Precision Fire Protection News

Aqueous Film Forming Foam

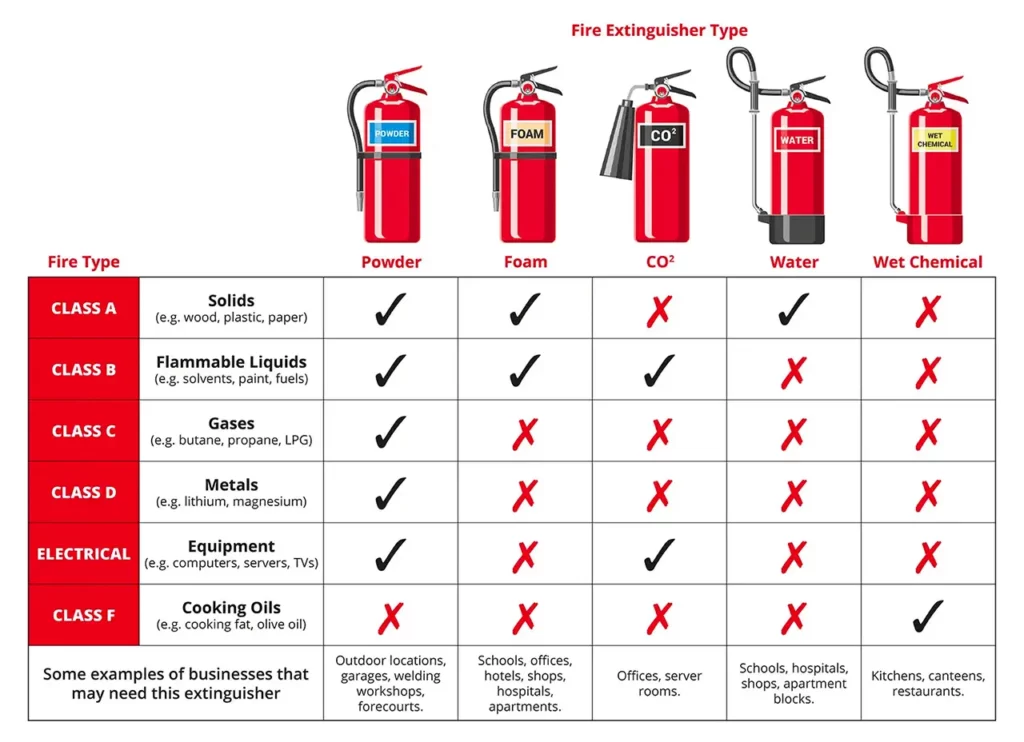

For decades, aqueous film forming foam, or AFFF, has been the gold standard for extinguishing dangerous liquid fuel fires. Now, with AFFF being rapidly phased out and new firefighting foams being developed, the fire protection world braces for what’s next.

BY JESSE ROMAN

ON THE MANTLE IN HIS HOME OFFICE, beside antique fire alarm boxes, model fire trucks, and old fire helmets, Jeremy Souza once kept a collection of slightly stranger mementos: about a dozen jars filled with various amber liquids.

For years, as a firefighter and later deputy fire chief at T.F. Green Airport in Providence, Rhode Island, Souza would lug the jars to trainings for new firefighters. He’d pass the jars around and explain how the liquid inside, a chemical substance called aqueous film forming foam, or AFFF, worked to extinguish liquid fuel fires and even perform other feats of magic around the fire house.

“Back in the day at the airport, we used this stuff for just about everything short of brushing our teeth,” said Souza, who is now an engineer specializing in foam suppression systems at Code Red Consultants, a Massachusetts-based fire safety company. “AFFF is a wonderful degreaser. Take a half gallon of AFFF concentrate, throw it on a garage floor and hose it down, and the stain is gone. I would say that is more of an airport thing—municipal fire departments would never have dealt with quantities of foam like that. But we had loads of it.”

For a certain generation of specialized firefighters tasked with protecting airfields, oil and gas facilities, and military installations, Souza’s experience is probably relatable. For nearly six decades, AFFF has been as indispensable to their jobs as water is for structural firefighters, owing to its unique ability to quickly snuff out even the nastiest liquid fuel fire under a blanket of chemical bubbles. In the dangerous scenarios that can play out when large stores of fuel are threatened by fire, AFFF’s qualities as a fast and reliable suppression agent have literally been a lifesaver.

