Precision Fire Protection News

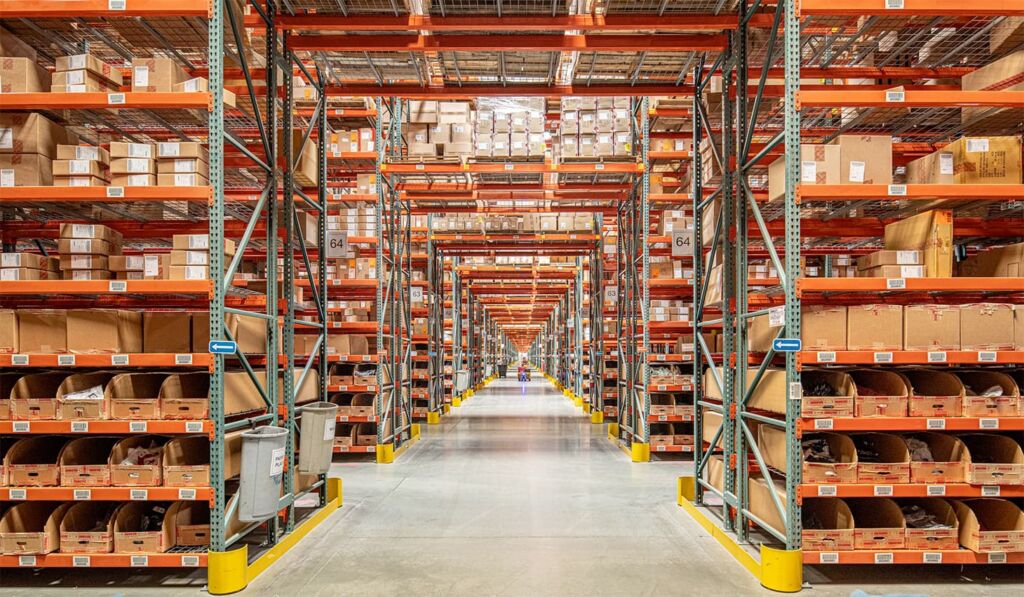

Unique Fire Protection Challenges Found in Warehouses and Distribution Centers

Unique Fire Protection Challenges Found in Warehouse/Distribution Centers

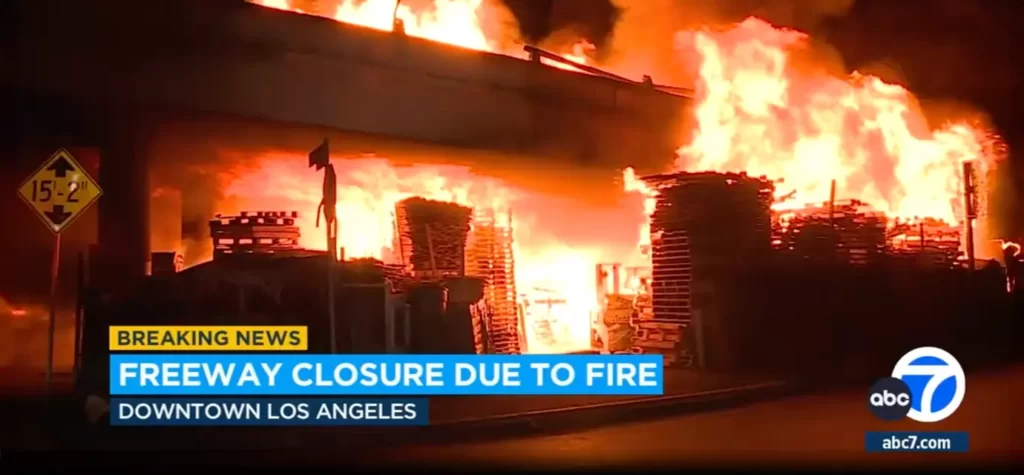

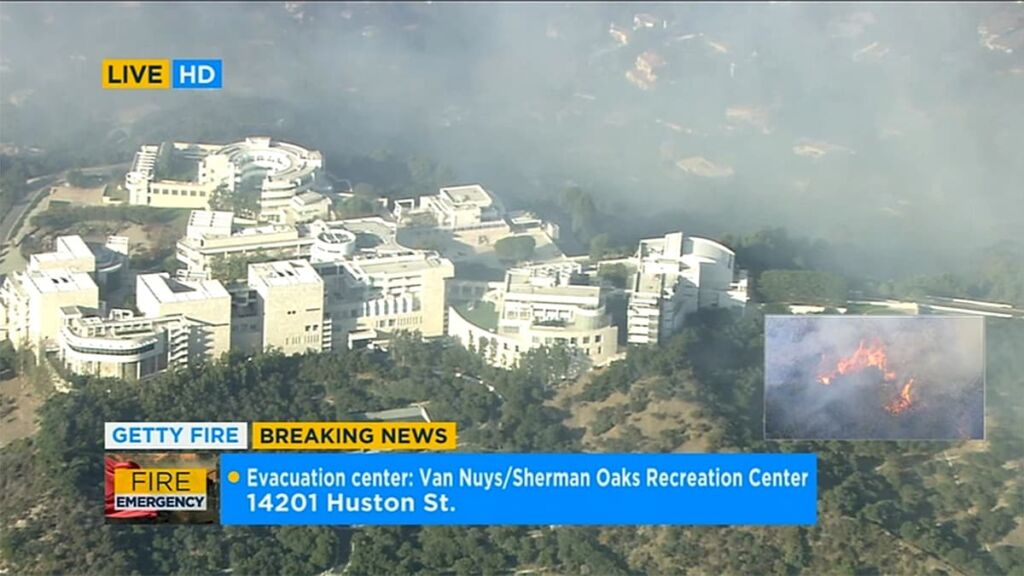

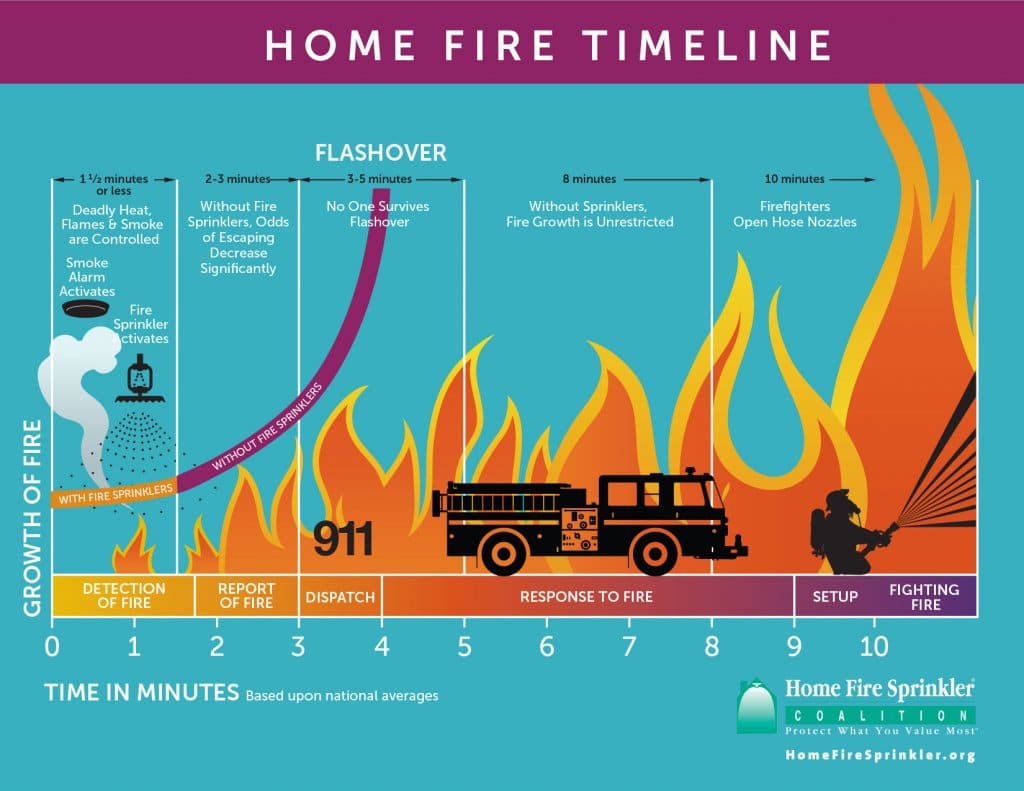

NFPA research shows that warehouse fires happen at a frequent rate with an average of 1,410 warehouse fires, two deaths, 20 injuries, and an estimated $159.4 million in direct property damage annually. To avoid becoming part of these statistics it is essential that a fire protection system is correctly designed, installed, inspected, maintained, and tested.

