Precision Fire Protection News

Stranded Energy – Electrical Vehicle Accident Response

The number of electric vehicles on the road is growing rapidly, even as critical questions remain about how to effectively respond to the most severe EV crashes

BY JESSE ROMAN

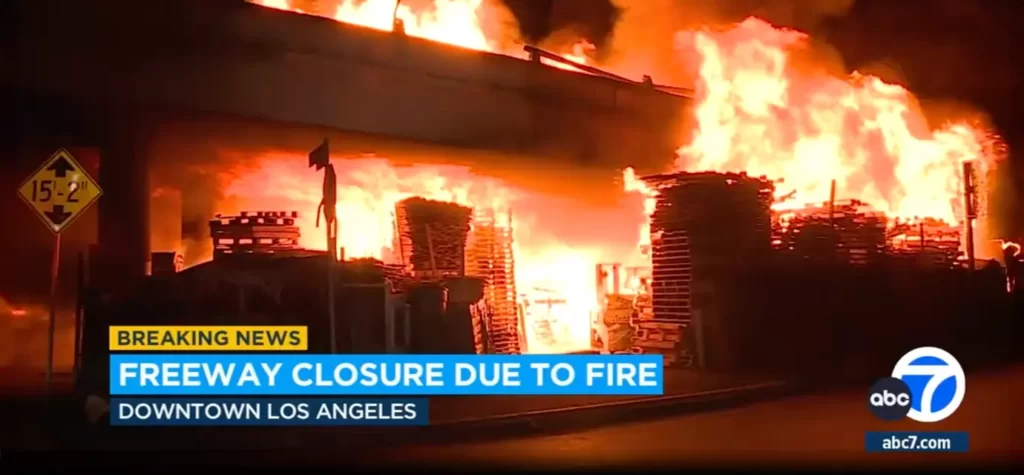

AT 9:27 A.M. ON MARCH 23, 2018, just as the morning rush hour was starting to ease in Mountain View, California, a violent collision threw a ho-hum Friday commute into chaos.

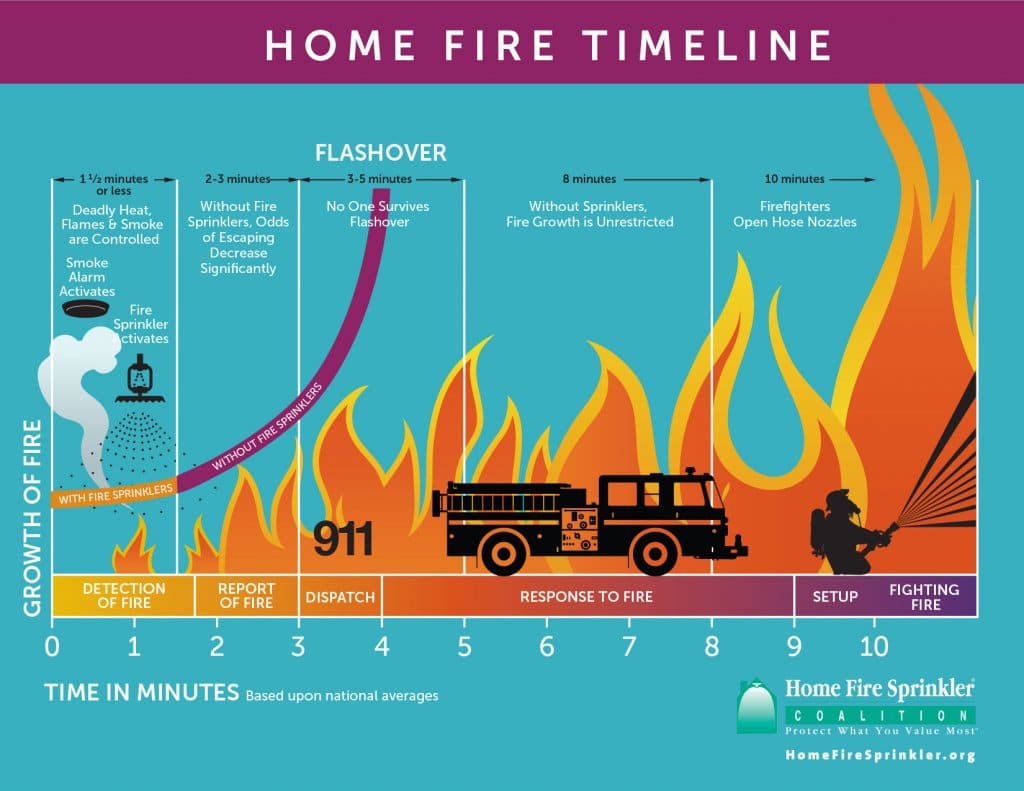

For reasons still unexplained, a Tesla Model X SUV, traveling at 70 mph down a flat, straight stretch of the 101 freeway, abruptly drifted left and slammed into a concrete median that divided the freeway from an offramp. Bystanders risked their lives to pull the 38-year-old driver from the wreck before it burst into flames. He later died at the hospital from his injuries.

The crash resulted in a complex and dangerous accident scene. The impact tore the front end off the vehicle’s frame, ripping open the Tesla’s 1,200-pound, 400-volt lithium ion battery and scattering energized cells across the road. By the time units of the Mountain View Fire Department arrived, just after 9:30 a.m., the badly damaged battery was shooting flames five feet into the air. Firefighting crews readied their gear and got to work.

