Precision Fire Protection News

What Are Dry Sprinklers?

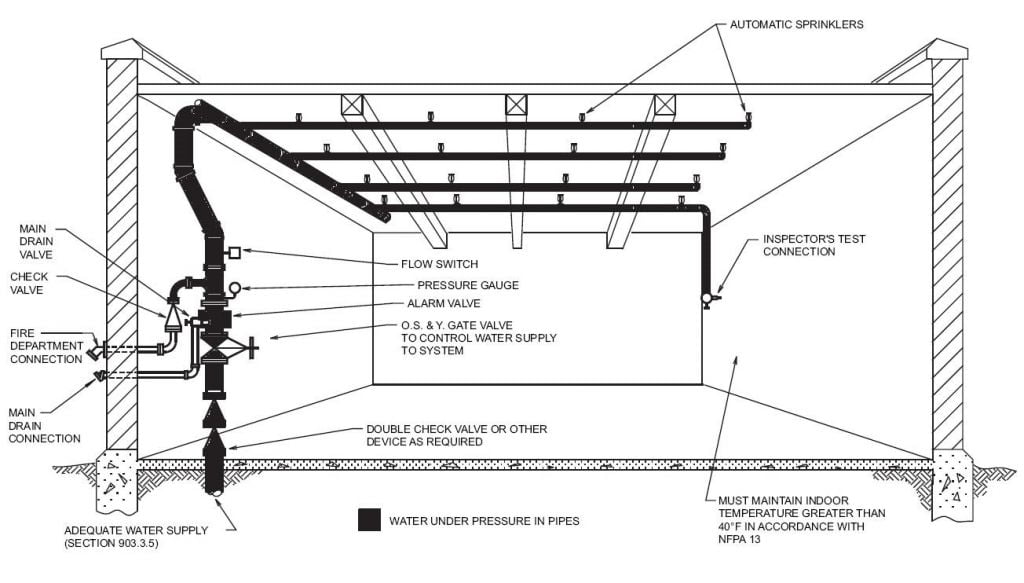

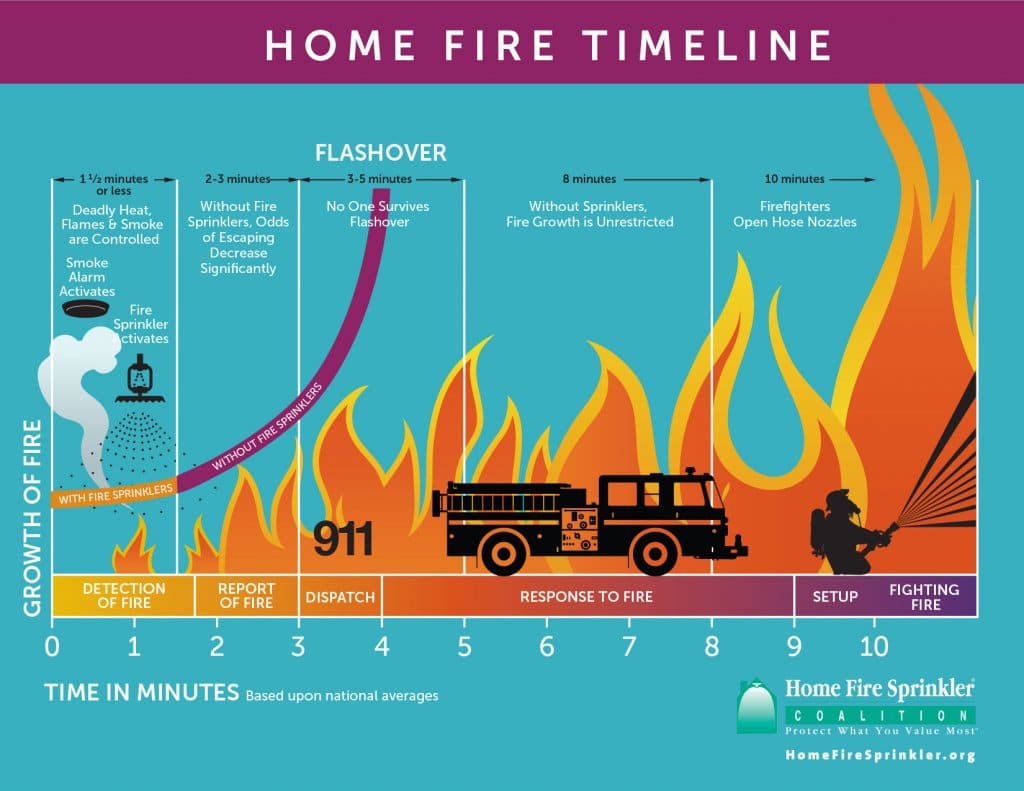

Dry sprinklers are a type of sprinkler that are able to extend into a cold space while holding the water back in a space that can be maintained at temperatures where freezing isn’t a concern. Although there are several other methods for installing sprinkler systems in areas subject to freezing, dry sprinklers allow a wet pipe system to be installed while also being able to protect ancillary areas that might be subject to freezing temperatures.

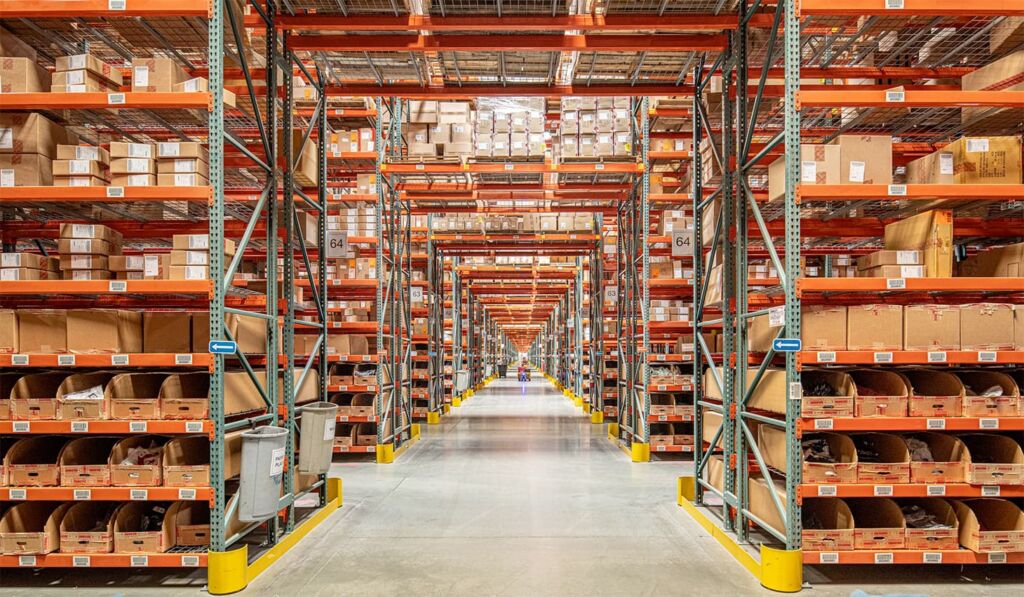

Common examples of where you might see dry sprinklers installed include loading bays or balconies that are exposed to the outside ambient temperatures and refrigerated spaces like freezer rooms.

Heat transfer basics

When thinking about how a dry sprinkler works, we need to consider some heat transfer basics. First, heat always moves from warm to cold and heat transfer occurs in three different ways, conduction, convection and radiation. Below is a brief description of each.

Conduction: Conduction is the transfer of energy within a solid, liquid or gas. In terms of dry sprinklers, this is when the cold air in the refrigerated space removes heat from the sprinkler which then removes heat from the piping. This transfer of heat from the sprinkler system into the refrigerated space is what causes the risk of water freezing within the sprinkler piping.