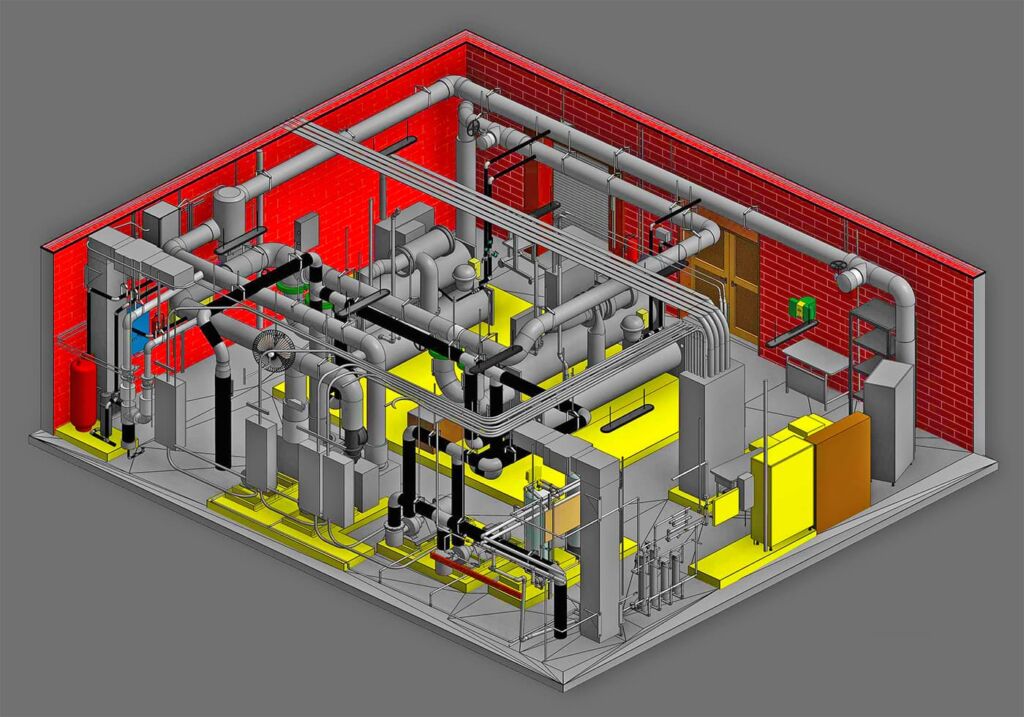

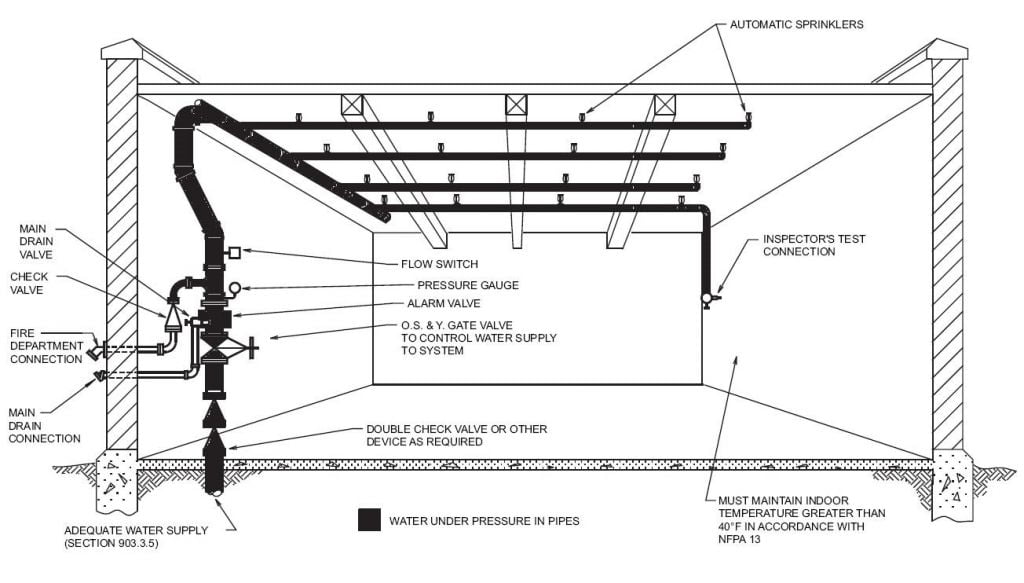

Warehouse environments require additional considerations for sprinkler system design. This is due to the nature of how warehouses are designed and used. This blog will look at a handful of unique fire protection challenges found in warehouses and other distribution centers. For more specific information on how to design a sprinkler system see NFPA 13, Standard for the Installation of Sprinkler Systems.

Commodity classification

The most obvious unique characteristic of a warehouse is that the purpose of the building is to store a large number of goods and products. This can increase the fire load by a significant amount. This is why it is essential, when designing an automatic sprinkler system for a warehouse, that the items being stored are assigned the proper commodity classification. When determining the commodity classification, it is important to include not only the product itself but also the packing material as well as the container and pallet. The different commodity classifications are as follows:

Class I – a noncombustible product that is either stored in single layer cardboard boxes or shrink wrapped or paper wrapped. The product can either be stored with or without wooden pallets.

Class II – A noncombustible product stored in either wooden crates or multiple-layered cardboard boxes. The product can either be stored with or without wooden pallets.

Class III – A product made from wood, paper, natural fibers, or Group C plastics. This can be stored with or without wooden crates and pallets.

Class IV – A product that can be made from a mixture of Group B plastics with wood, paper, natural fibers or Class C plastics. The product is allowed to be made from a small percentage of Group A Plastics

Group C Plastic – Certain plastics such as PVC. This is treated the same as a Class III Commodity

Group B Plastic – Certain plastic rubbers such as silicone. This is treated the same as a Class IV commodity.

Group A Plastic – The most flammable plastics and natural rubbers. This group is further subdivided into expanded or nonexpanded plastics. This is treated differently from all other commodity classifications.

