Precision Fire Protection News

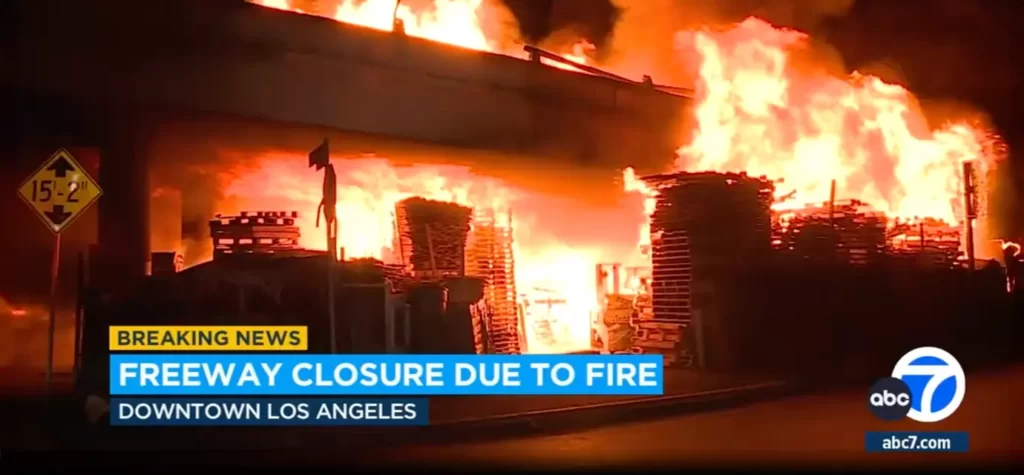

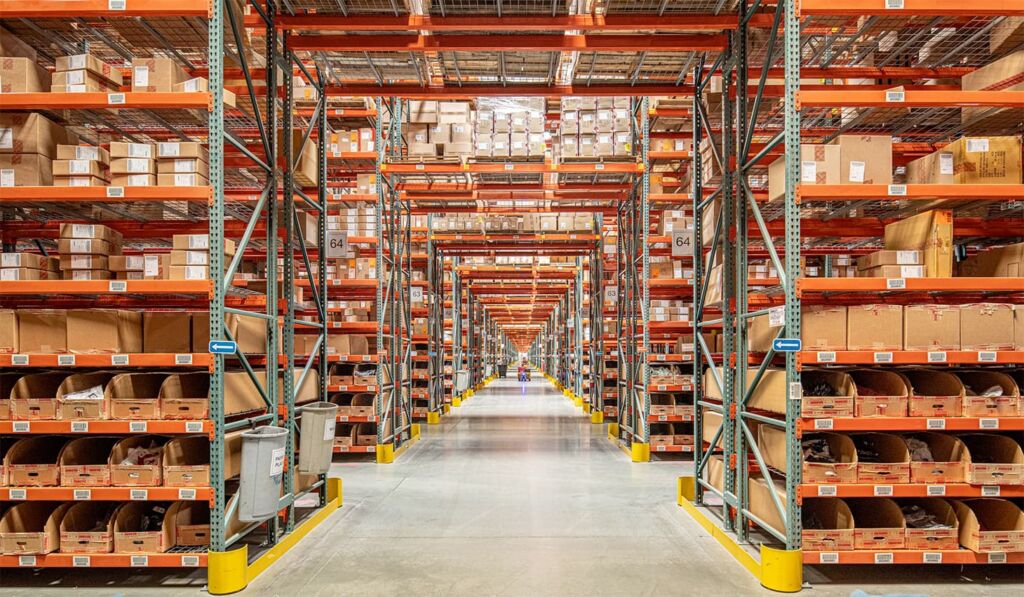

Pallet Storage Fire Hazard

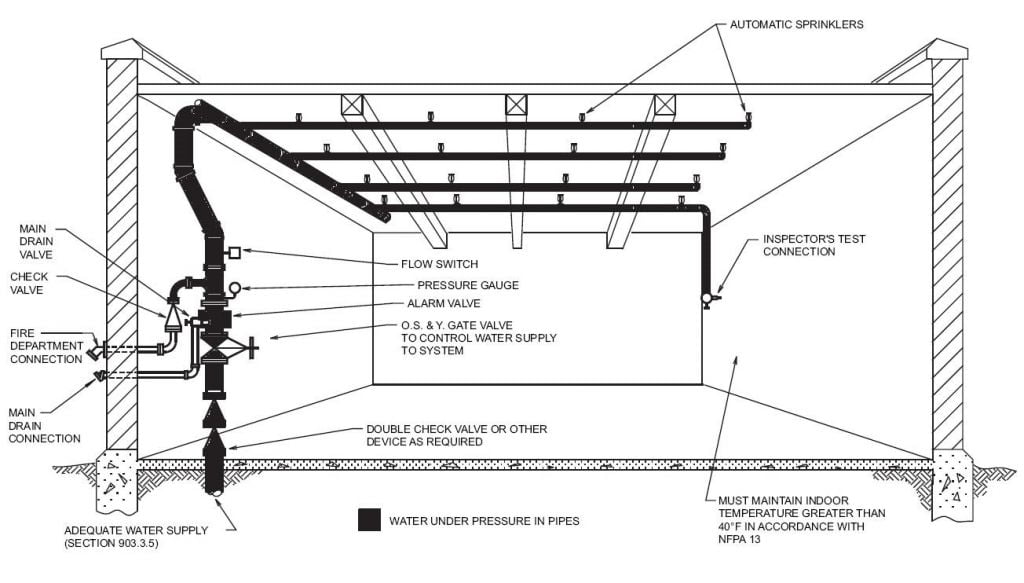

When thinking about automatic sprinkler protection for a warehouse, one might start by asking themselves, what will be stored in the building? That will define the fire hazard. This is a great starting point, but it’s also important to ask yourself additional questions: What type of