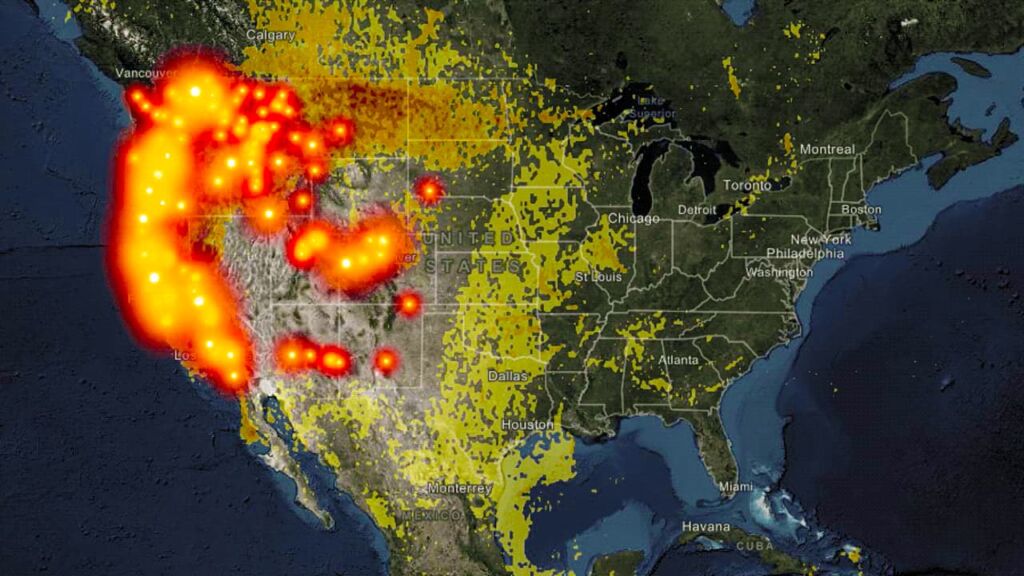

Convection: Convection is the transfer of energy between a solid surface and a moving fluid, such as air and water. This comes into play with sprinkler systems when sprinklers are installed outdoors or in other areas where it can be both cold and windy. Windy conditions increase the rate of heat transfer, meaning that the sprinkler piping looses heat to the outside air more quickly. This starts a chain reaction of heat transfer with the outside air cooling the sprinkler pipe and water inside the pipe located in the heated space loosing heat to the cold sprinkler pipe . If the wind speed increases so much that the sprinkler piping is losing heat faster than the indoor ambient air can provide heat then there is a risk of the water in the pipe freezing.

Radiation: Radiation is the exchange of energy through electromagnetic waves. Think of this as the sun heating up the interior of your car hotter than the outside air. That extra heat comes from radiation. This doesn’t often come into play when dealing with sprinkler systems, but if the sprinklers are in an area heated by the sun during the day, the risk of freezing may increase overnight when the sun goes down.

