Precision Fire Protection News

The Need For Underground Restraints For Sprinkler Systems

In a recent report, NFPA regional representatives highlighted underground restraints as an element of sprinkler systems that they commonly see done incorrectly. This can have a detrimental impact on the entire system, and fixing the problem after something goes wrong can be costly in terms of both money and time. It is essential that underground restraints are done correctly the first time to ensure the protection of property, the safety of occupants, and the overall success of the project.

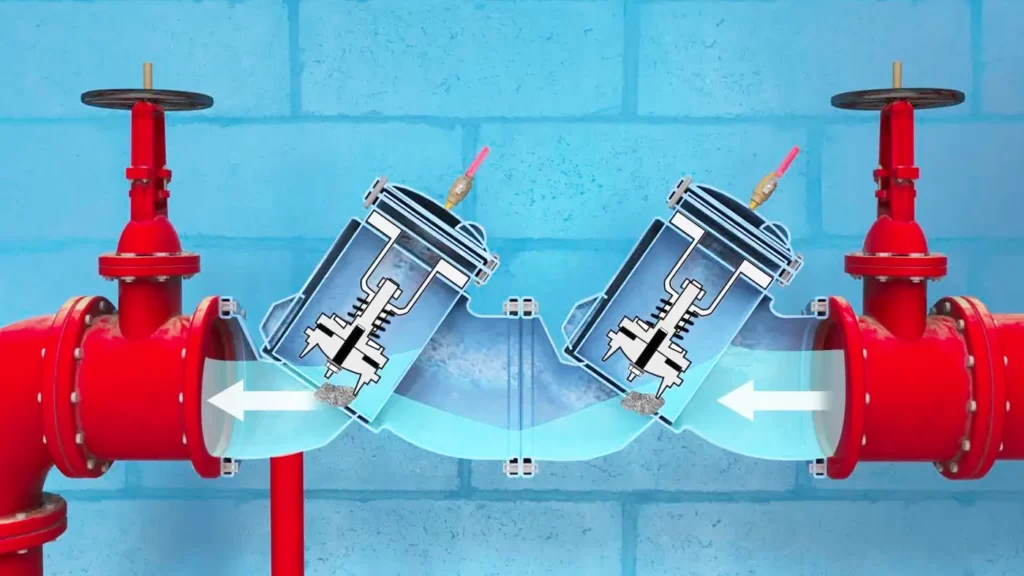

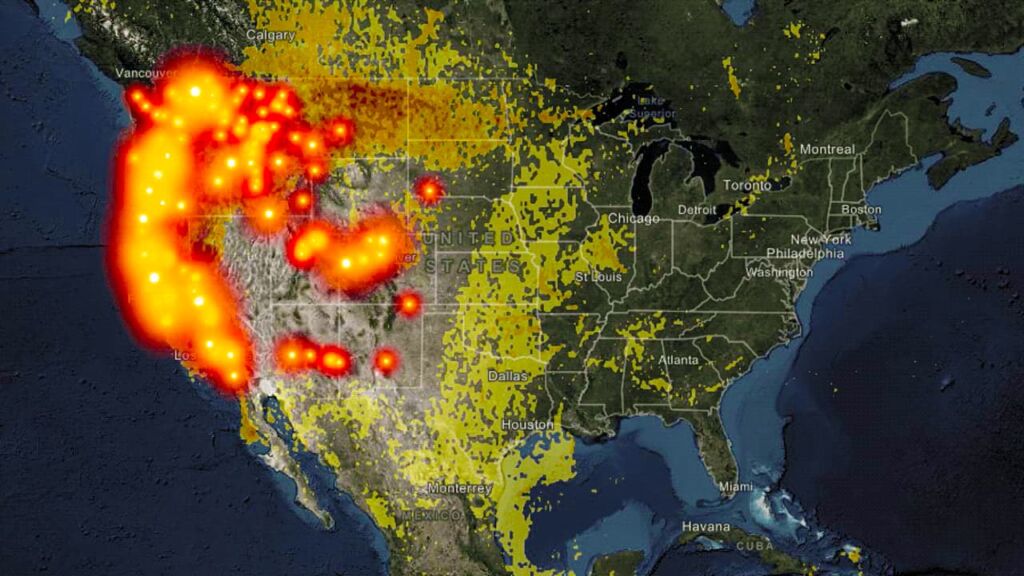

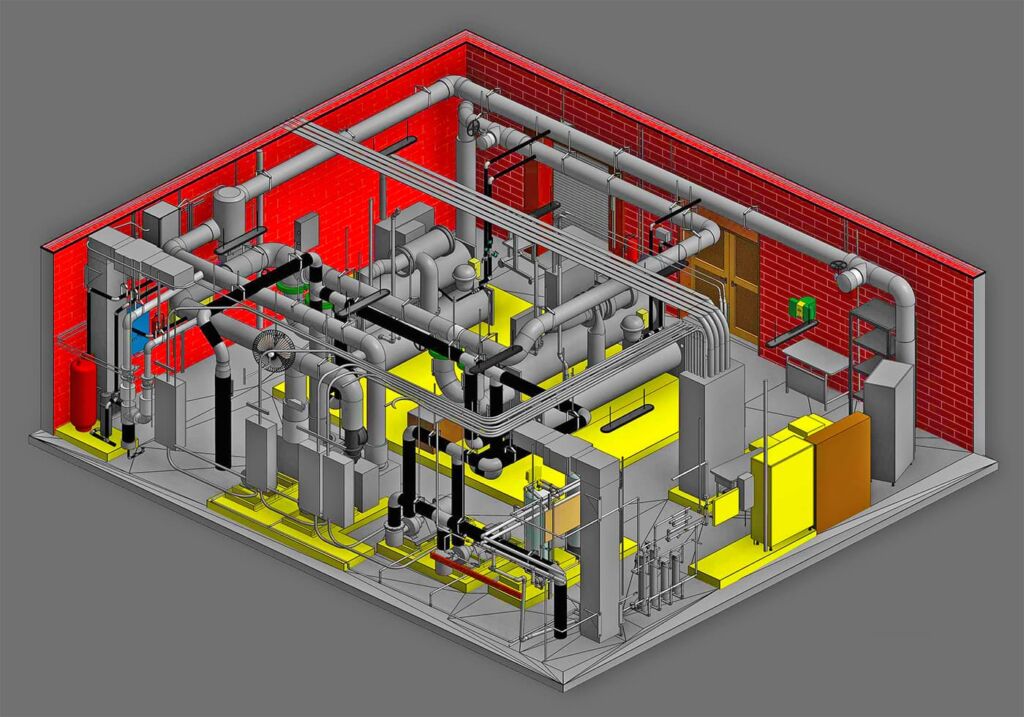

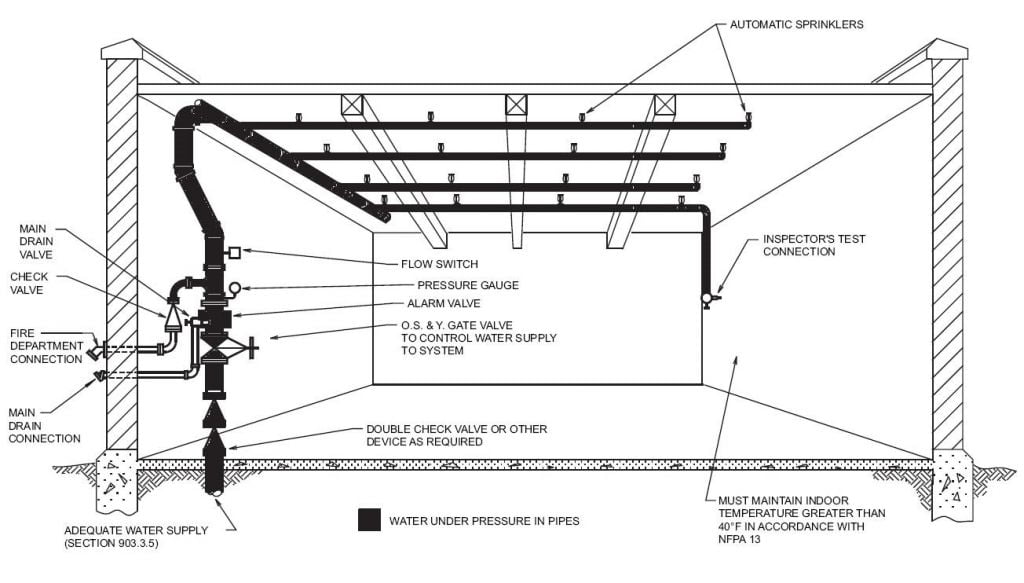

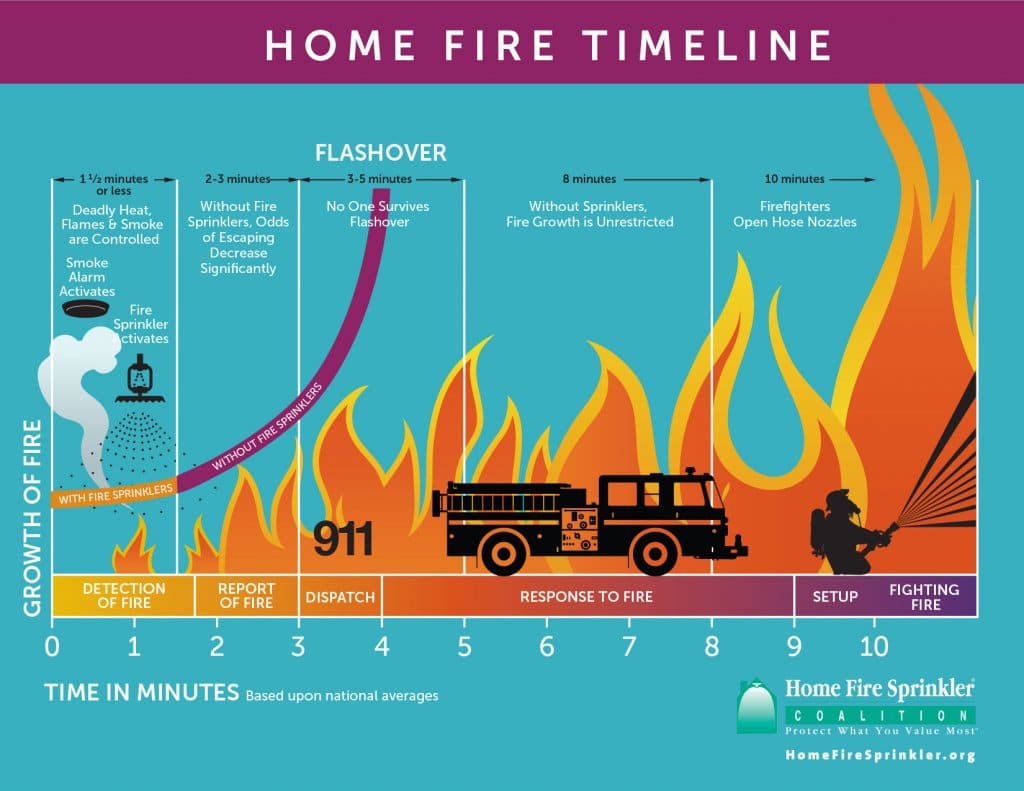

Sprinkler systems need to be dependable and ready to activate at a moment’s notice. The use of private, underground piping leading from a municipal water supply or privately owned waterworks system is one of the most common methods of supply to automatic sprinkler systems. For this system to work, the underground piping that delivers water to the system must be dependable, and must be able to resist underground pipe separation with the use of restraints.

Pipes need to be restrained against movement caused by hydraulic pressure or dynamic thrust forces created by water changing direction as it flows through the pipe. Think about cornering while driving a car, when the force pushes you toward the outside of the turn. The same phenomenon occurs when water makes a turn as it travels through a pipe, except that the force acts against the pipe joints.