operations will take place in the building? Will the owner have the need to store any idle pallets?

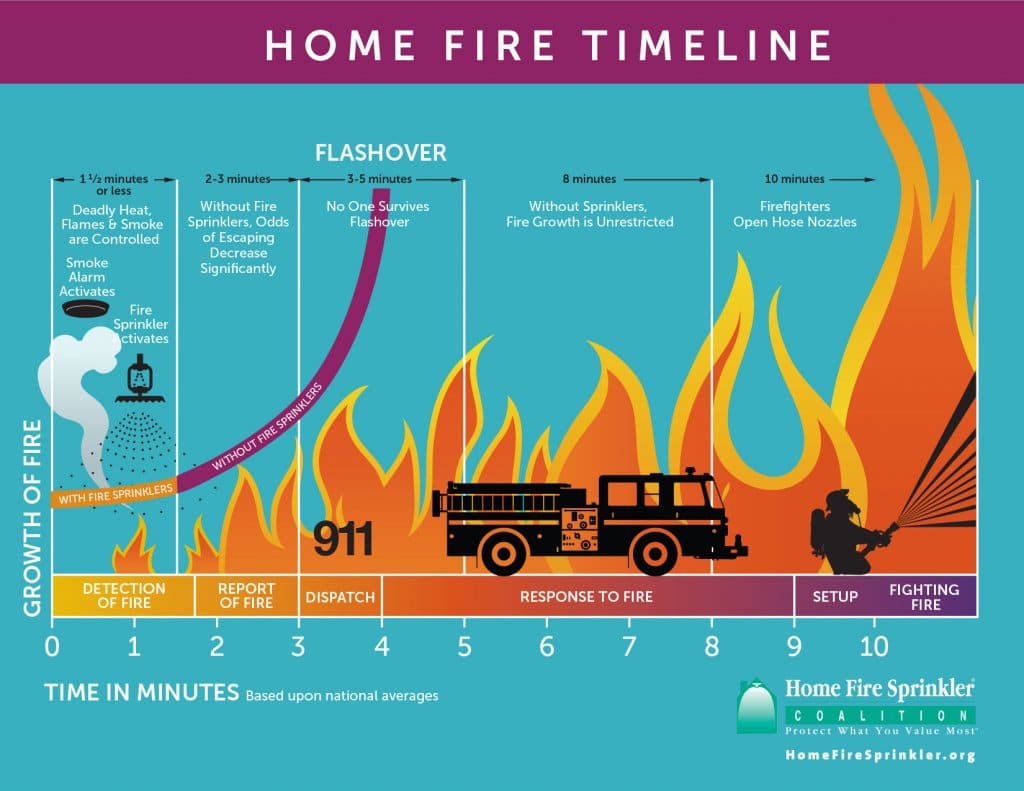

Although the latter may seem like an odd question, pallets can be a significant fire hazard—at times even greater than the commodities stored in the building. Not considering the hazard of idle pallets may result in an automatic sprinkler system that will not be effective at controlling a potential fire within the building.

