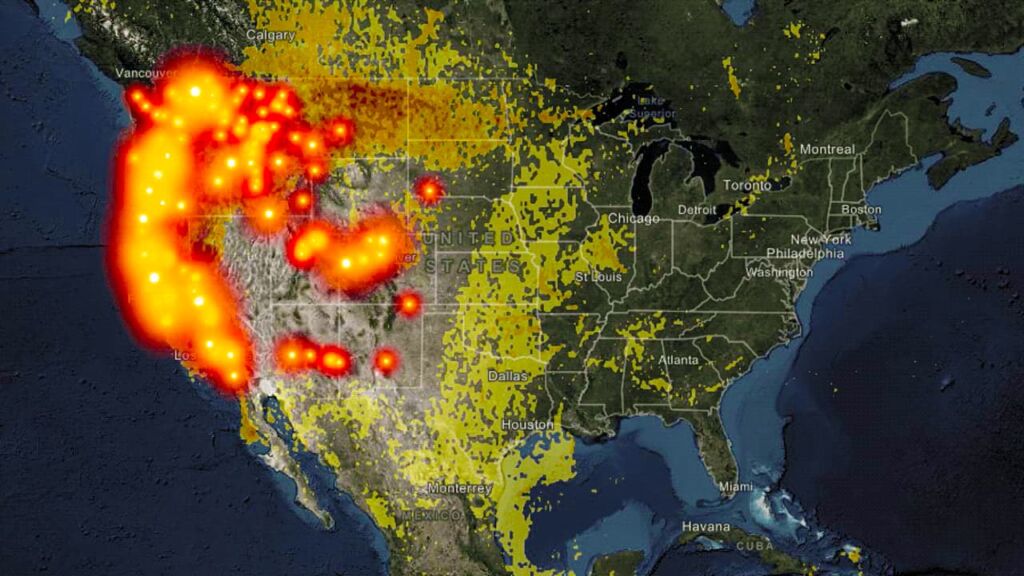

Alcohol-based hand sanitizer has been an important tool in preventing the spread of COVID-19, but this flammable liquid can be hazardous when stored in large quantities. The Centers for Disease Control and Prevention recommends consumers use an alcohol-based hand sanitizer that contains at least 60 percent alcohol. With flashpoints typically around 63°F, NFPA 30, Flammable and Combustible Liquids Code, classifies these liquids as Class IB flammable liquids.

Because of the increased demand, many types of occupancies may find themselves in need of a larger-than-usual storage of hand sanitizer. It is important to understand the protection criteria required for varying quantities and methods of sanitizer storage.

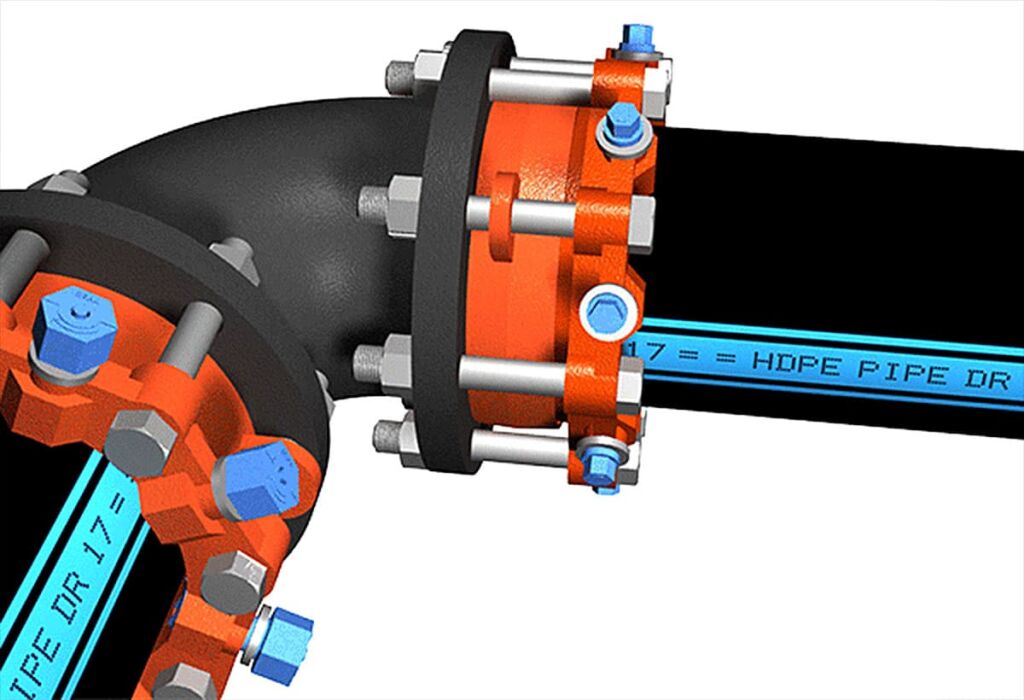

When determining when and how to protect the storage of hand sanitizer, it is important to gather information to allow you to make the correct design decisions. First, it is important to know which standards to follow. If you are dealing with a mixture that is less than 20 percent alcohol, NFPA 13, Standard for the Installation of Sprinkler Systems, contains all the requirements you need to follow. If it is above 20 percent alcohol, then you will need to consult NFPA 30.