If there was a fire department anywhere in the world equipped, trained, and prepared to handle the situation on the 101 that morning, it was the Mountain View Fire Department. The Bay-area city of 80,000 is in the heart of Silicon Valley and home to a who’s who of technology behemoths, including Tesla itself. Tesla vehicles are assembled nearby, and the company routinely hosts emergency responders from Mountain View and elsewhere to teach them about its EV batteries, high-voltage wires, and emergency cut loops, straight from the engineers who designed them. Tesla has donated hundreds of vehicles to local departments to practice emergency extractions and other procedures, and Mountain View’s firefighters have had plenty of live training. Nearly 10 percent of passenger vehicles in Silicon Valley are either hybrid or fully electric, double the national average, according to a recent study. “We’ve been through a lot of Tesla and other EV crashes,” Juan Diaz, chief of the Mountain View Fire Department, said in a recent interview. “I hear reports come in every day.”

As they’d been trained, firefighters shot copious amounts of water directly at the flaming battery, and extinguished the fire in a couple of minutes. After eight more minutes with no reoccurrence of fire, they turned off their hoses. But the severed battery continued to hiss and pop, sounds Diaz likened to “slamming a hand on a kitchen table.” Firefighters feared the vehicle’s frame could be energized, but they lacked tools to test it. They also lacked the proper protective equipment to handle or remove the battery’s energized lithium ion cells, and there was no way for responders to drain the massive amount of energy still clearly trapped in the unstable battery. The tow company refused to load the hissing car onto a flatbed for fear of electrocution. Firefighters found themselves in the middle of a busy freeway with a battered EV and few options for what to do next.

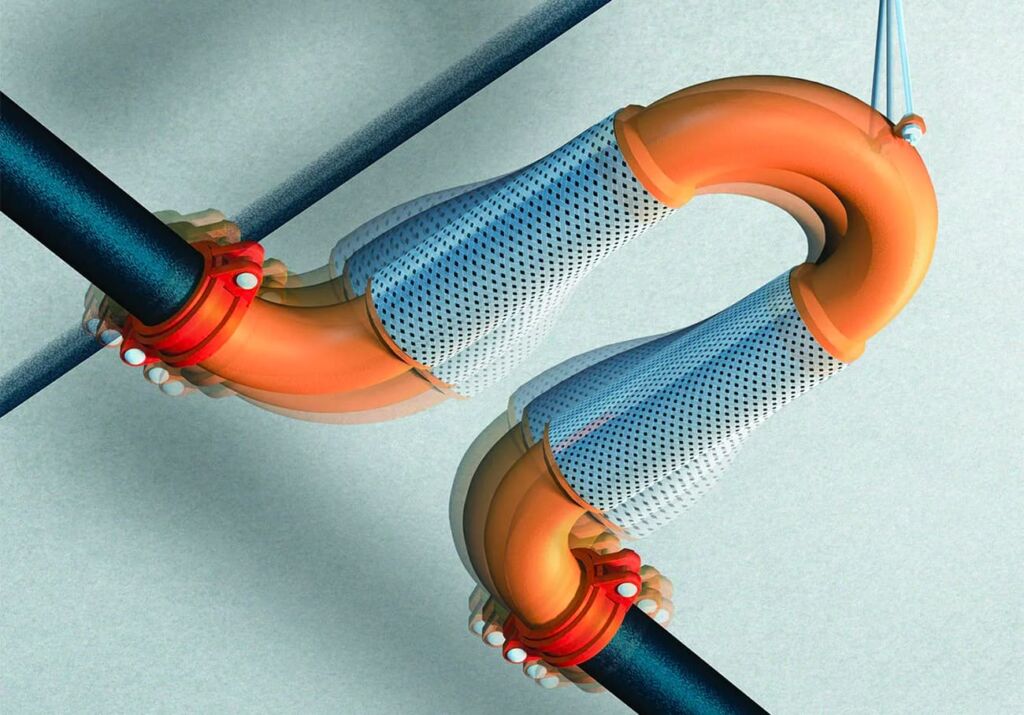

As in all Tesla models, the battery in the Model X is comprised of more than a dozen separate modules, each made up of hundreds of individual cells. All of these components are neatly packaged in a rectangular metallic case that runs the length of the chassis beneath the passenger cabin. Fully charged, the battery has a capacity of 75 kWh—roughly enough energy to power the average US home for more than two-and-a-half days, and more than enough to instantly kill anyone exposed to it. If punctured, breached, or otherwise damaged, heat can build rapidly inside the compromised battery cells and spread to surrounding cells in a cascade-like process called thermal runaway, which can lead to fire, arc flashing, off gassing, and sometimes explosions. Faced with these hazards, the Mountain View firefighters resorted to one of their few remaining options: call Tesla.