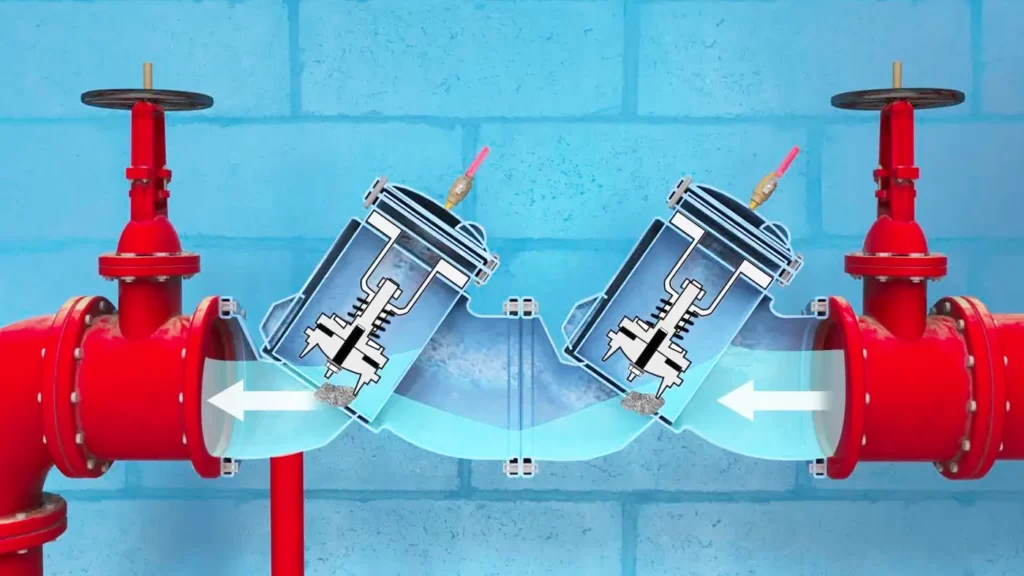

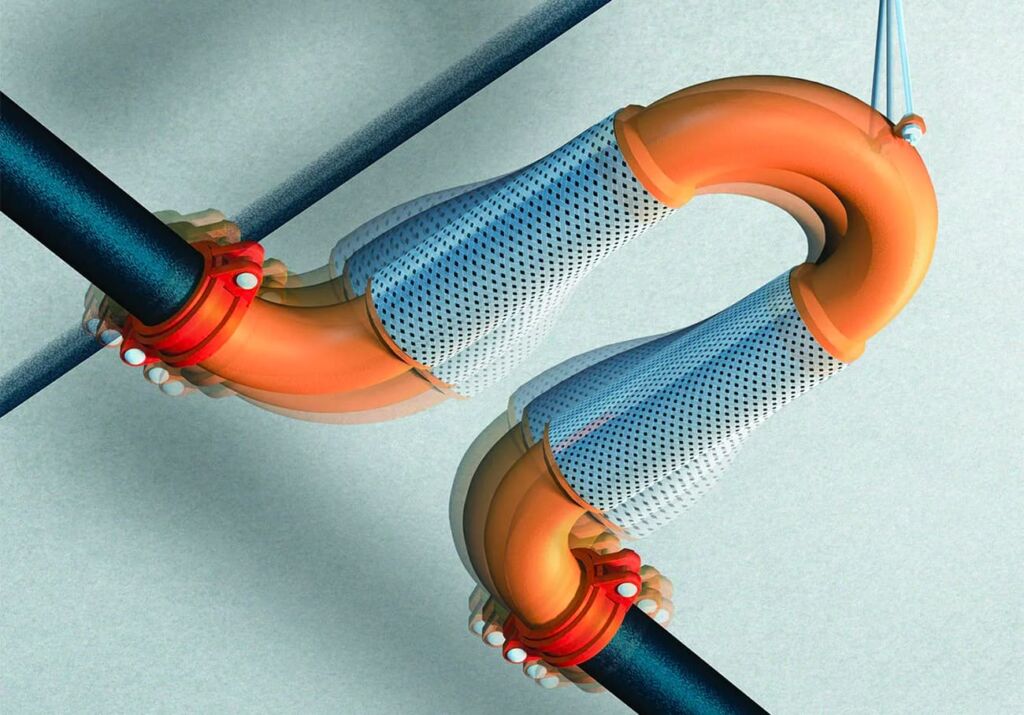

How does a dry sprinkler work?

