Precision Fire Protection News

Power to Spare – Energy Storage Systems

As energy storage systems revolutionize power management, enforcers and responders tackle a host of emerging safety questions.

BY JESSE ROMAN

At his car company’s design studio in Hawthorne, California, Tesla CEO Elon Musk strode onto the stage to announce the launch of a new initiative called Tesla Energy. The project’s aim, he told an enthusiastic crowd, is nothing short of “a fundamental transformation of how the world works (and) how energy is delivered across Earth.”

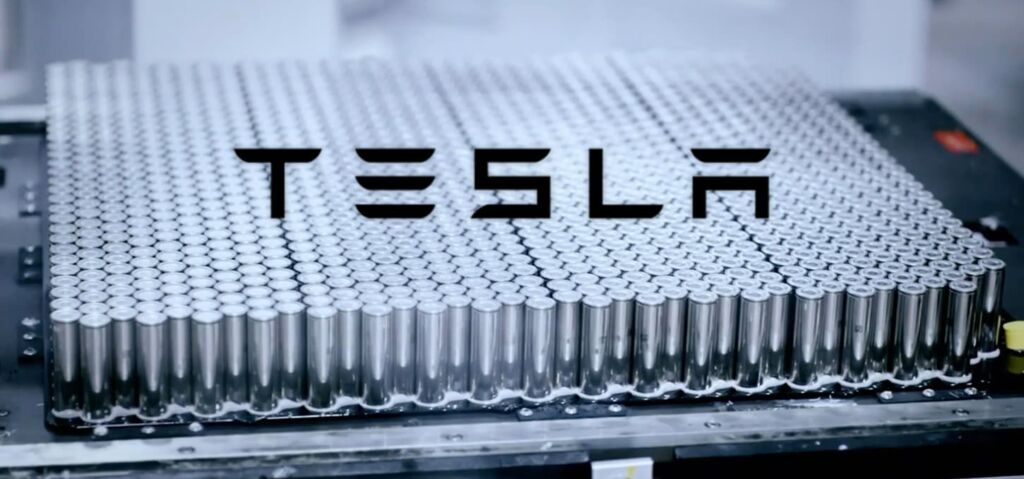

He then unveiled two rechargeable lithium-ion battery packs: the Powerwall, for residential use, and the Powerpack, designed for industrial use. The Powerwall, roughly the shape and size of a large boogie-board, is meant to hang on a wall in a garage or utility room, like a home appliance. The Powerpack, which resembles an oversized refrigerator, has already been installed at approximately 50 sites across the United States, Tesla says, and will soon be installed in at least two-dozen large office buildings in California, with more to come. Both batteries are based on technology that Tesla pioneered to power its Model-S vehicles, but instead of driving a wheel axle, the batteries are designed to store energy to power a home or office—or, if scaled up, a factory, airport, hospital, or even an entire electrical grid.