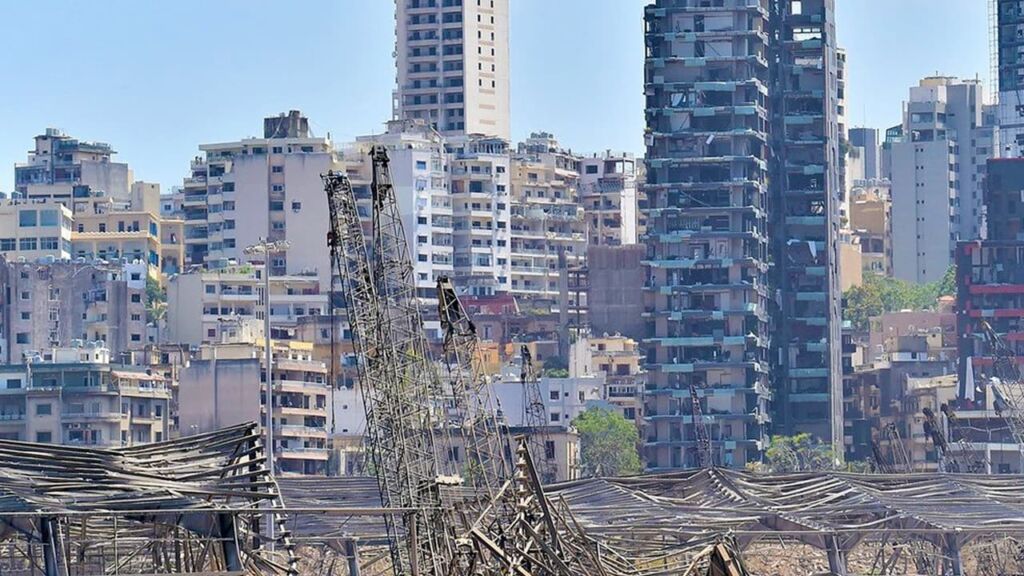

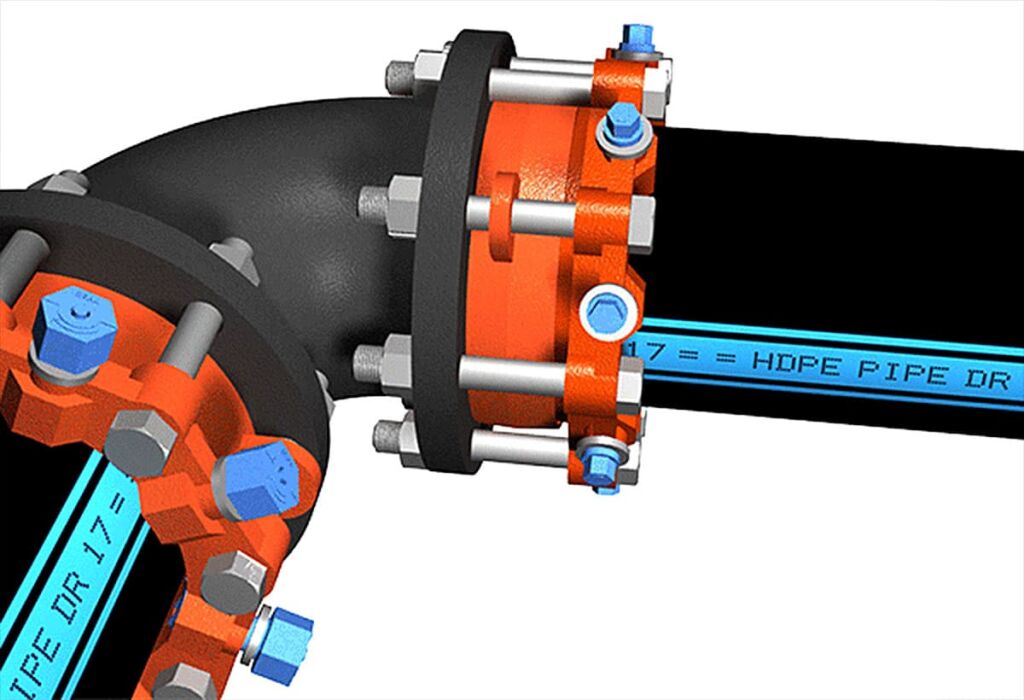

Engineers from the nearby Tesla headquarters work to clean up and de-energize exposed portions of the battery. (Mountain View (CA) Fire Department

About two hours into the event, a team of Tesla engineers arrived at the crash site, dispatched from company headquarters just down the road. The engineers began the laborious task of disassembling the damaged battery cell by cell, dropping each into a bucket of water. The six-lane 101 remained closed for six hours as Tesla employees removed the exposed portion of the battery and isolated the exposed high-voltage wiring, while firefighters provided water as necessary to keep the fire from reigniting. With about a quarter of the battery removed, it was agreed that the car was safe to transport to an impound yard in nearby San Mateo. A Mountain View fire captain and fire truck accompanied the tow on the roughly 20-mile trip. During the ride, what was left of the car’s battery continued to pop like a firecracker.

At the impound, the vehicle’s battery ignited twice within the first 24 hours, and the salvage yard operator had to call San Mateo firefighters to assist. The following Thursday, six days after the initial crash, the battery reignited yet again. Tesla engineers eventually removed the remaining battery from the vehicle and de-energized it by submerging it in a vat of salt water.

Afterward, the US National Transportation Safety Board investigator who looked into the crash told Diaz that the Mountain View department was the first he had seen to properly mitigate a battery fire under such extreme circumstances. Other than the driver of the vehicle, no further injuries or damage were reported.