But that will soon change. As part of the National Defense Authorization Act passed by Congress in late 2019, the US Navy is required to publish a new military specification for a fluorine-free foam by the end of January 2023 and is required to make a full transition to fluorine-free firefighting foams by October 2024. Congress had imposed earlier mandates on the FAA to transition airports to fluorine-free foams by October 2021, but that deadline was missed. The new MIL-SPEC regulations now being written will pave the way for both airports and military bases to make the switch, which by all accounts will be a massive undertaking requiring a significant investment. According to a report to Congress last October, the military still has about 3 million gallons of AFFF concentrate remaining at its facilities, and it is estimated that civilian airports have at least three times that.

Although the military has yet to officially approve a fluorine-free foam for use at its facilities, there are now a few dozen products that have passed performance tests developed by credible testing and approval authorities, such as UL. Of the 70 or so fluorine-free foam products now on the market, about half have credible approvals/listings, according to the Research Foundation’s roadmap report.

The NFPA standards that address foam suppression—including NFPA 11, Standard for Low-, Medium-, and High-Expansion Foam, and NFPA 30, Flammable and Combustible Liquids Code, as well as NFPA’s suite of standards for the protection of airfield and airport facilities—focus mainly on hardware and do not stipulate which type of foam can or should be used. As such, little has changed so far in NFPA 11 regarding the transition to fluorine-free foam, other than adding information about the new foams in the Annex, said Back, who is a member of the technical committee. Since the new foam concentrates are still undergoing testing, there hasn’t yet been a need for significant changes to the design or protection strategies outlined in NFPA 11 for fixed-system foam application.

“The testing data seem to suggest that you’re probably still OK using these new products in legacy systems in many applications, as long as you go through the right process of getting it approved for that application,” Back said. An important caveat to that, however, is that the new foams have not yet been tested by a major real-world event. If a catastrophic incident did reveal flaws in how well the new foams perform within existing system designs, it would likely result in the technical committee revisiting those design parameters, Back said.

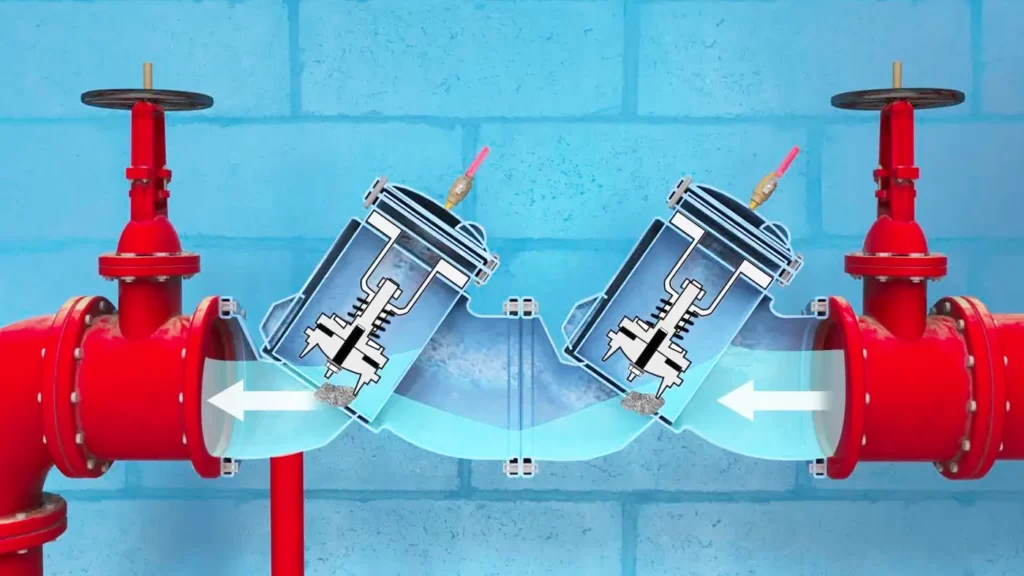

But this does not mean that facilities can simply replace the existing AFFF concentrate in their fixed systems with a fluorine-free foam. In fact, the experience of facilities that have made the switch suggests an array of new challenges and considerations.