Pallet fires have been shown to release large amounts of energy and challenge the effectiveness of automatic fire sprinkler systems. Stacked pallets provide airflow spaces that can optimize fire spread, while the upper pallets shield the lower ones, allowing what could be a concealed fire to rapidly develop. This type of fire is a challenge for even a well-designed sprinkler system. The 2022 edition of NFPA 13, Standard for the Installation of Sprinkler Systems, has criteria specifically for idle pallet storage in section 20.17, which is based on the type and storage arrangement utilized. It is important to note that idle pallets are treated separately from the other types of stored commodities and low-piled storage in NFPA 13.

Idle pallet storage is not limited to warehouses either. It can be a concern anywhere goods are received in bulk and broken down for sales or distribution. This may include buildings such as big-box stores, grocery stores, distribution centers, factories, and even smaller stores like pharmacies and convenience stores. Let’s review the types of pallets and configurations covered in NFPA 13 and some of the schemes provided for automatic fire sprinkler system design.

Types of Pallets

Pallets can be either constructed from wood. NFPA 13 defines a wood pallet as “a pallet constructed entirely of wood with metal fasteners,” while the standard defines a plastic pallet as “a pallet having any portion of its construction consisting of a plastic material.”

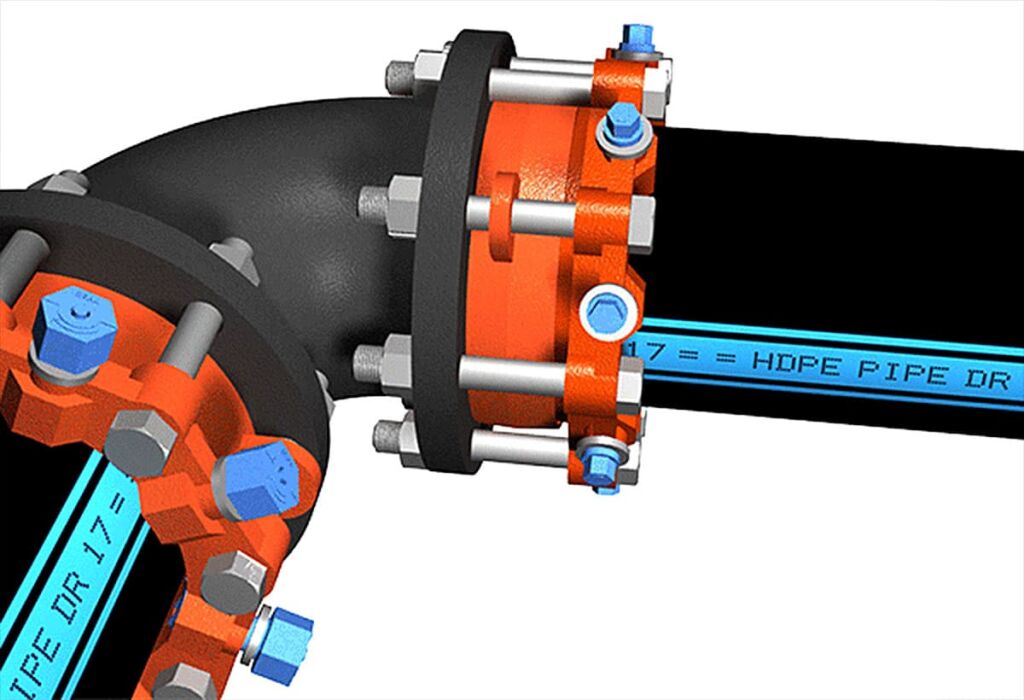

The images below are examples of wood and plastic pallets. For the purpose of automatic fire sprinkler design, plastic pallets can be treated equivalent to wood pallets when it’s been demonstrated their fire hazard is equal to or less than that of wood pallets and they’ve been listed for such equivalency.

Storage Arrangements

Although NFPA 13 recognizes idle pallet storage can occur outside, in a detached building, or indoors, the standard only provides protection criteria for indoor pallet storage. In this case, pallets can be arranged in stacks on the floor and on racks without solid shelves. The height of the pallet “pile,” separation distance from other “piles,” and the height of the ceiling are all a part of the storage arrangement and will play a role in identifying the correct protection scheme. It should be noted that the storage of idle pallets on solid-shelf racks is not permitted due to the difficulty in extinguishing idle pallet storage combined with the shielding of the shelves.