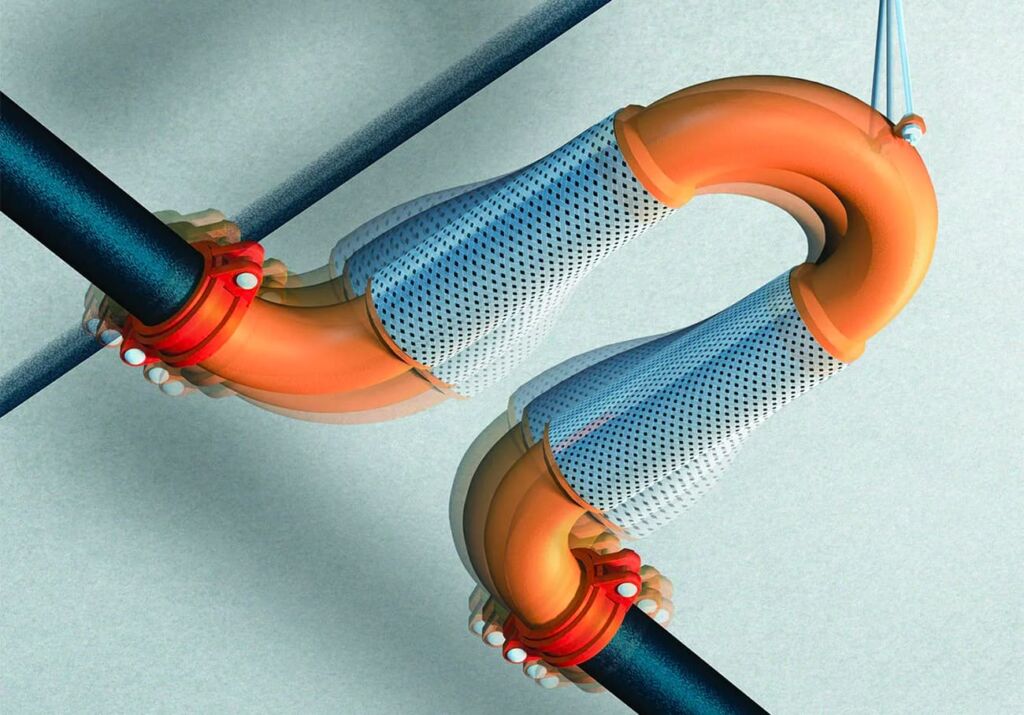

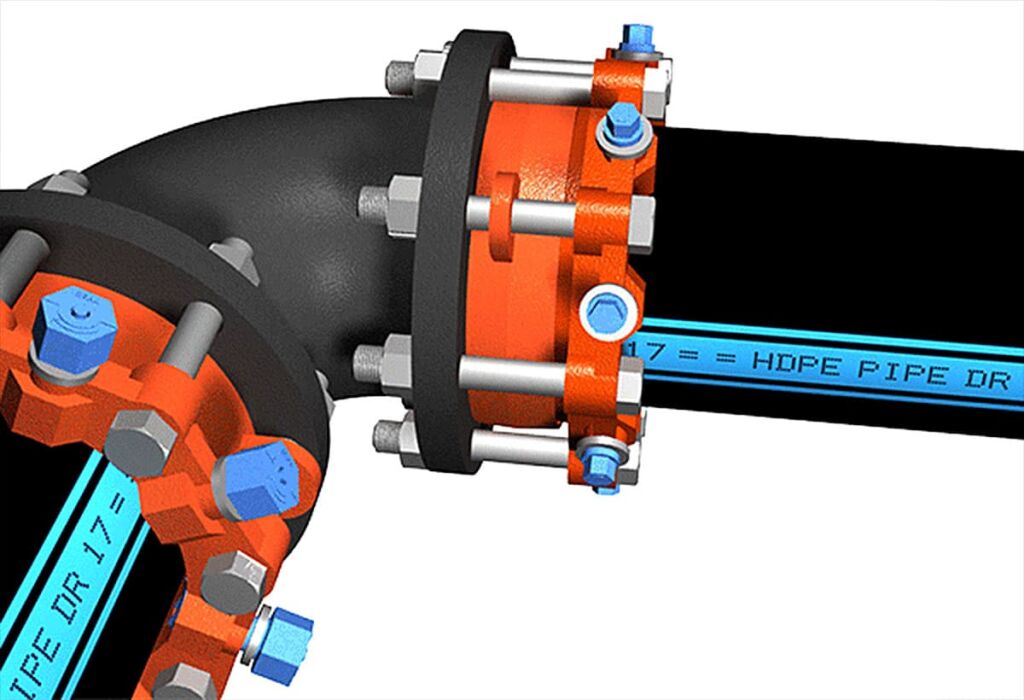

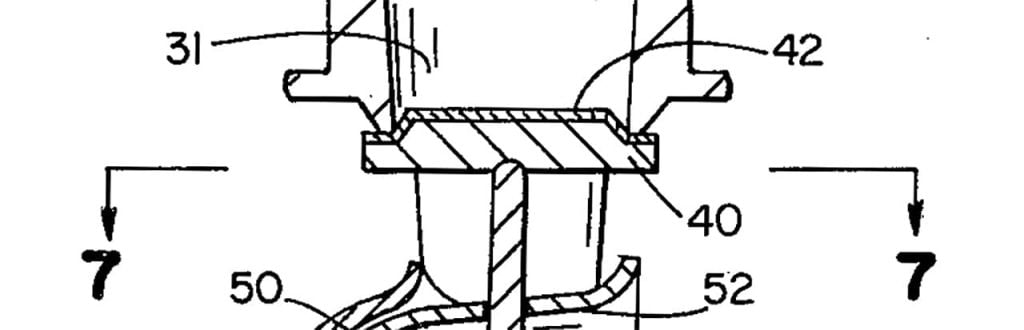

In rack sprinklers

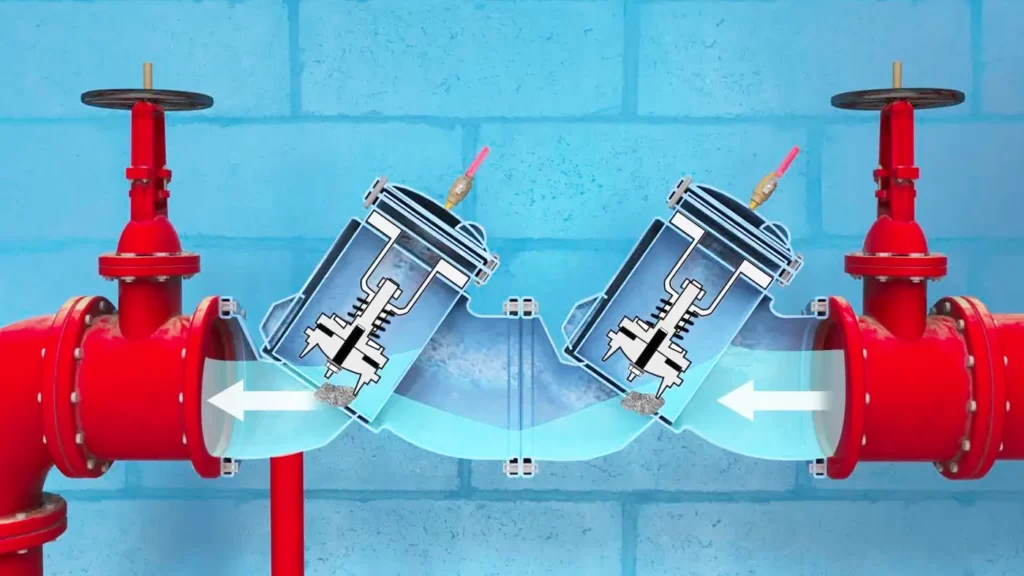

Warehouses are the only location where you will find sprinklers both at the ceiling level as well as in racks closer to ground level. This is a unique way to get water in the racks and applied to a fire before it is able to grow beyond the capabilities of the sprinkler system. Some higher hazard commodities will require in-rack sprinklers while other commodities have the option to include rack sprinklers and decrease the robustness of the ceiling sprinklers.

Prewetting

Most sprinkler systems rely on the concept of prewetting as a critical component in controlling a developing fire. Prewetting is when the sprinkler system activates and wets the fuel in front of the fires path, slowing down the fire growth. The issue with warehouses is that they can contain encapsulated products, which are impervious to prewetting (think of something that is wrapped in plastic on all sides). Due to this challenge the sprinkler system would have to be designed to be robust enough to be able to control a fire without prewetting.

Obstructions

In warehouses there is the potential for Early Suppression Fast Response (ESFR) sprinklers to be used. ESFR sprinklers rely on getting water to the fire quickly, this means both activating earlier than normal sprinklers and discharging water at a higher velocity. Because of this unique design feature, it makes it even more important to ensure that these sprinklers are clear of obstructions. If the sprinklers were prevented from reaching the fire during the early stages of fire growth the sprinkler could be ineffective.

Change management

Warehouses are likely to have items with varying commodity classifications being stored. Sprinkler design can account for this by either designing to the highest hazard commodity or by creating separate zones for higher and lower hazard commodities. Either way, when warehouses change what they are storing it is essential that the new products do not exceed the hazard level that the sprinklers were designed for.