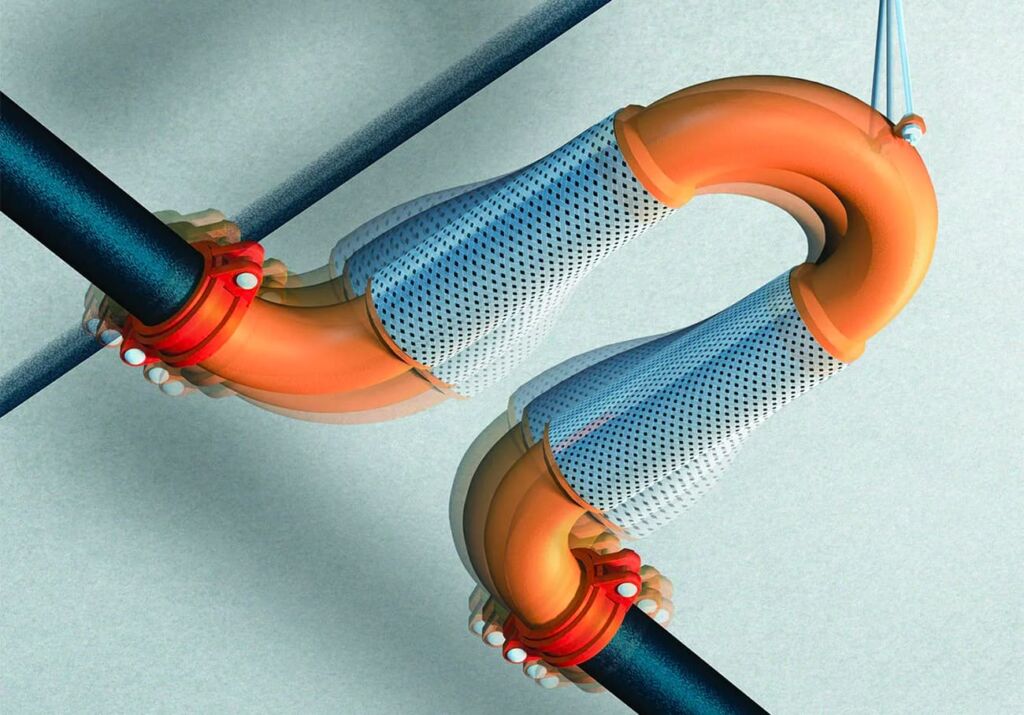

As with fire departments, the first problem facilities face is figuring out which new foams will meet their needs. Whereas AFFF is a one-size-fits-all solution that can put out most fuel fires the same way every time, the effectiveness of a fluorine-free foam depends on myriad factors, including the type of fuel being protected, the depth and temperature of the fuel, and more. Those factors inform which foam concentrate is used, which in turn dictates the necessary equipment and discharge devices, Souza said. “It becomes really specific to the application,” he said. “You can’t do anything until you answer the question of which concentrate you’ll use, and everything else flows from that.”

Once the concentrate is selected, the engineering work is only just beginning. For one thing, the AFFF in the jars on Souza’s mantle have a viscosity similar to water. By comparison, some fluorine-free concentrates are so thick that you could turn a glass of it upside down and none would spill out. Others have a consistency more like ketchup or Jell-O. “The existing equipment is not calibrated correctly to handle that,” Souza said. “I wish we could say to users, ‘here are the new bubbles, put it in your system and it will work.’ But it’s way more complicated than that.”