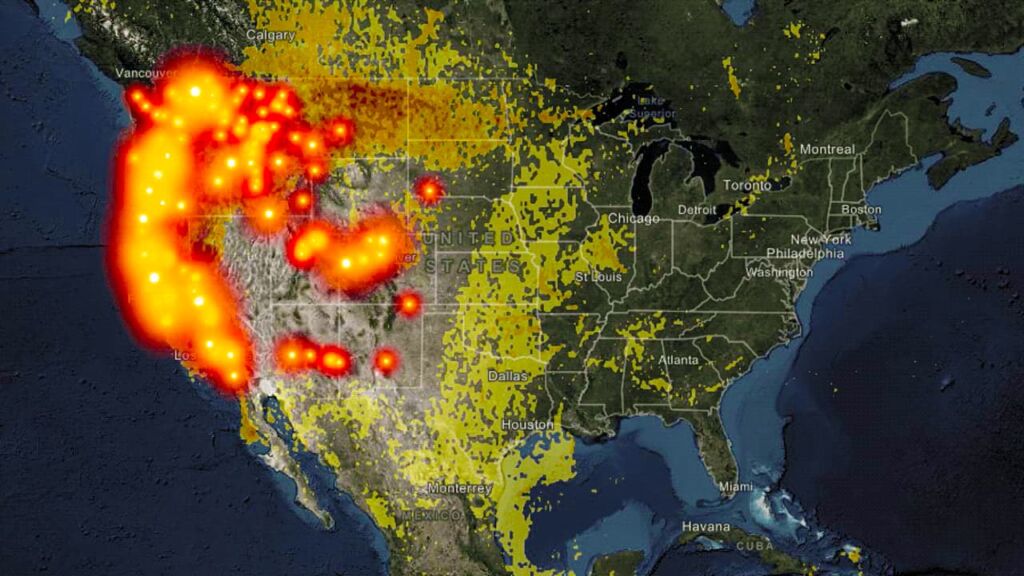

While Tesla Energy’s splashy launch caught the attention of a broad audience, big batteries—or energy storage systems (ESS) in industry parlance—have been gaining momentum for more than a decade. Clean-energy government incentive programs, such as New York’s Reforming the Energy Vision (REV) initiative and California’s Self-Generation Incentive Program, are having the intended impact of driving more widespread adoption of energy-storage technology. In fact, many observers believe the world is on the cusp of an energy-storage bonanza. The market research firm IHS Technology predicts that, by 2017, the annual installation of energy storage worldwide will be six gigawatts (GW), enough to power 6 million homes. IHS forecasts that annual energy storage installations will exceed 40 GW by 2022, up from just 0.34 GW in 2012 and 2013 combined.

The allure of batteries goes well beyond environmental altruism. The ability to store energy for use later means consumers and businesses can buy electricity when prices are low and use it when demand on the electric grid causes power prices to sharply rise. The practice, called peak shaving, can potentially save large energy users hundreds of thousands of dollars per year. Hospitals, data centers, airports, and other facilities with critical operations can use battery power to ensure business continuity in a disaster. Energy storage also appeals to individual consumers; when combined with solar energy, the systems promise potential freedom from the grid as well as backup power in an outage.

Energy storage is also fast becoming a critical resource for electric utility companies. Batteries allow utilities to have extra energy available to carry the electricity load during infrequent spikes in demand, such as during a summer heat wave in New York City. Without energy storage, the utilities’ only option to meet peak demand is more generation—turning on or building more power plants. It’s an inefficient system that results in total generation capacity far exceeding demand the majority of the year. “In fact, 95 percent of the time, substations are underutilized,” says Amaury De La Cruz, the demand management program director at ConEdison, one of the largest utilities in the United States. “But whenever there is an increase in peak demand, we need to invest in our system and build more wires and substations—energy storage allows us to defer that.” Tesla’s Musk has claimed that with properly deployed stationary storage, half of the world’s power plants could shut down with no impact on the electrical grid.

Tesla has already sold out of Powerwall and Powerpack batteries through 2016, taking orders worth more than $1 billion, Musk told reporters during an earnings report conference call. The company will ramp up production dramatically in 2017 when its $5 billion production facility, the Gigafactory, opens in the Nevada desert. “We believe we’re at the start of a rapidly growing deployment of these systems,” Scott Kohn, Tesla’s senior manager of battery safety and research and development, told me at a meeting at the company’s Palo Alto headquarters in the fall. “This is only the very beginning.”

While the case for energy storage is obvious, what’s less clear is what happens when something goes wrong. How do batteries of various chemistries and technologies react in a fire? How do firefighters make sure burning batteries are fully extinguished? How do responders handle a damaged battery that still contains energy? What are the risks to first responders and the public from exposure to toxic fumes, electricity, and other hazards associated with ESS if a fire or other incident were to occur? As an industry with vast potential to change the world gains prominence, public safety officials are scrambling to find answers.

Recognizing gaps

Two years ago, Lt. Paul Rogers, a hazardous materials expert with the Fire Department of New York (FDNY), was asked by his chief to attend a meeting on energy storage at FDNY headquarters in Brooklyn. He knew nothing about batteries before the meeting, but the information he came out with made him anxious.

To promote clean energy and solve an electricity supply crunch, New York State and the electric utility ConEdison were planning to incentivize customers in New York City to install ESS in their buildings. It likely meant that owners of buildings and businesses would soon seek to install various types of big batteries everywhere—high-rise buildings, homes, urban neighborhoods, business parks, substations, and all manner of spaces and occupancies in between. “I started thinking that the fire service really had no procedures for any of this stuff,” Rogers said. “I realized we had some major gaps.” Rogers has since become one of the country’s leading fire service experts on ESS, almost single-handedly pushing FDNY and the fire service forward on the issue.