To determine design criteria, you will first need to know how much hand sanitizer is being stored. It is important to note that the quantity of sanitizer stored does not include sanitizer that is in use, such as the liquid contained in wall-mounted dispensers. Requirements for the use and storage of small quantities of sanitizer can be found in NFPA 101®, Life Safety Code®. If the quantity is more than 5 gallons, it needs to be protected in accordance with NFPA 30.

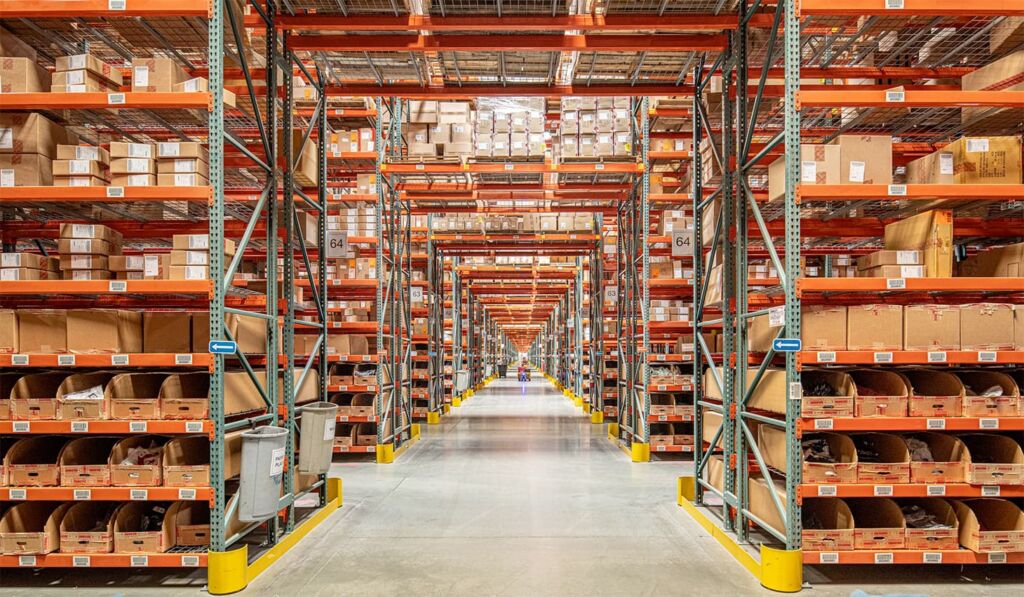

You also need to know how the sanitizer is being stored: in racks, palletized on shelves, or stacked. You also need to be aware of what containers the sanitizer is stored in, since they can vary greatly; examples of acceptable container material include metal, plastic, and glass. The material the container is made of will also dictate the volumetric size of the container that the hand sanitizer can be stored in. A complete list of acceptable containers is located in section 9.4.1 in NFPA 30.

Once you know the storage details, you can use the concept of maximum allowable quantities (MAQ) to determine how to protect it properly. MAQ is the amount of hazardous materials that may be stored, used, or dispensed within a single control area. If you use a flammable liquids storage cabinet, then the MAQ increases 100 percent. The MAQ increases another 100 percent if the storage is in an area where sprinklers are installed. These increases are cumulative with each other as well, which means if you have a starting MAQ of 120 gallons of a Class IB liquid in a storage cabinet that is sprinkler protected, the MAQ increases to 480 gallons. It is also important to note that Class 1 liquids are not allowed to be stored in a basement and that large quantities of flammable liquids will require spill containment. Additionally, certain occupancies, such as business and educational, have special MAQ requirements are much more restrictive in the quantity of liquid allowed.