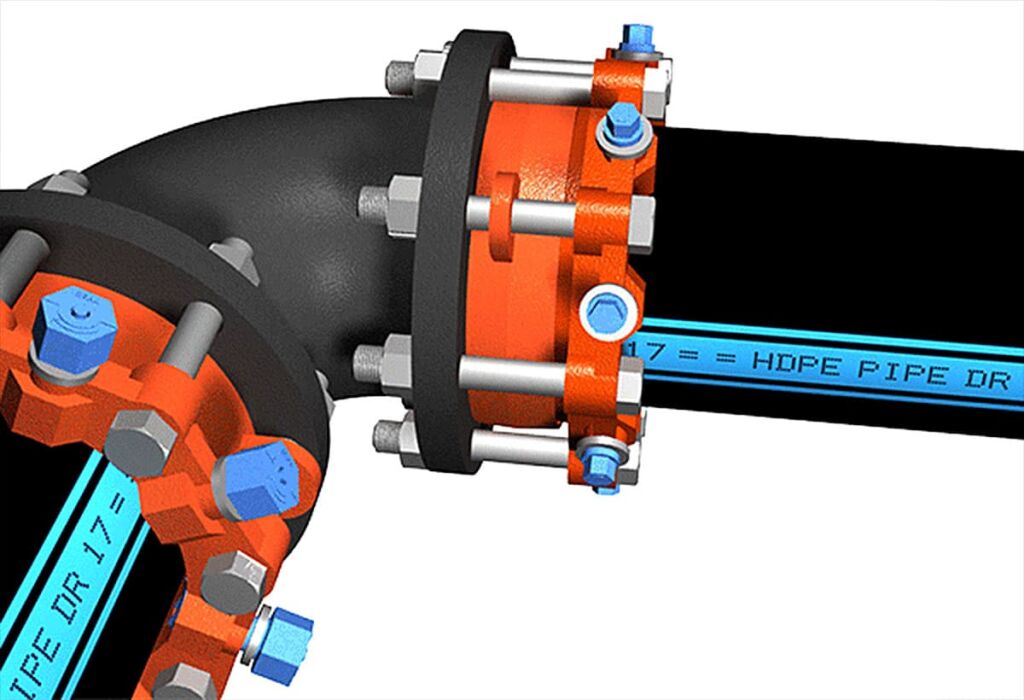

All of those issues were in play on a project Souza led recently to design and install a new fluorine-free fixed foam system at Nantucket Memorial Airport in Massachusetts, one of the first such undertakings at an airport in the US. The viscosity problem, coupled with other factors including the increased densities and application rates required for the new foams to work, were engineering challenges that weren’t cheap to solve. Virtually every part of the foam system that protected the airport’s fuel storage and transfer area had to be replaced, a scenario that’s likely indicative of what most airfield facilities will face.

“As we started digging into what it would require to switch to a fluorine-free system, it just snowballed from the engineering standpoint,” Souza said. “Pretty much every airport is completely freaking out about how they are going to get this foam thing taken care of.”

Oil and gas facilities have faced similar engineering challenges, Hawthorne said. Larger companies such as Shell, Chevron, Exxon, and BP have conducted extensive studies on the performance of fluorine-free foams and are either in the process of converting their AFFF systems or have already done so. “Some of the hardware needs to be recalibrated, some of it needs to be replaced. It’s the same kinds of questions with the storage tanks and fire trucks,” said Hawthorne, noting that municipal fire departments may also need to replace or recalibrate fire pumps on trucks that carry foam. The new hardware and specifications have also meant that the workers who service and maintain the equipment need to be retrained, as do any firefighters that work at the site. That involves rewriting training manuals and reworking operating procedures, Hawthorne added.

There is also the lingering issue of how to inform and educate outside firefighters and contractors about the new foams and systems. Many oil and gas facilities do not employ a full-time fire department onsite and rely instead on local municipal fire departments to assist during an incident.

“I may have a terminal that is going to switch out the foam to fluorine free, but the municipal fire department I’m working with is still using AFFF,” Hawthorne said. “If you just spent a lot of money to replace the AFFF, you don’t want your mutual aid partners to come in and contaminate your facilities if you have a fire, so we have to work with them to figure out how to handle that. The petroleum industry is still grappling with that challenge across the world, from Rotterdam to Singapore to New York.”

THE ROAD AHEAD

Though numerous petroleum facilities and some fire departments have already made moves to replace AFFF, a large percentage remain reluctant to do so. Back estimates that roughly 20 percent of the petroleum industry has made the switch, but little data is publicly available to confirm the actual number. “I think the rest of the industry is still playing a wait-and-see game just to see whether the products get a little bit better,” he said.