Several months after that meeting, Rogers began talking to NFPA about the research and standards that existed to help FDNY vet the barrage of ESS applications the city expected to receive. Aside from some baseline information in NFPA 1, Fire Code, and NFPA 70®, National Electrical Code®, there wasn’t much.

As a result of those discussions, NFPA, the Fire Protection Research Foundation (FPRF), and FDNY partnered to host an ESS safety workshop in November at FDNY’s training facility on Randall’s Island. The event brought together about 60 leading professionals from government, the insurance industry, the fire service, utilities, the ESS industry, the codes and standards world, and others to discuss the current state of ESS, as well as gaps in safety knowledge, codes and standards considerations, and research needs. “We needed some sort of tangible takeaway—we were adamant about that,” Rogers told me of the decision to hold the workshop. “I thought we captured some really good information.”

A report will be generated from the proceedings to help New York and other communities better evaluate ESS installation applications. The report will also inform codes and standards development, research, ESS design, and product testing. The proceedings are available on the FPRF’s website, nfpa.org/foundation.

Work on ESS is happening elsewhere, too. In December, 2014, the U.S. Department of Energy (DOE) published its “Energy Storage Strategic Plan,” which identifies three key needs: standardized methods to validate system safety; updated codes, standards, and regulations for ESS safety; and procedures to safely respond and handle ESS emergencies and incidents. NFPA, Underwriters Laboratories (UL), the FPRF, and several other entities are all working to address those gaps.

At least two outside groups have indicated that they intend to submit a request for NFPA to develop a new ESS standard to help first responders, manufacturers, and installers better understand and mitigate potential ESS hazards. Such a document would likely address installation, siting, testing, maintenance, ventilation, and fire protection, among other things, said Rich Bielen, NFPA’s manager of Fire Protection Systems Engineering. If NFPA’s Standards Council green-lights the project, it would likely take about three years for the first edition to emerge, Bielen said.

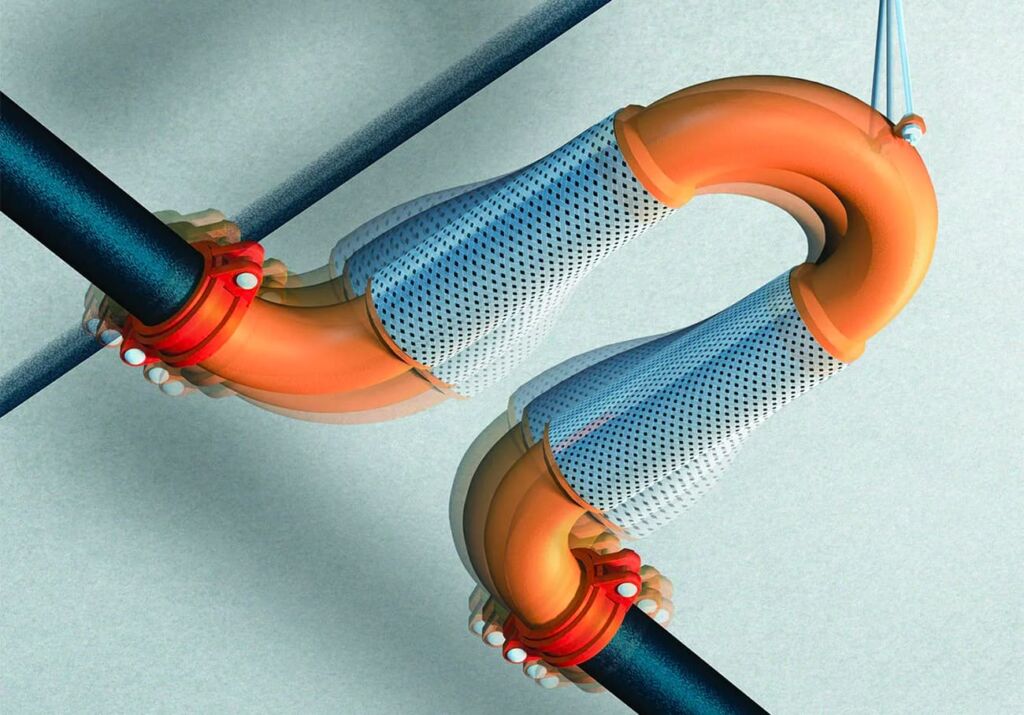

One approach could be to create an entirely new standard; another could be to update existing codes and standards to include more on ESS—such as adding ESS suppression guidance to NFPA’s suppression documents—and then creating a standard that pulls all of the information together. That effort is underway now in NFPA 1. An extensive overhaul of Chapter 52 of the code is being explored to provide more detail on the various battery chemistries used in ESS and to establish the protection measures that go with those technologies. Some of the work will involve collecting existing information, while much of it requires new research and a lot more discussion.