Still, the crash—and dozens of others like it around the world—lay bare the gaps in our understanding of what can occur in such incidents, and how far responders have to go to prepare for the rapid influx of battery technology that experts say is fast approaching. That technology goes beyond EVs to include all manner of energy storage systems (ESS), from utility-scaled ESS arrays to consumer-sized ESS that can be stored in a home’s garage to provide electrical power on demand (see “Beyond EVs”). Right now, though, the hazards associated with EVs are of primary concern to many responders. With the number of EVs on the roads expected to rise dramatically—and with it, the number of crashes and associated challenges—emergency response experts say much more research and training are needed to provide them with tools to deal more safely and effectively with the most severe EV incidents.

The responding Mountain View crews were out of service for about seven hours for a single EV crash; a similar accident involving a combustion engine vehicle would typically take about 30-45 minutes to clear, Diaz said. If EV incidents become more common, “it will put more resources out of service and impact our ability to respond to other emergencies,” he said.

For departments outside Silicon Valley, a similar battery breach incident poses myriad additional questions beyond just a drain on resources. Chief among them: Faced with similarly extreme conditions, what should a fire department do if it can’t call in a bevy of nearby EV engineers to assist?

“Certainly, I would say from this experience that the fire service is not prepared to fully mitigate these fires,” Diaz told a group of NFPA employees during a conference call a month after the crash. “If Tesla had not come out we might have left it burning there on the freeway. We had no other choice.”

NO GOOD OPTIONS

The primary challenge faced by Mountain View firefighters that day was stranded energy, a widely overlooked issue with little scientific literature, according to researchers interviewed for this story. Stranded energy is any scenario where electrical energy remains in a battery without an effective means to remove it. This typically happens when the battery is damaged—by force, a coolant leakage, heat, or water intrusion—and normal function ceases. This can also lead to thermal runaway. How much energy remains in the battery when it’s damaged can greatly affect the severity and duration of the reaction.

There are currently no ways for responders to determine how much energy remains in a damaged battery, and no way to drain that energy to reduce the threat. The battery industry is working to improve safeguards so that thermal runaway and stranded energy are no longer issues, said Don Karner, the founder of Electric Applications Incorporated, a company that helps battery manufacturers test products and tailor them to new applications. Even with the best technology, however, Karner said, some risk will always exist, especially with batteries being used in more applications and under more extreme conditions.

“Nothing is ever perfect,” he said, especially regarding batteries in EV applications. “We are essentially taking a battery pack and throwing it down the road at 75 miles an hour and crashing it into another one coming the other way at 75 mph—the margin for error is extremely small,” said Karner, who is also chair of the committee on stranded energy for the Society for Automotive Engineering. “You never quite know if everything is going to go perfectly, so you always have a contingency if the battery catches fire.”

In addition to the Mountain View incident, dozens of similar incidents have occurred recently around the world, from New Hampshire to Moscow, where built-in battery safeguards did not work as expected. Each resulted in difficult, time-consuming cleanups for responders who, without a means to remove stranded energy from a damaged battery, had limited options at their disposal.