One issue consistently raised by experts is what is referred to as “transition regret.” Since the early 2000s, the industry has moved through a number of different AFFF formulations, with each eventually phased out due to health and environmental concerns. Although fluorine-free foams may not contain PFAS, nobody can say yet with certainty that the chemicals they do contain won’t eventually be found to be hazardous in other ways. “Nobody wants to transition to fluorine free and then in three or four years have to transition again,” Hawthorne said. “A large refinery might have 20,000 to 40,000 gallons of foam concentrate, so replacing all of that is no small matter.”

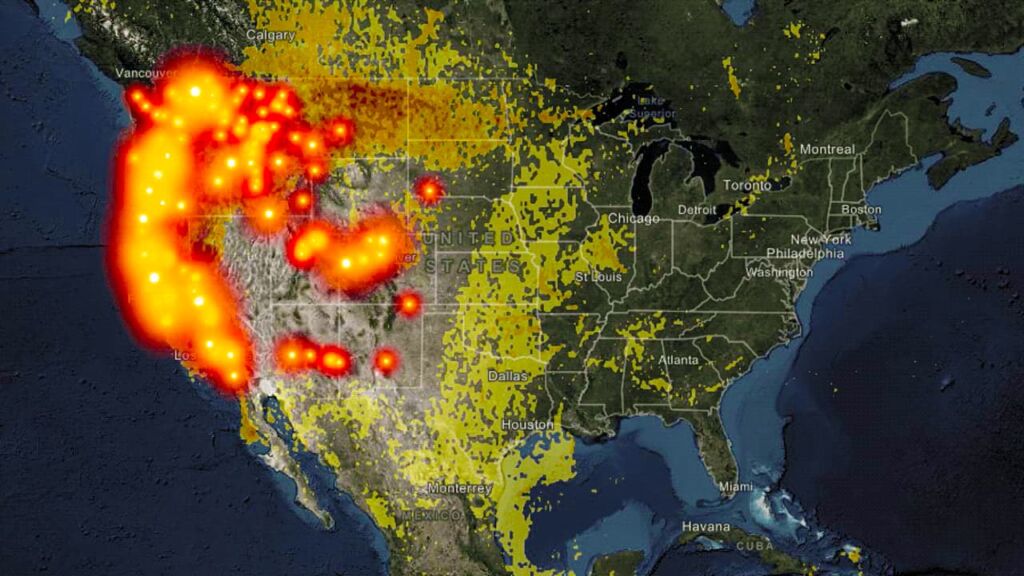

Municipal fire departments must consider numerous factors as they determine when and how they might switch to fluorine-free foam. In states where AFFF has been banned or restricted, the movement has been swifter as the sunset date for AFFF approaches. Resources, department size, and what types of facilities a department protects are all factors that likely contribute to how well-informed individual fire departments are on the foam issue, Hawthorne said.