Dynamic technology

Developing protocols for evaluating ESS systems and creating emergency procedures is a complex task, in part because the target keeps moving—ESS technology is constantly expanding and evolving. The roots of ESS go back to the 1930s and pumped-hydroelectric storage, a mechanical form of energy storage that has played a significant role in the reliability of the electric grid. The concept is simple: during periods of high electric demand, a large reservoir of water is drained into a lower reservoir, turning a turbine in the same manner as a conventional hydropower station. Pumped hydro still accounts for 95 percent of the world’s installed stored energy capacity, but that’s changing. Increasing needs for more flexible and reliable energy supplies, the growth in renewable energy, more stringent environmental regulation, and recent technological advances have all paved the way for the rapid rise in electro-chemical energy storage in the form of big batteries.

In 2003, the Golden Valley Electric Association, an electric utility near Fairbanks, Alaska, undertook one of the largest ESS battery projects to date, installing a 1,500-ton nickel-cadmium battery to provide backup power to its 44,000 customers. The battery, still one of the world’s most powerful, can provide as much as 27 megawatts (MW) of power for 15 minutes—enough time for utility crews to start up local generation in case there is an issue with the power supply from primary power plants further away. In 2014 the battery responded to 78 events, preventing a total of 263,489 customer outages, according to Golden Valley.

More recent technological breakthroughs have reduced costs and allowed energy storage to also become viable for businesses and individual homeowners. In 2010, the California Public Utilities Commission awarded $1.8 million to SolarCity, a residential photovoltaic panel installer, to study the feasibility of using batteries to store the electricity generated by rooftop solar arrays. “As soon as distributed solar starts providing 5 to 10 percent of demand, its intermittent nature will need to be addressed,” Peter Rive, SolarCity’s co-founder and chief operating officer, said at the time. “We think in the years ahead this will be the default way that solar is installed.”

“If your goal is to build a meaningful solar business that is durable over time, you have to assume that that solar business is going to morph into a solar-plus-storage solution,” Steve McBee, chief executive of NRG Home, one of the largest independent power producers in the U.S., said recently. “That will be mandatory at some point.”

That future is already emerging.

More industries are turning to energy storage either to complement their wind and solar panel systems or to cut their electricity bills by peak shaving. The U.S. Department of Energy’s Global Energy Storage Database currently lists nearly 1,400 commercial ESS projects now deployed around the world in a variety of settings and applications. Those include an advanced lead acid battery storage system at Ford Motor’s manufacturing plant in Dearborn, Michigan; thermal ice energy storage at the Toronto Zoo; sodium-sulfur battery storage at a wind farm in Japan; flow batteries on the 25th floor of the Metropolitan Transit Authority headquarters in Manhattan; and a fleet of 24 hybrid-electric office buildings in California using 10 MW of lithium-ion energy storage. In New York City alone, ESS projects of at least five different battery chemistry types have been approved in both indoor and outdoor locations.

“Batteries are being installed more and more where people work, play, and sleep,” said Roger Lin, the director of product marketing at the Massachusetts-based NEC Energy Solutions, which has installed battery systems around the globe. “There is a layered approach to safety that needs to be taken by everybody in the industry. If we are not doing this the right way, it will slow down adoption, but we have to do so without impacting reliability. There is a balance, and we have to figure out what it is.”

The specific combination of hazards inherent in ESS is somewhat unique, but the individual threats—arc flash, fire, combustion, voltage, and toxicity—“are all hazards that already exist in places like New York City, and are associated with systems first responders are comfortable with, such as substations and chemical storage,” said David Rosewater, an engineer at Sandia National Laboratories, who studies ESS.