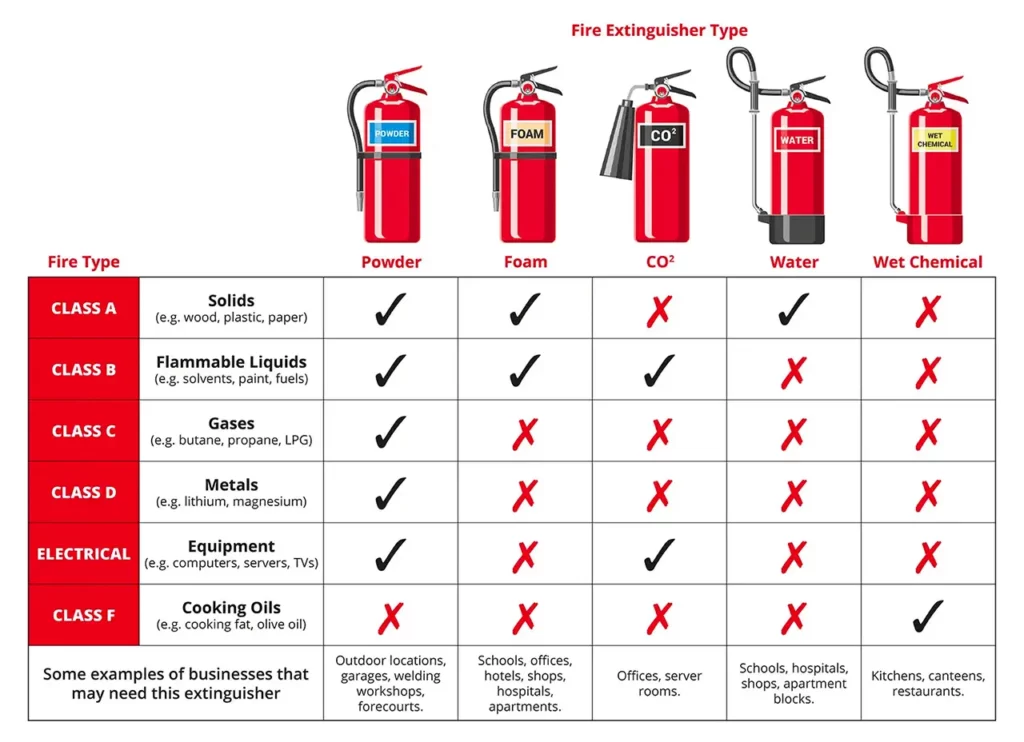

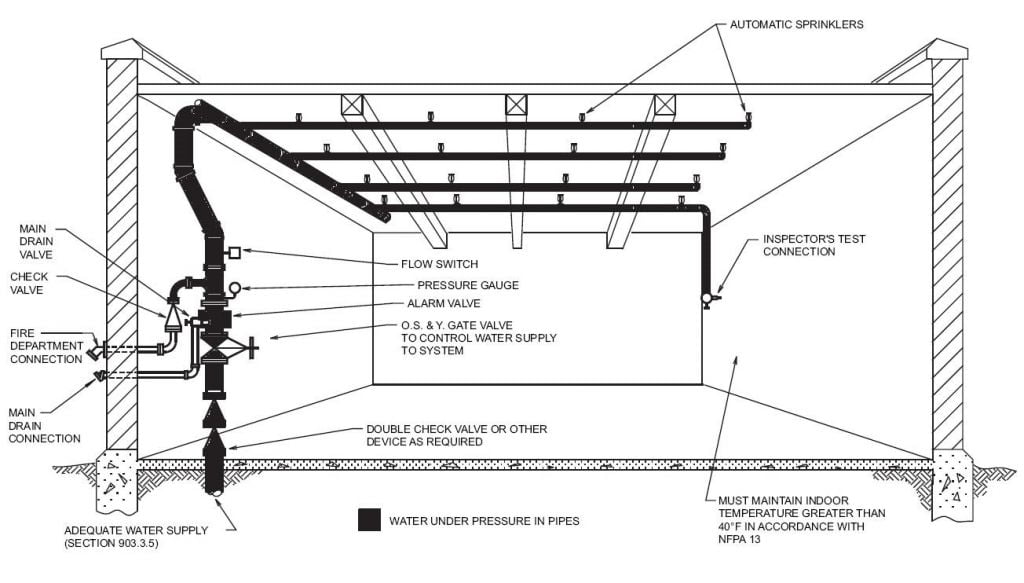

Using water to cool a damaged battery in thermal runaway is currently the dominant strategy for responders and is the tactic taught in the NFPA course on EV and battery response. Based on fire testing conducted at the request of the Fire Protection Research Foundation (FPRF), NFPA recommends that firefighters shoot “copious amounts of water” directly on the area of the battery case, and use a thermal imaging camera to periodically look for signs of heat from the ongoing chemical reaction inside the battery. However, because EV batteries are typically tucked between the vehicle’s undercarriage and passenger compartment, firefighters say it can be hard, if not impossible, to access the battery to get water on it. The inclination for some is to try and cut holes in the vehicle floor to expose the battery, said Cory Wilson, a battalion chief at the Fremont (California) Fire Department, who for several years has led trainings on emergency response in Tesla vehicles. That strategy is dangerous and counterproductive, he said.

“The Tesla battery is separated into 15 different compartments, so if you start poking holes from one compartment into another, you’re going to spread that fire quicker and further and you could actually cause damage and begin the thermal runaway process in more of those cells,” he said. Also, “if you cut into the high-voltage lines, you will be dead instantly.”

In Fremont, home to Tesla’s 10-million-square-foot production plant, the fire department has started using a special form of jack during EV fires to lift the vehicle up on its side, allowing firefighters to lob water at the undercarriage close to the battery. “We also fill up the floor pan of the vehicle itself to keep the battery cool from the top side,” he said. “Still, you’re not necessarily getting water directly on the battery itself. You’re cooling the elements around it.”

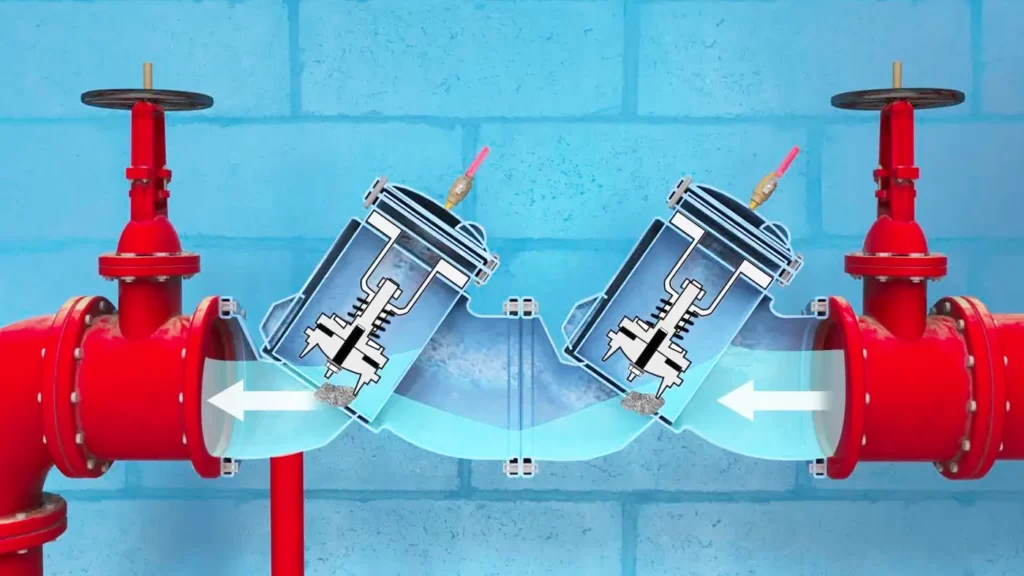

Another potential option for stopping thermal runaway is to drain the battery of the energy causing the reaction, which is much easier said than done, according to Victoria Hutchison, a research project manager at the FPRF. The typical de-energization method used by many manufacturers is to submerge the damaged battery for several days in a salt water bath until the bubbles stop, indicating that the chemical reaction inside the battery has ceased. While this tactic may seem less than ideal for first responders on a freeway who lack the technical expertise to remove a damaged battery, the lack of tried and tested options has forced them to get creative.