Protection Schemes

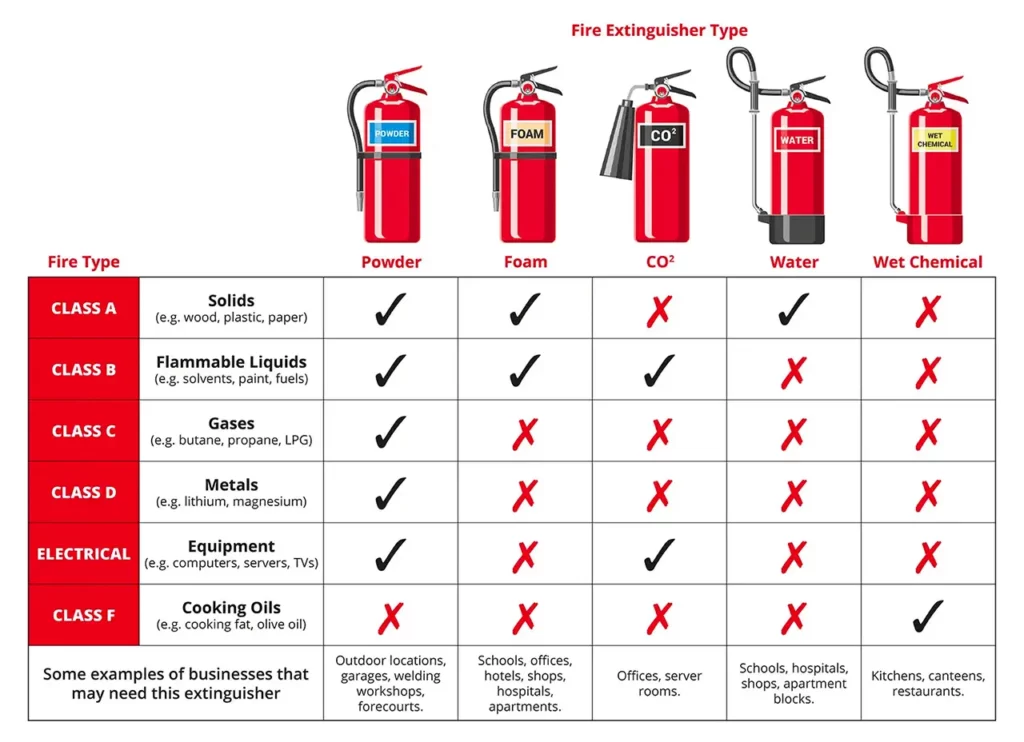

Density Area Method – Ordinary Hazard Group II

When designing the sprinkler system for protection of idle wood pallets, it’s important to remember both wood and plastic pallets can be stored inside and protected by a density/area design criteria equivalent to Ordinary Hazard Group II. For wood pallets, the pile cannot be more than 6 ft (1.8 m) in height, and for plastic pallets, the pile cannot be more than 4 ft (1.2 m) in height. In both cases, the piles must be separated by a minimum of 8 ft (2.4 m) of clear space or 25 ft (7.6 m) of stored commodity. Each wood pile is limited to four stacks and each plastic pile is limited to two stacks. This scheme allows occupancies such as department stores and small factories the ability to store idle pallets in limited quantities.