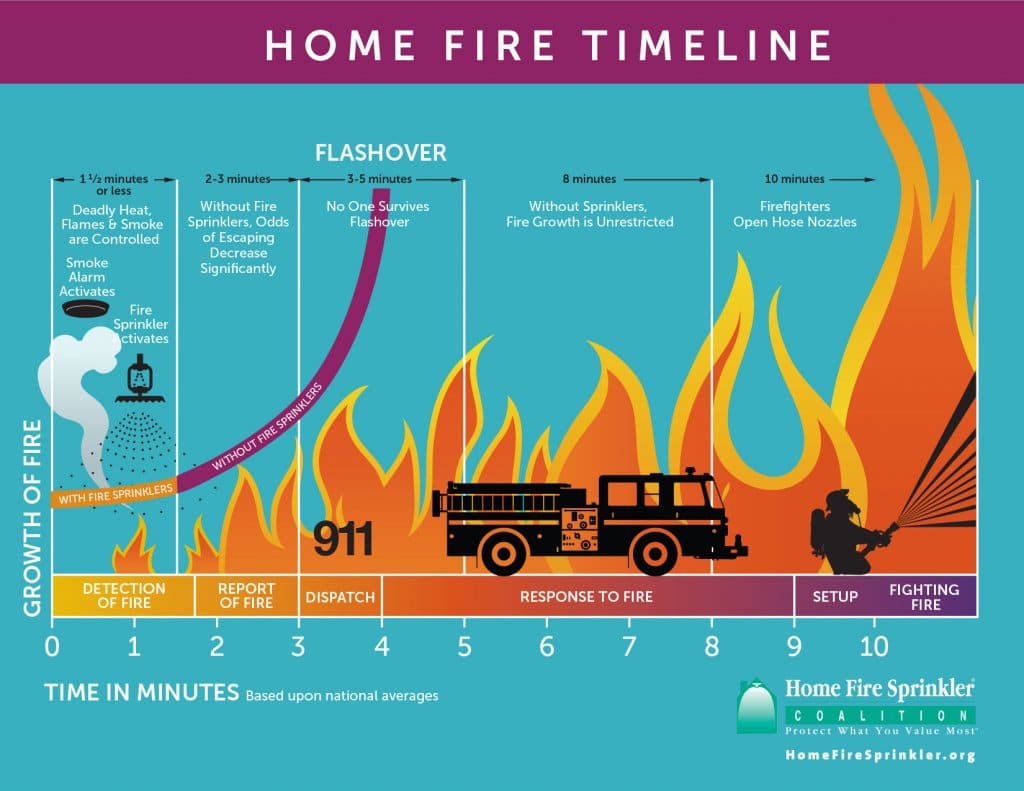

For first responders, however, perhaps a bigger concern than the ESS itself is the migration of the systems into homes, offices, and factories. “If you respond to an ESS at a power plant, you understand that going in and you know to be cautious—it has typically been a hands-off approach,” said Ken Willette, a former fire chief and the division manager for Public Fire at NFPA. “But when you put ESS into homes and occupied buildings, there is a different risk analysis—you may need to interact with it to contain a fire or make a rescue. Responders are asking, ‘What do I need to know to make that risk analysis?’ It’s about understanding how the system works at a basic level.”

If NFPA’s ESS workshop in New York was any indication, stakeholders agree when it comes to the importance of getting ESS right, along with its related safety issues—a single event can give an emerging technology a black eye that’s tough to recover from.