In the Netherlands, firefighters use tow trucks to transport large shipping containers to the site of EV accidents where a battery has been compromised. The box is filled with water, and a small crane lifts the vehicle and lowers it into the bath, where it can be safely taken away to an impound. This strategy is becoming more common across Europe, where many fire departments have already converted their ladder trucks into small cranes to help them deal with train derailments, said Wilson, who recently spoke at an EV conference in the Netherlands.

“They don’t have to worry about sitting on it for very long in case it reignites—they can load the box on a tow truck and drive it to the tow yard and it’s good to go,” he said. “But the logistics for us in the US are a little bit more difficult because most fire departments don’t have cranes. It doesn’t seem feasible.”

In the Netherlands, crews load a BMW EV into a water bath after the battery began smoking inside a car dealership last spring. (Courtesy of Central and West Brabant Fire Brigade)

Short of dropping a vehicle into a mobile tank of water, Diaz speculates that “in the future, the fire service could have tools available that we can hook up to a plug in the vehicle and transfer the energy out of the battery.” He envisions that some fire departments may have specialized EV teams that could be deployed to draw energy out of the battery, similar to how HAZMAT teams are currently trained to drain gasoline from a tank.

While some de-energizing tools currently exist, almost all of them are manufacturer-specific and only work if the battery is intact and undamaged, not split open on the highway, Hutchison said. Third-party manufacturers have made some strides to develop a universal de-energizing tool to work on any battery, but again, only if the battery is not critically damaged.

Karner is skeptical that first responders will someday have tools to de-energize damaged batteries at a crash scene. He said the technology could theoretically exist, but the feasibility is questionable.

“Draining the battery is not a matter of seconds. It’s probably not even a matter of minutes—we’re talking an hour or hours to do that,” he said. “On top of that, the list of issues just goes on and on. How do you decide if the damage is severe enough that it’s necessary to drain a battery? That will destroy the battery, so now the insurance people are probably getting involved. Who is going to be trained to do it? Do you do it at the intersection, or on the side of the road on private property? My opinion is that you move the vehicle to a place where it can be dealt with in a more orderly fashion and use some precautions along the way.”

Short of being able to drain its energy, simply knowing how much stranded energy is left in a damaged battery would go a long way toward helping responders decide what risk it poses and if it is safe for transport, Wilson said. “But we have no way of knowing what the charge level is of that battery pack when we show up on a scene,” he said.

That leaves responders, tow truck drivers, salvage yard owners, and others unsure of the potential hazard they are dealing with, Hutchison said. She called the situation “a cascading effect of risk transfer,” where a potentially lethal energy source repeatedly switches hands and yet “nobody knows the extent of that risk.”

A viable solution to that problem doesn’t appear to be on the horizon, either. According to Hutchison, even in labs with the best equipment, determining how much energy remains in a damaged battery continues to be a challenge. She tells of instances where batteries were fully burned—to the point they looked like piles of rubbish—and a couple hours later, when researchers touched the piles with a pole, they sparked. “These were professionals who had done a lot of testing on batteries, who were confident that there could not be any remaining energy in the battery,” Hutchison said. “And they were wrong.”

The challenges don’t stop even when the car has been transported to an impound. Because of lithium ion’s penchant for reigniting without warning, like a trick birthday candle, NFPA recommends that an EV with a damaged battery be stored at least 50 feet away from other vehicles and buildings. This recommendation could be tough, if not impossible, to follow in urban areas with limited space, Hutchison said. But it’s the only safe strategy at the moment.

Karner believes that, as EVs proliferate, sophisticated third-party facilities dedicated to housing and de-energizing damaged vehicle batteries after accidents will emerge to fill this need. Until that happens, however, fire departments and salvage yard operators are coming up with their own solutions. Shortly after the Mountain View Tesla crash and subsequent reignitions, Diaz issued a memo to his firefighters detailing a new strategy. Once at the tow yard, firefighters are to build a dam around the damaged EV and flood it with water, where the vehicle will sit submerged for up to three days to prevent reignition.

“The battery is going to continue to go through thermal runaway even if it’s submerged in water, but I know that if you flood it with water and isolate it so that nobody gets near it, the water’s cooling ability will not allow ignition to occur,” Diaz wrote.