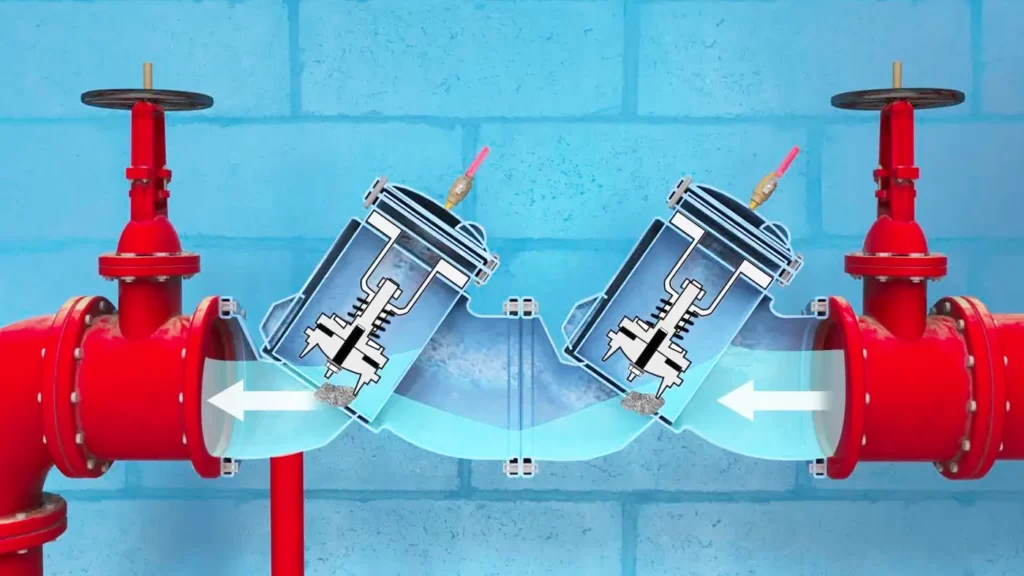

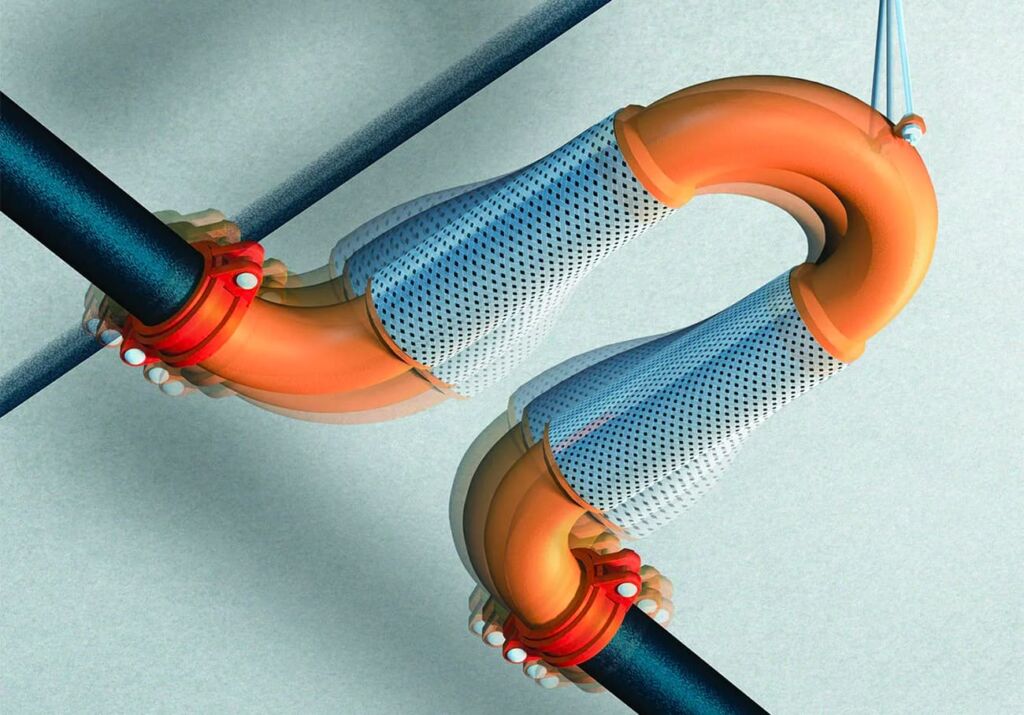

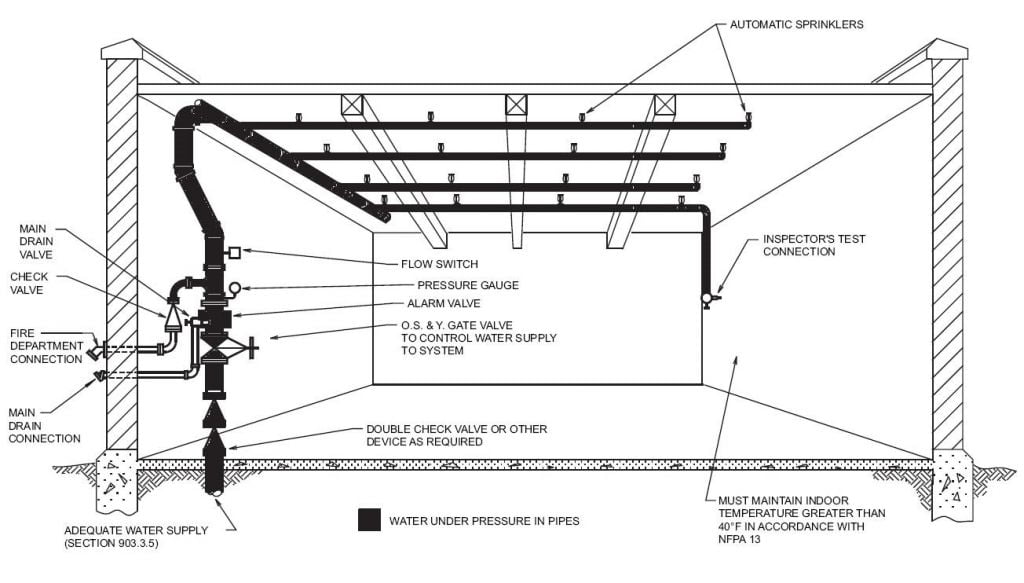

In NFPA 30, Chapter 16 contains several flow charts that will help users determine what fire protection design criteria and schemes are needed. NFPA 30 allows fire protection to be provided by a sprinkler system or a foam-water sprinkler system.

Alcohol is considered a water-miscible liquid since it mixes easily with water. According to the tables in Chapter 16 of NFPA 30, water-miscible liquids in metal containers that are less than 50 percent alcohol can be treated as Class III commodities, and if they are less than 20 percent alcohol they can be treated as Class I. Since hand sanitizer is usually above 60 percent alcohol, these generalizations don’t apply. Instead, NFPA 30 points you to tables within Chapter 16 based on the type of metal container and whether it is being protected with a sprinkler or foam-water sprinkler system. In these tables you will