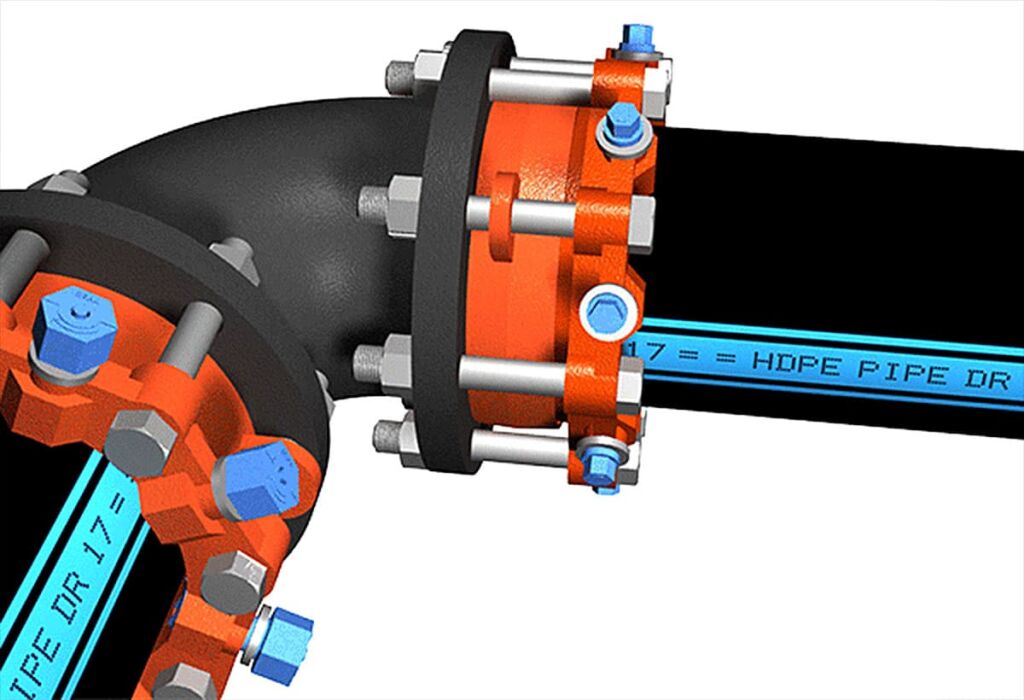

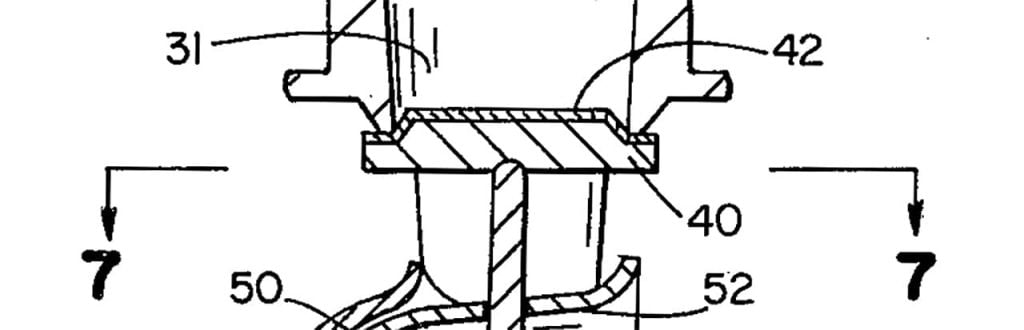

Dry sprinklers work by preventing water from being within the part of the sprinkler piping that will be exposed to cold temperatures. If you are familiar with how a dry fire hydrant works, this is very similar to that. Dry sprinklers include a portion of piping (often referred to as the barrel) where the water will be sealed off from until the heat element in the sprinkler operated and releases air which in turn releases the seal, allowing water to flow through the orifice of the sprinkler and impact the deflector to discharge on the fire.

Under certain ambient conditions, wet pipe systems having dry sprinklers can freeze due to heat loss by conduction. Therefore, due consideration should be given to the amount of heat maintained in the heated space, the length of the pipe in the heated space, the temperatures anticipated in the non-heated space and other relevant factors.

Installation requirements for dry sprinklers

Dry sprinklers must be long enough to avoid freezing the water-filled pipes due to conduction along the barrel. To ensure the barrel of the dry sprinkler is long enough NFPA 13 contains the following table in Chapter 15 (2022 edition) which gives the minimum exposed barrel length based off of the temperature that the discharge end of the sprinkler will be exposed to.

Dry sprinkler manufacturers have minimum required lengths to ensure that the dry sprinkler is properly installed and that the point of attachment to the wet pipe sprinkler system will be properly protected against condensation, freezing, and ice plugs. While dry sprinklers are available in many different lengths for various applications where used in conjunction with a wet pipe sprinkler system, care should be taken to ensure that the minimum required lengths are met based on the manufacturer’s recommendations and the expected exposed temperature. For example, in a freezer application, where the branch line can be located directly above the freezer, it might be necessary to elevate the branch line to ensure that the minimum distance is maintained between the cold region and the point of connection to the wet pipe system. It is the length of the barrel exposed to warm air that is important, not the overall length of the dry barrel sprinkler.

Ultimately sprinkler systems can be configured in a number of different ways and it is the job of the engineer/designer is to try and make it as efficient as possible. Sometimes this means using dry sprinklers to prevent the water inside of the sprinkler piping from freezing but this isn’t the only method available. Other options include:

- Dry pipe sprinkler systems,

- Preaction sprinkler systems,

- Heat tracing on sprinkler pipe,

- Listed anti-freeze solution.