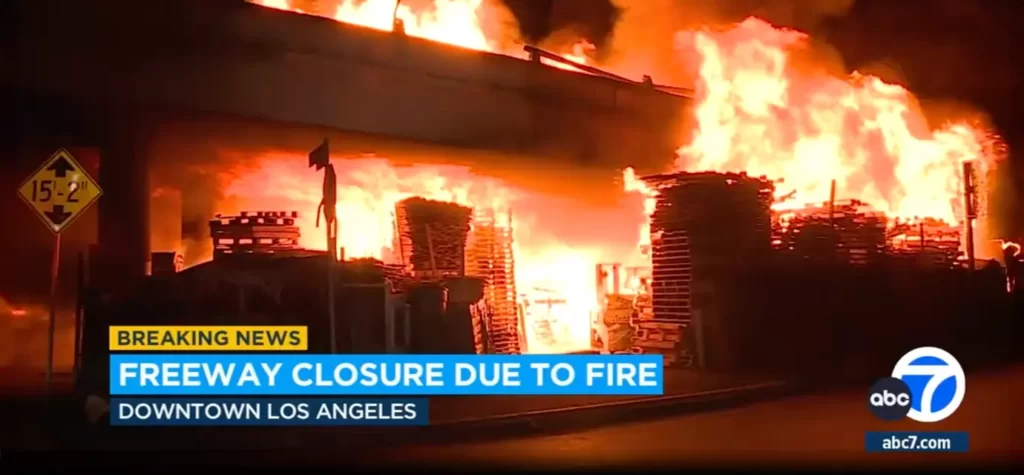

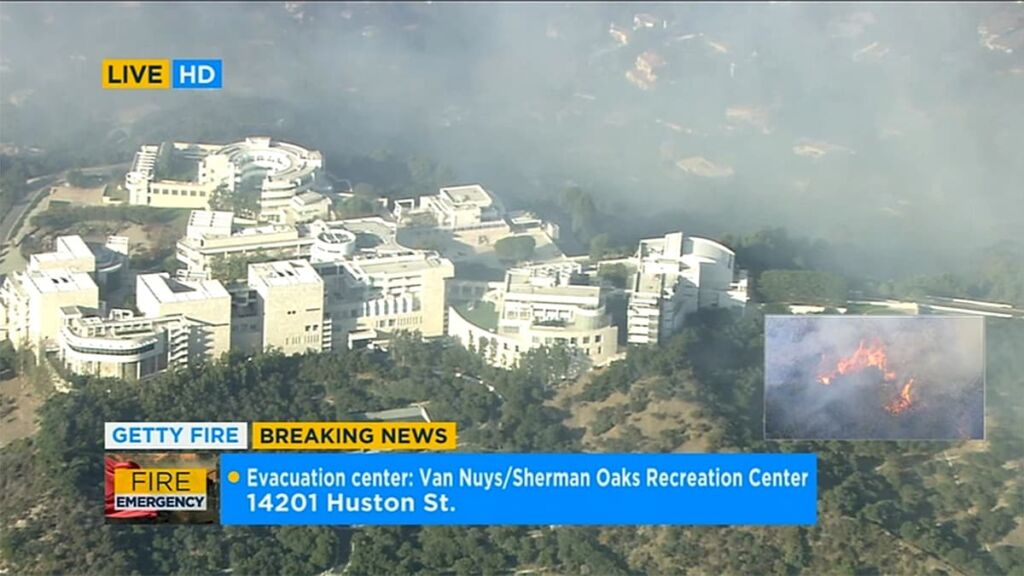

“Big-city departments like Chicago, LA, Atlanta, New York—particularly the more progressive ones that also have airports to protect—are probably actively engaged in this transition,” Hawthorne said. “When you look at smaller departments, which are the vast majority of fire departments in US, I think we would find they are either unaware, or are aware and not sure what to do. That was the whole purpose of the Foundation’s roadmap report—to provide those fire departments with a guide for how to do it.”

There is reason to believe that the Foundation’s guidance document could become very important very soon. Many experts like Hawthorne believe that the effort to replace AFFF is going to shift into high gear as soon as the new fluorine-free military specifications are published early next year. The first fluorine-free foams that the military officially approves will likely trigger large purchases by the US government and high-profile airports, which will signal to hesitant petroleum facilities and fire departments that it is time to move forward. “When that happens, fire departments all over US are going to say ‘we now have foams that we can use,’ and will start to make the jump to fluorine free,” Hawthorne predicts. New firefighter protocols and training, along with updated equipment and other key changes, will need to follow soon after, experts say.

Acknowledging that the journey has only just begun, the Research Foundation has applied for additional funding to continue its efforts to keep stakeholders informed. The proposed new project will aim to generate recommended best practices and tactics guidance for firefighters using the new fluorine-free foams. The results could help inform badly needed new training programs for departments across the world as they make the transition away from AFFF.

Ongoing research will also be vital, Back said, to stay on top of changes as foam technology continues to evolve. “We’ve done hundreds of fire performance tests over the past five years on the various capabilities of these products and there is no question that the manufacturers are tweaking their formulations and making them significantly better as we go,” he said. Some manufacturers even claim to have developed fluorine-free foam concentrates with low enough viscosities to work with minimal changes to existing infrastructure.

Regardless of the final capabilities of new-generation foams, it will matter little if facilities managers don’t spec the right foam or if firefighters aren’t adequately trained to use it. Hawthorne, Back, and others believe that the new foams are good enough as currently formulated to handle whatever situation is on the other end of the 911 call. Now it’s up to the safety community to get ready.