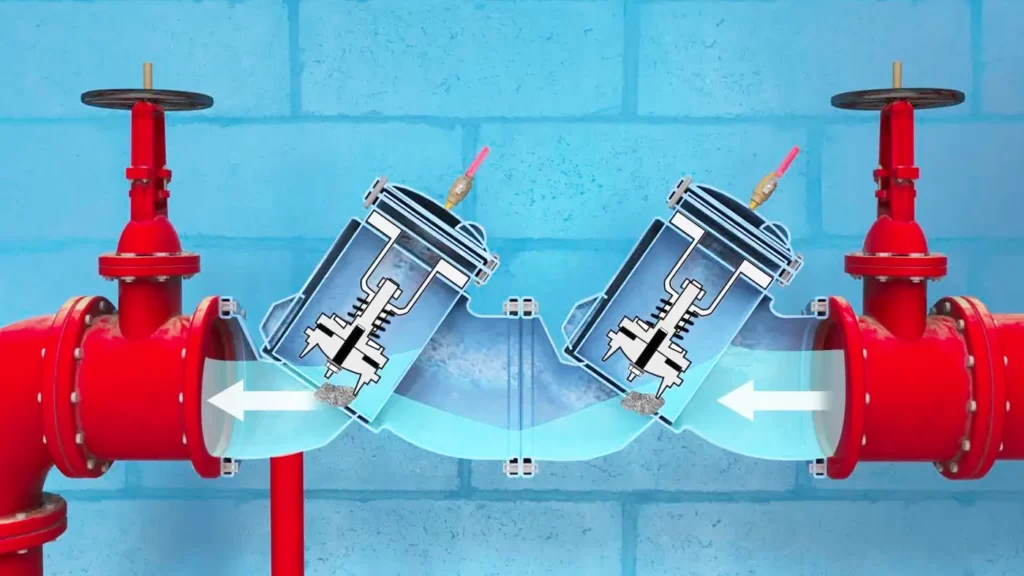

Control Mode Density/Area Method

The protection schemes for wood pallets using the density/area method allow storage heights between 6 ft and 20 ft (1.8 m–6.1 m), with maximum ceiling heights up to 30 ft (9.1 m), utilizing 0.2 gpm/ft2–0.6 gpm/ft2 (8.2 mm/min–24.5 mm/min) over areas between 2000 ft2–4500 ft2 (185 m2–450 m2). When plastic pallets are not separated in a dedicated storage room, the piles can be up to 10 ft (3.0 m) in a building, with a maximum ceiling height of 30 ft (9.1 m) and a density of 0.6 gpm/ft2 over 2000 ft2 (24.5 mm/min over 185 m2), utilizing a minimum K-factor of 16.8 (240).

Control Mode Density/Area Method – Dedicated Room

Plastic pallets are permitted to be stored in a dedicated room separated from other storage by a 3-hour-rated fire wall with storage piles up to 12 ft (3.7 m) utilizing a density of 0.6 gpm/ft2 (24.5 mm/min) over the entire room and protection from the steel columns in the room. Wood pallets do not have the same protection scheme equivalent.

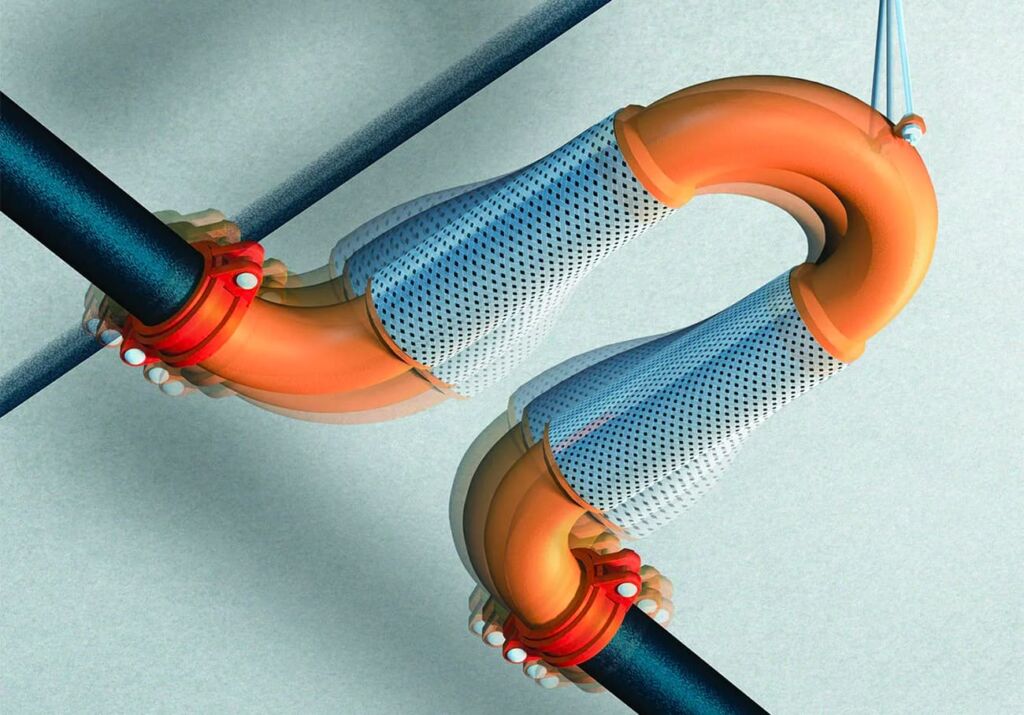

Control Mode Specific Application (CMSA) Sprinklers

Only wood pallets may be protected using the control mode specific application (CMSA) method. Pallet storage can be up to 20 ft (6.1 m) in height, with maximum ceiling heights between 30 ft and 40 ft (9.1 m-12.2 m). The range of available K-factor designs is 11.2–19.6 (160–280) with different criteria for minimum design pressure and number of heads in the design. Currently, storage on racks without solid shelves is not permitted with the CMSA design scheme.