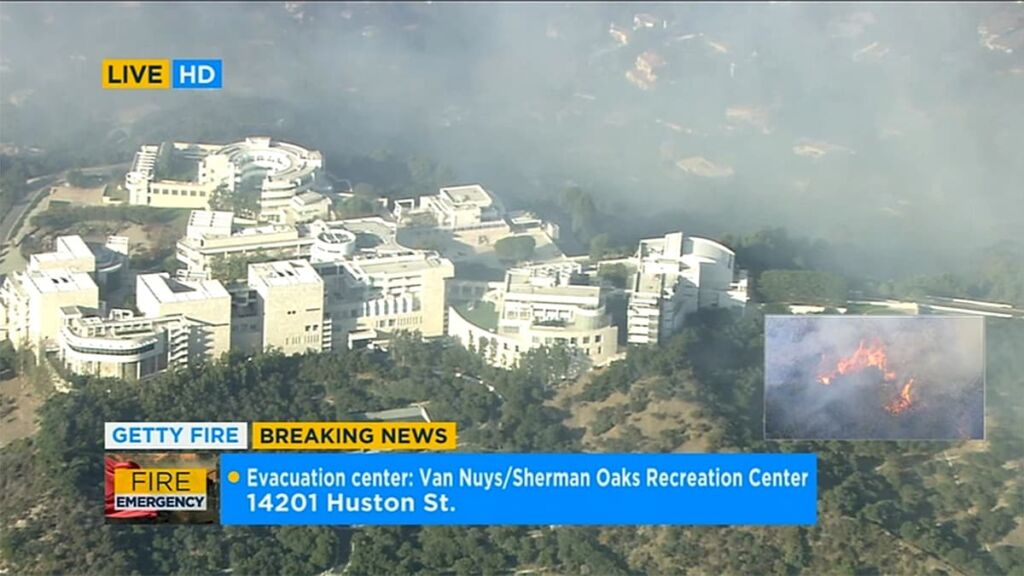

In 1973, for example, an explosion inside a 600,000-barrel liquid natural gas (LNG) tank on Staten Island lifted off the facility’s concrete roof, which fell and crushed 40 people below. The tragedy left many questioning the safety of transporting and storing LNG near urban areas. Soon after, the state outlawed the construction of new LNG facilities, a ban that lasted more than 40 years. In January, 2015, New York’s state Department of Environmental Conservation announced it was lifting the ban—but not in New York City. “The moral of that story is to work with us so we understand what the risks are,” Rogers said to the ESS workshop participants, “and we will work with you to make sure everyone goes home safe and the occupants stay safe.”

Codes and standards developers and researchers are trying to do their part to prevent a similar incident involving ESS. In addition to NFPA’s work on a potential new standard, in September NFPA received a $762,000 Assistance to Firefighters grant from FEMA that will be used to develop a trainer safety course on ESS, as well as a free interactive web-based course on ESS safety awareness for first responders. The initiative will involve working with FPRF, clean energy consulting firm Strategen, and other research groups to further develop ESS best practices for first responders. The web course is expected to be available at evsafetytraining.org and nfpa.org by late summer.

Meanwhile, UL is in the final stages of completing a new standard, UL 9540, which covers ESS safety testing. The new standard references a number of existing UL standards, including UL 1973, which addresses the safety of lithium-ion battery ESS. UL 9540 is expected to be finalized in early 2016, but product testing and certification to the draft standard have already begun. “These listings by UL ensure an even playing field, that there be a minimum level of safety out there,” said Rosewater, who was on the committee that developed the standard.

Research also continues to fill in some of the knowledge gaps. The FPRF will soon release a report that provides an overview of the ESS technology now being deployed and a hazard assessment for each. Part of that project involved partnering with Tesla recently on full-scale burns of Powerpacks in the Nevada desert. Testing explored both external and internal fire attack scenarios and involved measurement of temperatures, heat release rates, and vent gas composition.