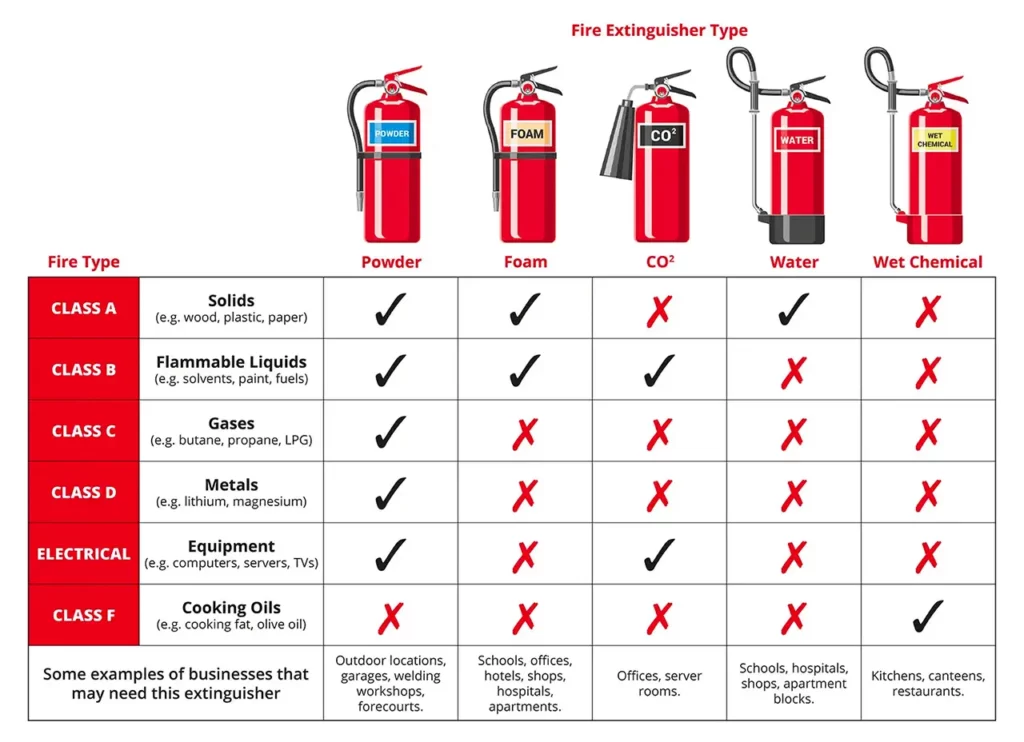

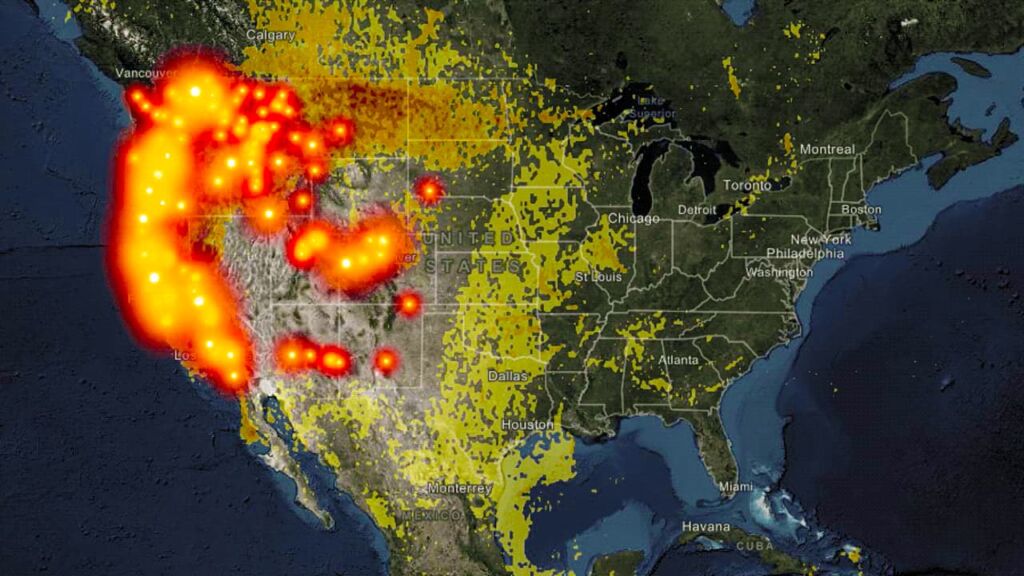

Flammable liquids and gasses

Another unique fire protection challenge for warehouses is that there might be large quantities of hazardous materials such as flammable liquids and gasses. These types of materials typically fall outside of the scope of NFPA 13 and into other NFPA documents such as NFPA 30, Flammable and Combustible Liquids Code, NFPA 55, Compressed Gases and Cryogenic Fluids Code, NFPA 52, Vehicular Natural Gas Fuel Systems Code or NFPA 58, Liquified Petroleum Gas Code. These codes contain requirements on the specific containers, building construction, and/or sprinkler design required for the storage of these more hazardous materials.

These are just some of the many unique fire protection challenges for warehouse and other similar distribution centers. For more information check out our Warehouse Fact Sheet. Also, come check out NFPA’s 125th Anniversary Conference series on November 16, which will feature presentations on automatic warehouse storage and retrieval systems, the importance of water supply assessment, a review of the changes to the 2022 edition of NFPA 13, and other relevant systems, storage, and suppression topics.

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.