THE ROAD AHEAD

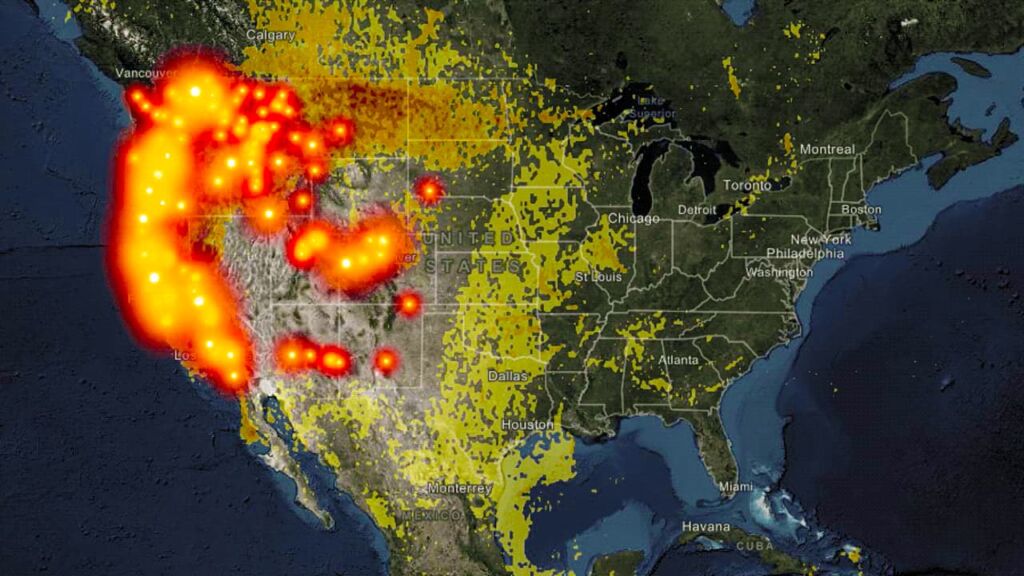

Feasible strategies to handle severe EV crashes may need to come sooner than later, because the world is about to experience a dramatic surge in the number of EVs on the road.

Two years ago, there were 3.1 million EVs worldwide, according to the International Energy Agency; by 2030, the IEA estimates the number will be 130 million. The market investment firm JP Morgan predicts that by 2025, about one in three vehicles sold across the world will be either hybrid or fully electric. The percentage of pure internal combustion engine vehicles, which have accounted for well over 90 percent of vehicles sold since the dawn of the automotive age, will drop sharply—to a 70 percent market share by 2025 and 40 percent by 2030, JP Morgan estimates.

Production of lithium-ion batteries overall is expected to follow a similar trajectory. The firm LG Economic Research Institute estimates that between 2017 to 2022, there will be an eightfold increase in production of rechargeable lithium-ion batteries of all kinds, as well as a 55 percent increase in deployments over that time.

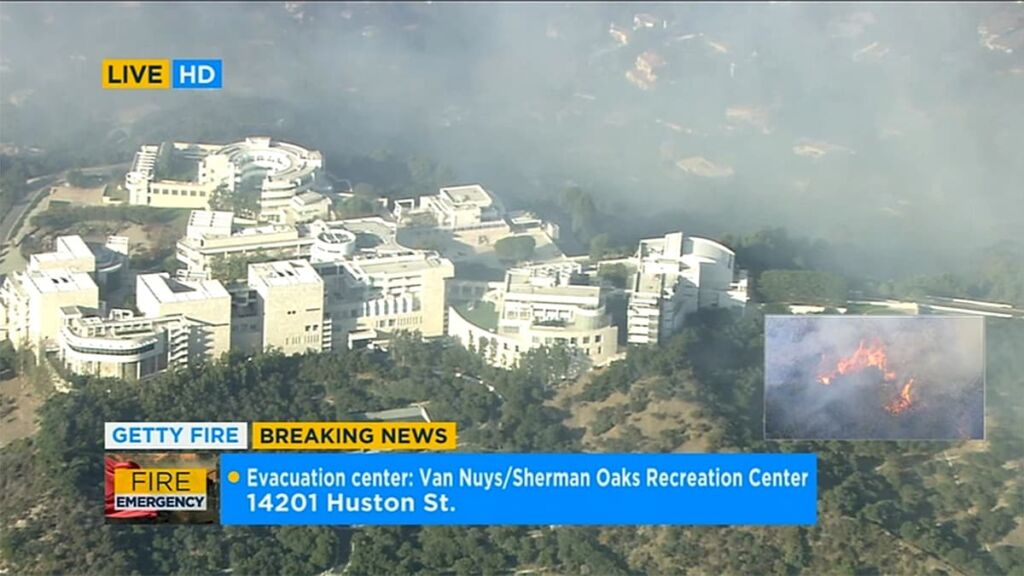

The Tesla factory in Fremont, California. The number of EVs on the road is expected to grow dramatically in coming decades. (Courtesy of Tesla)

However, cases of stranded energy are still novel enough that most people outside of the battery industry are largely unfamiliar with the challenges it poses for responders and others—including a majority of those working within emergency response. Likewise, few studies have been conducted that address stranded energy in any comprehensive way, though that may soon change. At least three major projects on the topic are now nearing completion (see “Research Powered”).

The research will likely inform the development of new battery and vehicle standards, as well as additional training programs for responders. Since 2012, NFPA has offered online alternative fuel vehicles safety training for first and second emergency responders, which covers best practices, tools, and information required to safely handle these incidents. According to NFPA estimates, roughly 250,000 of the 1.1 million firefighters in the US have received the training, which is periodically updated as more information is gathered.

Last spring, in an empty parking lot in Covington, Georgia, NFPA, the California Department of Forestry and Fire Protection (CalFire), Tesla, and a company called Advanced Extraction took part in a live burn of a Tesla vehicle. The event was an opportunity for firefighters to train and for researchers to gain new insights. Observations from the burn resulted in updates to the NFPA EV training program, which will be available early next year, according to program manager Andrew Klock.