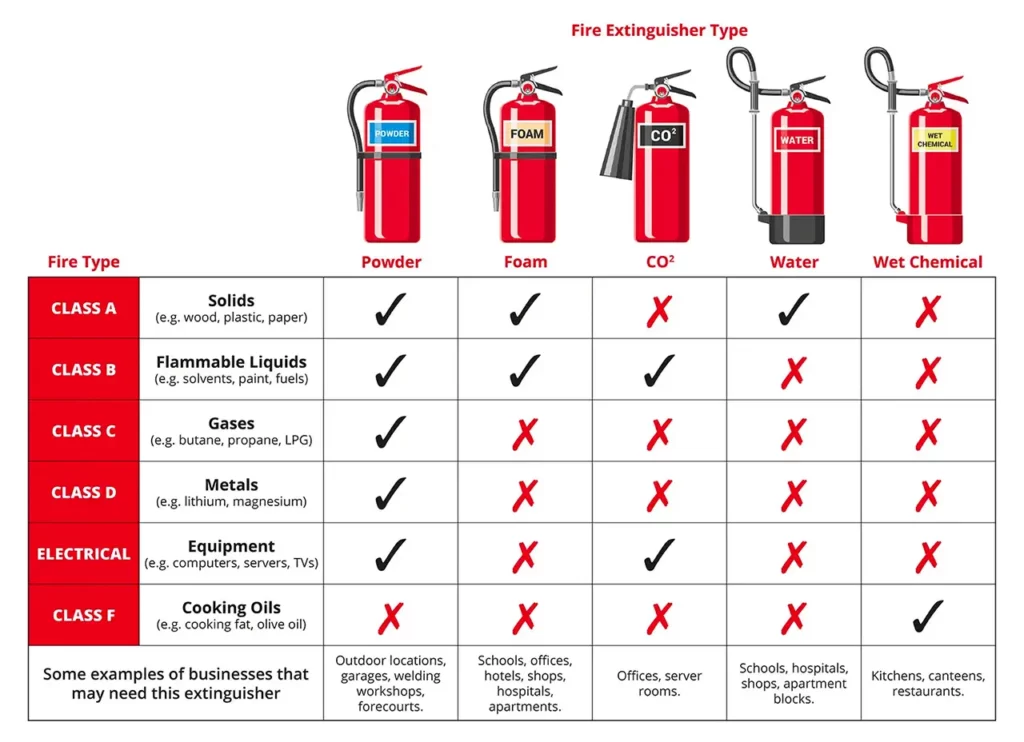

Additionally, ConEdison has partnered with FDNY on small-scale battery-cell burn tests. The tests will address six different ESS technologies and measure several key variables: the heat release rate; what harmful gasses and liquids may come off of and out of the batteries during a fire; which suppression agents are effective in suppressing or extinguishing a battery fire; and if the fires produce any arcing, thermal runaway, or other events, and under what conditions. The tests will be used to create a computer model that can predict what would happen in full-sized fires. The final report is expected to be finished and publically available by late spring.

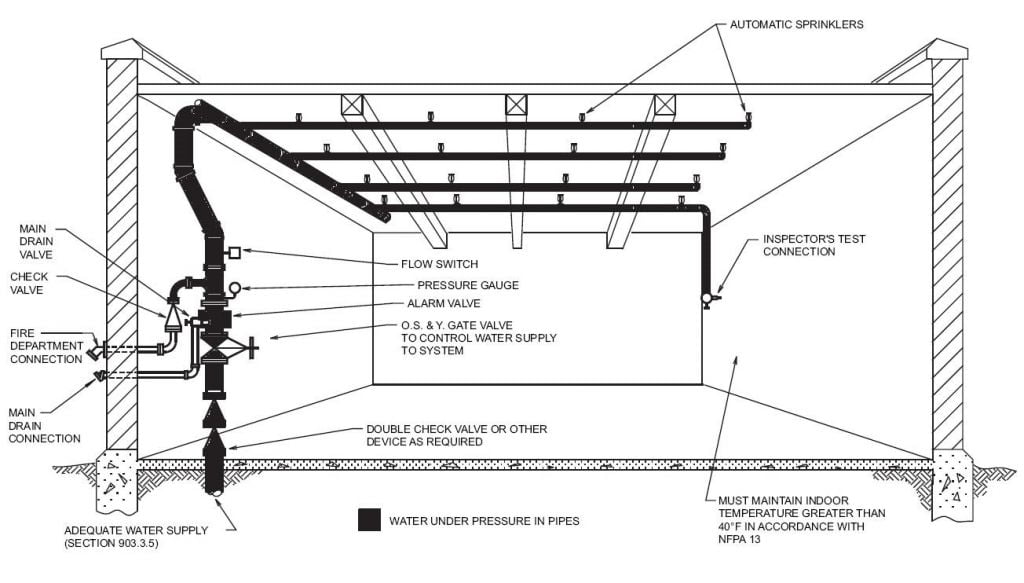

Even as progress occurs, many safety experts believe that there is still a long way to go to fully understanding adequate ESS protection and response. At NFPA’s ESS workshop in New York, attendees split into breakout groups to consider safety topics for facility and building design, ESS and built-in fire protection systems, and emergency response tactics and strategies. The roughly 20 participants in the emergency response group included FDNY chiefs, ESS manufacturers, NFPA staff, ConEdison representatives, insurers, and others. The discussion was enthusiastic and productive, and also demonstrated the complexities of this sprawling issue. Topics ranged from electrocution risks of water from sprinklers pooling on the floor around an ESS system, to whether fire departments should require owners to disclose that they have ESS in their homes or businesses. At least one participant advocated for a national ESS tracking system. The issue of lithium-ion batteries igniting after being damaged, or reigniting after a fire has been extinguished, was raised. There was discussion on what kind of signs or markings should be required on the systems to alert first responders of the dangers associated with ESS. A remote shut-off switch should be a requirement, others said. And there were many questions. What about ventilation of potentially toxic gasses in an enclosed space—where should they go? What about system overhaul after a fire incident?