find maximum storage height, maximum ceiling height, required aisle width, and required sprinkler arrangement, as well as whether in-rack sprinklers are required. A similar method can be followed for nonmetallic containers.

It is important to understand that sprinkler systems are designed to protect against certain hazards, and that increasing those hazards can cause your fire protection system to be overwhelmed. This issue can be addressed by developing a change management plan that triggers safety and compliance reviews when certain changes occur.

Although NFPA 13 usually contains all of the requirements for the installation of sprinkler systems for the storage of flammable and combustible liquids, NFPA 13 and NFPA 30 also work in harmony to help ensure sprinkler systems are designed in a way that can help save people and property.

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

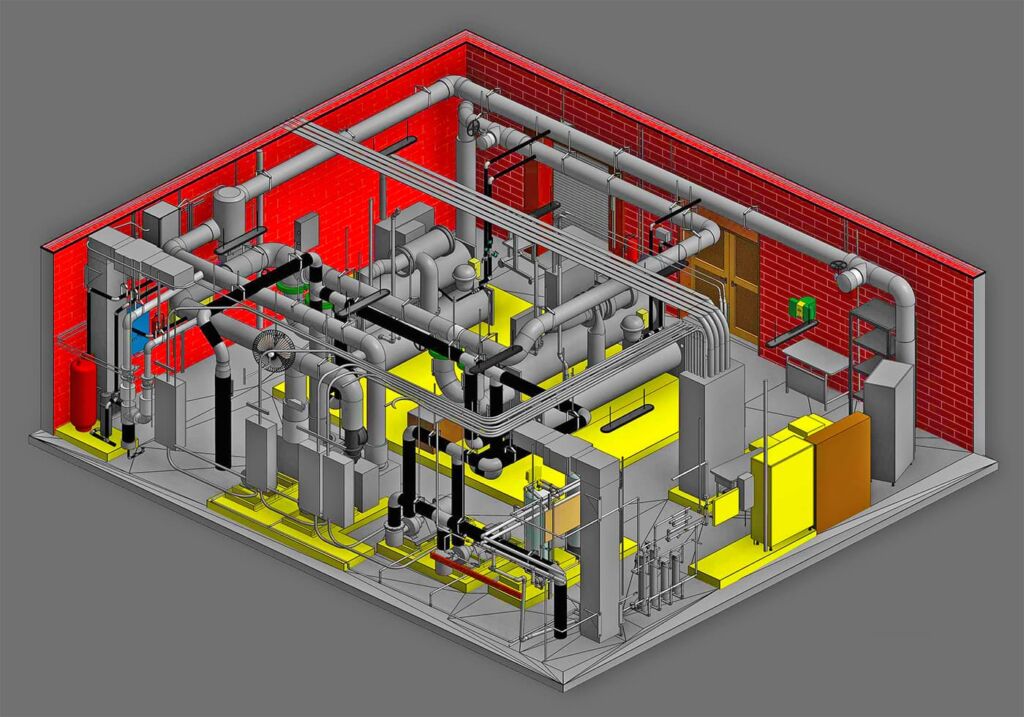

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.