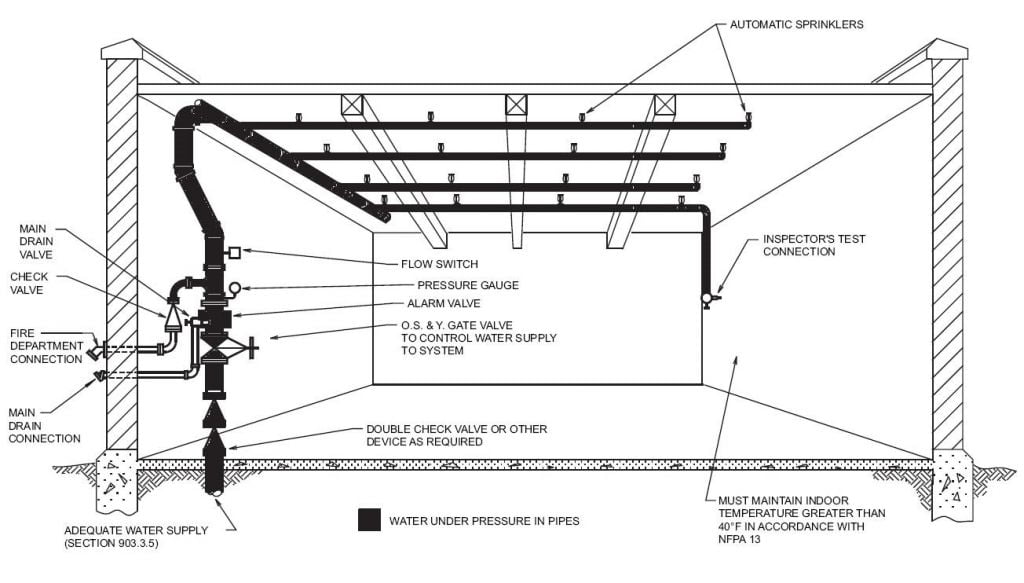

SOURCE: NFPA

PEOPLE We Protect

Our Distributors and Suppliers

Experience

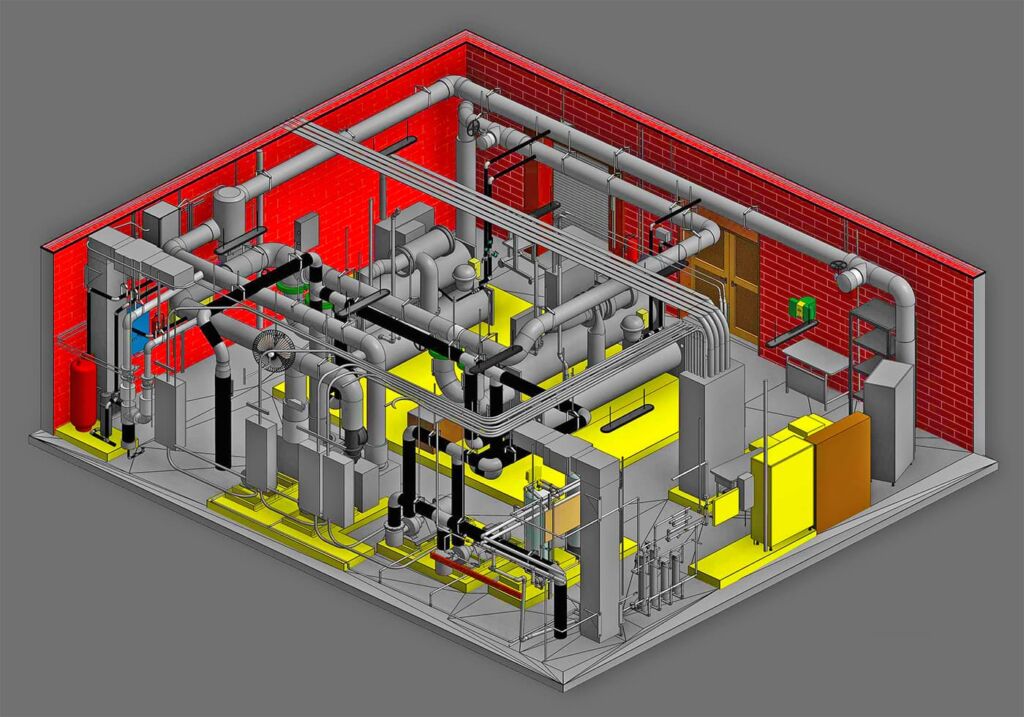

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.