“The fire service is missing data and information about how these things react in a fire, but we’re getting there,” Rogers said. “The fire service is not opposed to any new technology—we just want to know what we are up against so we can manage the risks. Once we figure it out, we’ll make it work. We always do.”

JESSE ROMAN is staff writer for NFPA Journal. He can be contacted at [email protected].

PEOPLE We Protect

Our Distributors and Suppliers

Experience

Our team started in the fire protection industry over 20 years ago. Since then we have grown into a statewide fire protection construction leader. Our team of project managers, engineers, designers, inspectors, installers, and technicians all share a passion for quality work and high standards. Precision Fire Protection understands the need to complete projects with integrity, safety, and precision!

Dedication

Our mission is to provide our customers with timely, high quality, affordable fire protection services that are guaranteed. We strive to achieve our client’s complete satisfaction. We are relentless in applying the highest ethical standards to ourselves and to our services and in communications with our customers. We aim to fulfill that mission in everything we do.

Precision

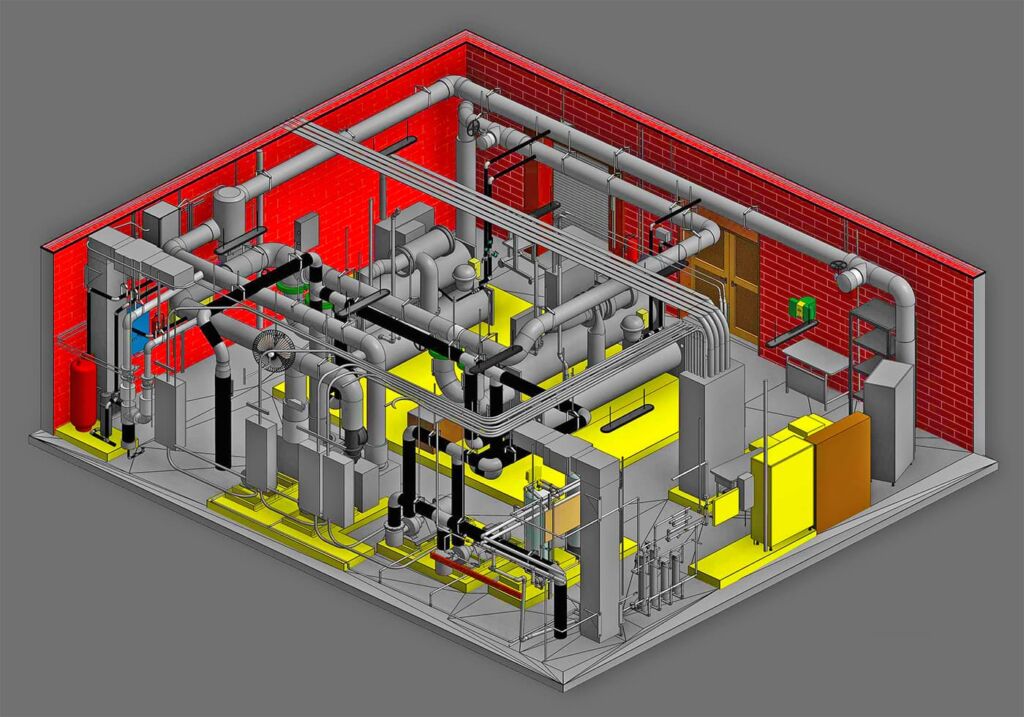

Precision Fire Protection keeps its team together, even when it's not. Just as vital as field personnel’s tools are, our project managers are equipped with the latest software to manage projects. Our project managers send dailies, RFIs, and plan revisions to the cloud so that everyone has access no matter where they are. Being connected is our way of ensuring every project goes smoothly.

Safety

Our team of multi-certified managers and supervisors are highly experienced in job safety. Our managers are OSHA certified to handle each project with care and sensitivity to every unique job site. By ensuring on-site safety on every project we work on throughout Southern California, Precision Fire Protection has developed positive relationships with our General Contractors.