Designers typically have three primary options to draw from to address this problem: thrust blocks, self-restraining fittings, or other special connections. Thrust blocks are blocks of concrete that are installed against underground pipe fittings and fan out in the direction opposite the thrust force until the surface area is several times larger than that of the fitting. Resistance is provided by transferring the thrust force to the soil through the larger bearing area of the block. Provided there are stable soil conditions and adequate space, concrete thrust blocks can be an effective method of restraining pipes, and have the added benefit of using affordable materials commonly found at a construction site.On the other hand, thrust blocks can require more time to install because the concrete needs to set.

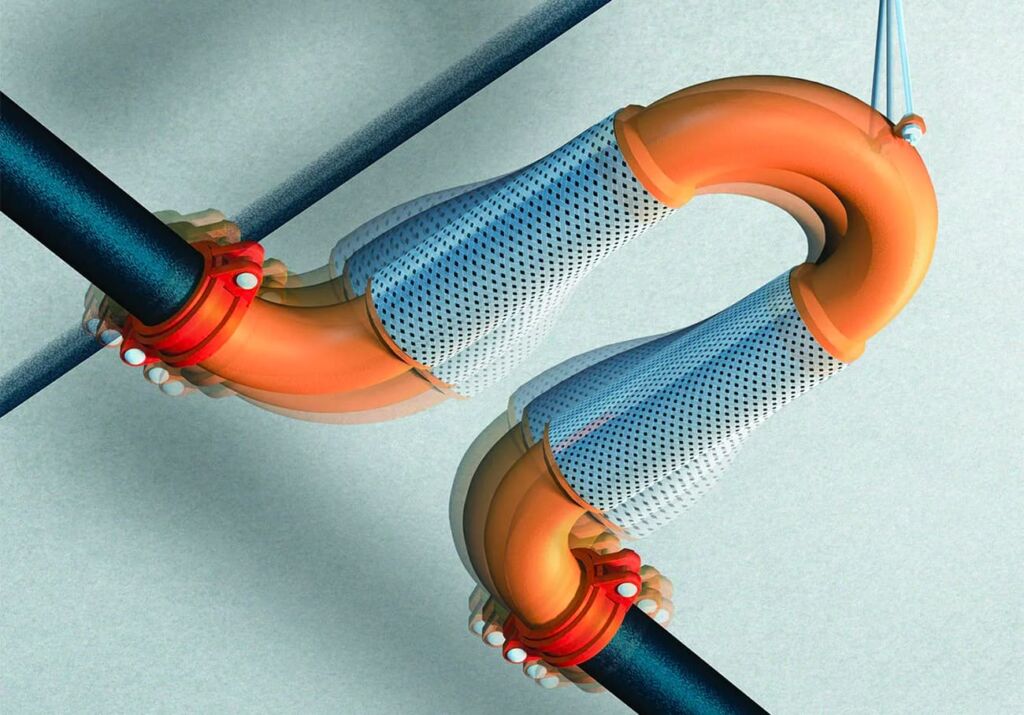

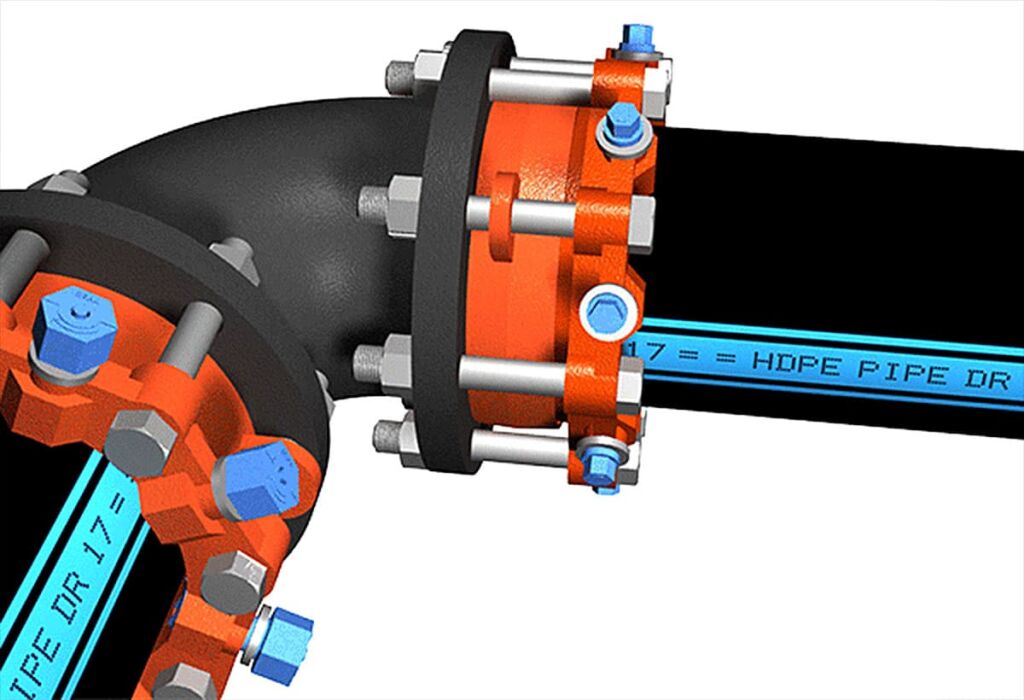

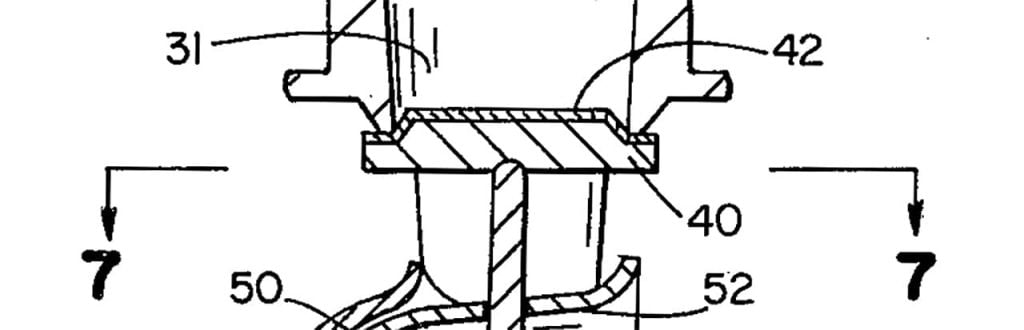

A restrained joint is a special type of joint designed to provide longitudinal restraint. This method functions in a similar manner to thrust blocks because the restrained unit of piping with the soil balances the thrust forces. Some examples of these systems include locking mechanical joints, bolted flange joints, and pipe clamps with tie rods. NFPA 13, Standard for the Installation of Sprinkler Systems, contains requirements for the material and sizing for these methods. Compared to thrust blocks, restrained joint systems are typically faster to install.

Finally, designers could also use connection methods that inherently restrain piping against thrust forces. These connection types include threaded, grooved, welded, or heat-fused connections, as well as chemical- or solvent-cemented connections. Using these connections does not require additional restraints as long as the joints can pass a hydrostatic test that is part of the acceptance testing for underground piping.

One of these methods needs to be used at points where the piping direction changes, such as elbows, bends, and tee fittings, to prevent unrestrained pipe joints from separating and to prevent pipe movement in soft soil. NFPA 13 doesn’t mandate which method should be used—the decision is left to the designer or the owner. Determining which piping connections require restraint is as easy as identifying the connections that change a pipe’s direction. Straight runs of underground pipe do not require restraining because force on a straight connection doesn’t act in a way that could separate the piping as easily.

These requirements aren’t just for sprinkler systems—they can be applied to any water-based fire suppression system. Requirements for these systems are found in NFPA 13 and are extracted from NFPA 24, Standard for the Installation of Private Fire Service Mains and Their Appurtenances. Check with the AHJ as well as local and state regulations to determine if any additional requirements apply to your specific installation of underground pipe.

SOURCE: NFPA

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.