The new material will include information on the optional tactic used in Fremont of propping the vehicle up on its side to expose the underside of the battery to water, which proved effective at the live training. Another observation, Klock said, was that newer EVs, like the one burned in Georgia, might require firefighters to use even more water than previously recommended to make sure a battery fire is fully extinguished. Whereas previous generations of Tesla batteries had a maximum energy capacity of 75 kWh, newer vehicles now on the market have options for batteries of up to 100 kWh, which allow them to travel up to 360 miles on a single charge. “With the additional energy in these batteries, we found that it took more water than in previous tests to ensure that the fire was extinguished,” Klock said.

The current training, as well as emergency field guides, emergency response guides, and safety bulletins for specific scenarios such as responding to a submerged EV, are available online at evsafetytraining.org.

In addition to building more powerful batteries, EV manufacturers have also been updating the design of their vehicles with first responders in mind—but there is still work to be done in this area. Most EV models now have an emergency cut loop, which allows responders to cut power from the main battery to the rest of the vehicle in case of a crash. The location of these cut loops varies from model to model, however, and standardization would greatly benefit responders, Wilson said. Three-sided badging to help responders quickly identify that the vehicle is an electric or hybrid is also becoming more common, but also not standardized. In addition, high-voltage lines in all EVs have been colored orange to warn responders not to touch them, and almost all manufacturers publish emergency response guides with detailed instructions on the locations of the cut switch, high-voltage lines, and other critical information.

At least one EV manufacturer has also recently made a significant design change that allows responders clear access to the battery with their hoses. After conducting several tests with firefighters, French auto maker Renault added what it calls a “firefighting access” consisting of two heat-sensitive panels opposite each other on the chassis side and the battery side. During a fire, the panels melt away, allowing direct access to the underlying battery.

Experts hope that the research being conducted now, as well as the innovations and standards that will spring from it, will inform not only first response and the automotive sector, but dozens of other industries impacted by stranded energy as batteries become more ubiquitous in nearly every facet of modern life. Karner is confident that safety institutions like NFPA, the Society of Automotive Engineers, as well as the manufacturers themselves, are up for the challenge.

“It’s a bit overwhelming when you just look at the breadth of it, but there is no doubt in my mind that at each step along the way, with each organization involved, we will have good technical solutions to the issues that arise,” he said.

For Diaz, electric vehicles and energy storage are just the next thing in a never-ending cycle for the fire service—technical advancement breeds new challenges, which are eventually dealt with and overcome. His department, in the thick of it, knows that better than any other.

“It’s just a case of the fire service playing catch-up to the modern world, just like we did back in the 1970s and 1980s with the computer and semi-conductor industries,” he said. “We live in the heart of innovation—I mean, we’ve got self-driving cars all over my city right now. And we embrace this technology. We are not against it. We think being here is exciting. But it’s not without its challenges.”

PEOPLE We Protect

Our Distributors and Suppliers

Experience

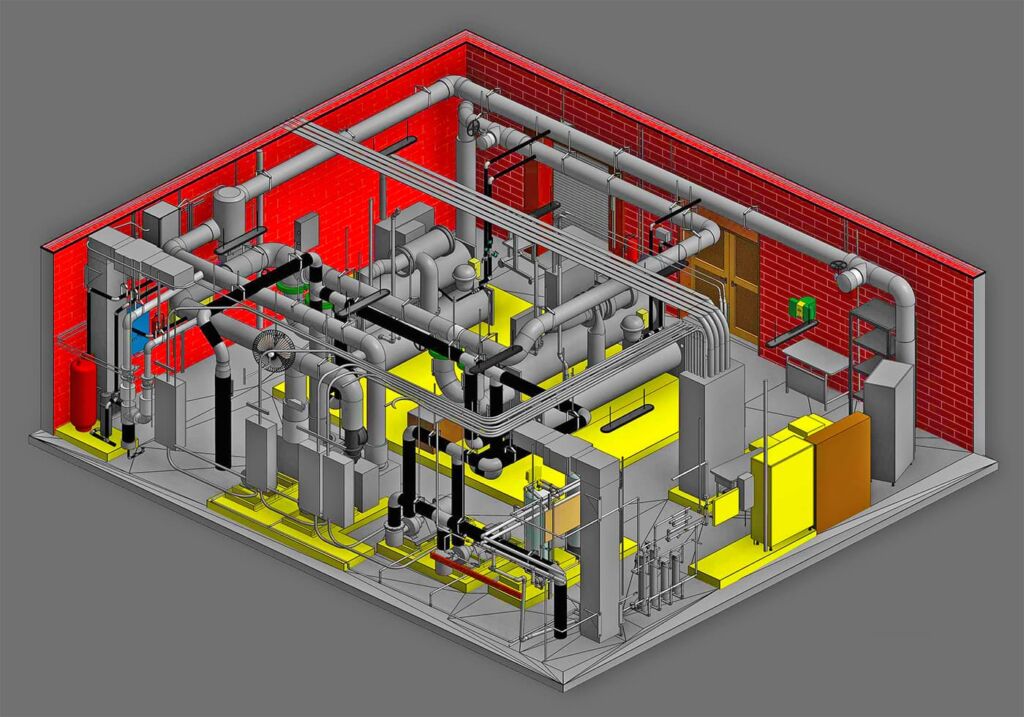

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.