Early Suppression Fast Response (ESFR) Sprinklers

Early suppression fast response (ESFR) sprinklers are designed for challenging fires, which makes them an option for idle pallet storage. NFPA 13 has protection schemes for wood pallet arrangements, both on the floor and on racks without solid shelves, at storage heights from 20 ft–35 ft (6.1 m-10.7 m), with maximum ceiling heights between 30 ft–40 ft (9.1 m-12.2 m), utilizing K-factor designs from 14–25.2 (200–360) and minimum operating pressures between 15 psi–75 psi (1 bar–5.2 bar). The schemes for plastic pallets are not limited in storage height, but are limited in maximum ceiling height, with schemes up to 40 ft (12.2 m) in height, utilizing K-factor designs from 14–25.2 (200–360) and minimum operating pressures between 35 psi and 75 psi (1 bar–5.2 bar).

High Expansion Foam

For plastic pallets stored in a dedicated room separated from other storage by a 3-hour-rated fire wall with storage piles up to 12 ft (3.7 m), a high expansion foam system combined with a sprinkler density of 0.3 gpm/ft2 (12.2 mm/min) over the entire room and protection from the steel columns in the room can also be utilized.

Specific Test Data

Recognizing the significant fire challenge of idle plastic pallet storage, any protection scheme that is based on test data is not only permitted but encouraged to take precedent over the listed protection schemes. However, this same clause does not exist for the protection of idle wood pallets.

Summary

The storage of idle pallets is a significant fire hazard. When this hazard is not considered during the automatic fire sprinkler system design, the potential exists for a significantly undersized sprinkler system. Whether you’re designing a warehouse or simply a storage/loading dock in an office building, it is important to consider the storage of idle wood pallets in the design. The type of pallets, height of the pallet piles, and ceiling height all influence the available protection schemes. If you’re looking for more information on sprinkler system design in storage occupancies, check out the NFPA 13 Storage Protection Requirements and Assessment (2022) Online Training Series.

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

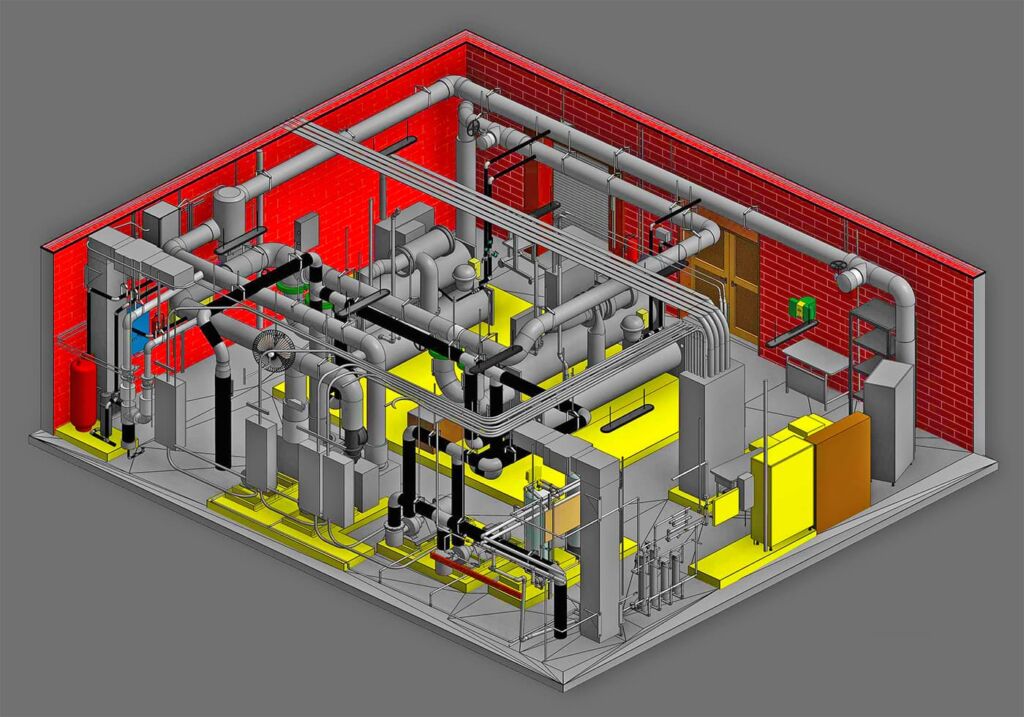

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.