Whatever method you are using, it is important to understand that there are options out there and that each one of those options has specific design criteria and unique installation requirements that need to be followed to meet the indented objectives. Dry sprinklers may be an effective way of achieving this for ancillary spaces included in a wet pipe system. For more information on the different types of sprinklers, sprinkler systems and other methods for protecting your sprinkler system from freezing check out the following blogs:

- Options for Installing Sprinklers in Areas Subject to Freezing

- Types of Sprinkler Systems

- Types of Sprinklers

SOURCE: NFPA

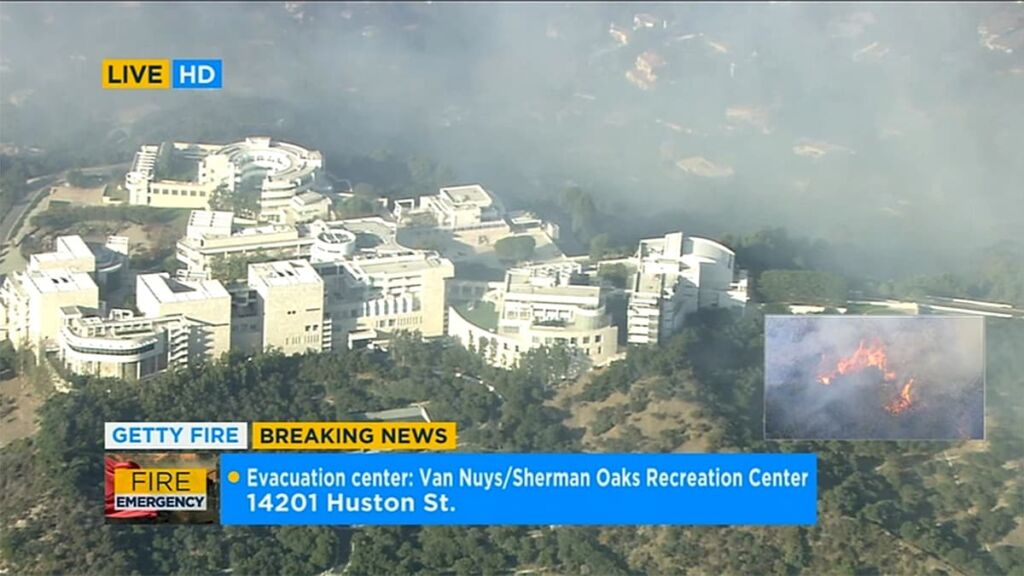

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

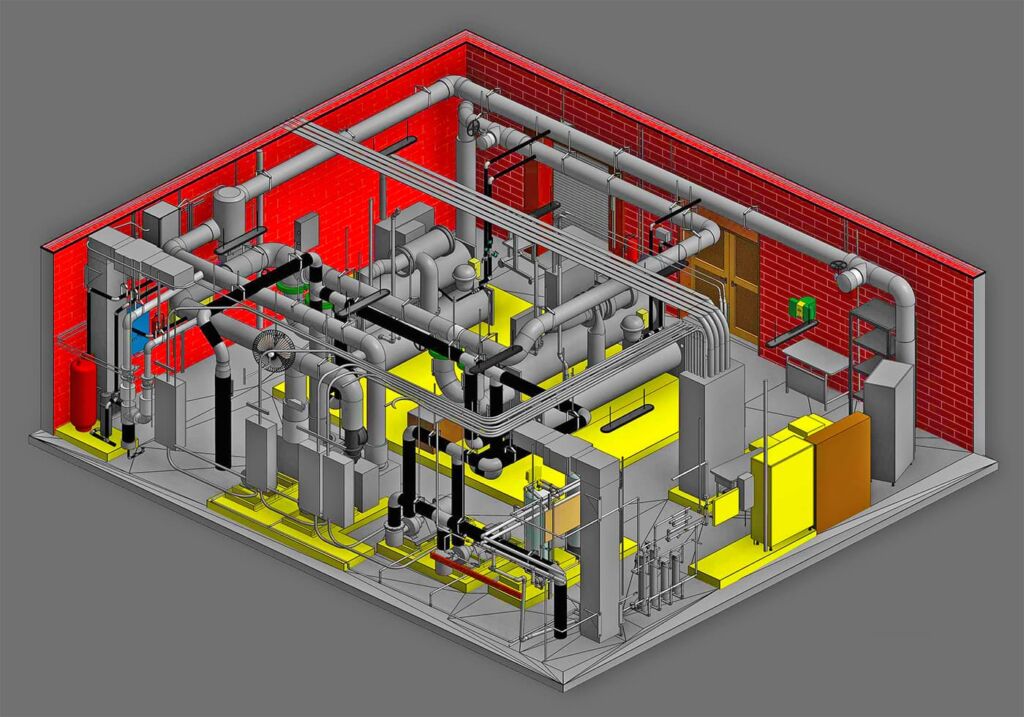

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.